Feb . 13, 2025 17:01 Back to list

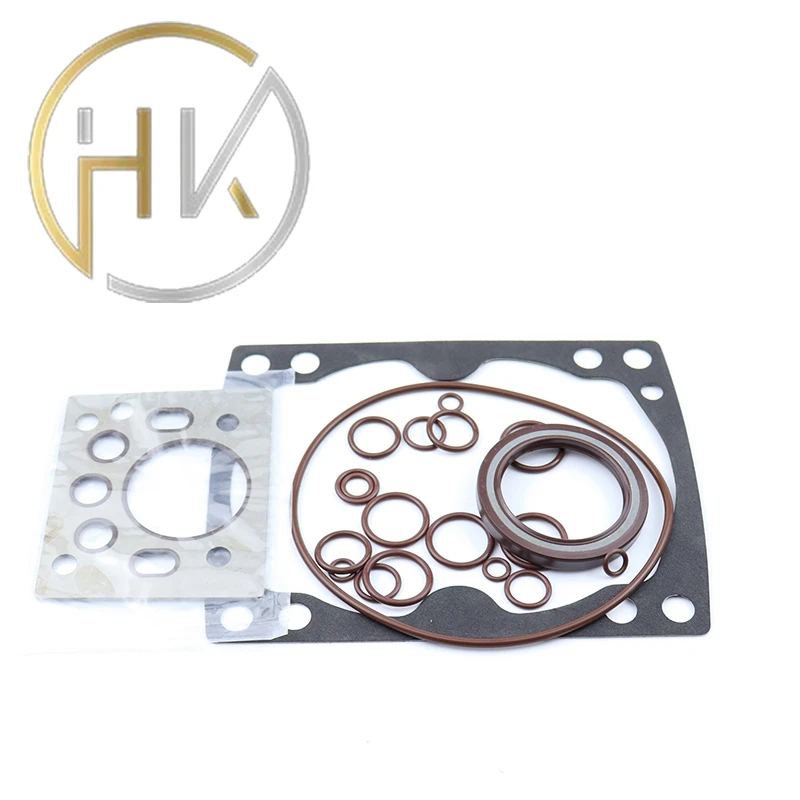

170×200×15 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Real-world Experience from industries employing high-temp oil seals provides invaluable insights into their practical applications. In the automotive sector, for instance, modern engines equipped with turbochargers operate at elevated temperatures where ordinary seals would fail. High-temp oil seals ensure that these engines run efficiently, reducing the risk of overheating and oil loss. Similarly, in aerospace applications, where safety and performance are non-negotiable, these seals offer reliable solutions that withstand the extreme conditions encountered during flight. Trustworthiness in the industry also hinges on after-sales support and technical assistance. Leading manufacturers offer comprehensive support services, including installation guidance, troubleshooting, and maintenance tips. This level of customer service not only enhances product longevity but builds lasting relationships with clients who can rely on expert advice tailored to their specific needs. In conclusion, high-temperature oil seals are pivotal to the seamless operation of machinery subjected to harsh thermal conditions. The Experience and Expertise demonstrated by manufacturers, combined with compliance to authoritative standards and robust support systems, fortify customer confidence in these essential components. As industries continue to push technological boundaries, the demand for reliable high-temperature oil seals will persist, underscoring the significance of their role in industrial success and innovation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories