Dec . 24, 2024 12:14 Back to list

high temp oil seal

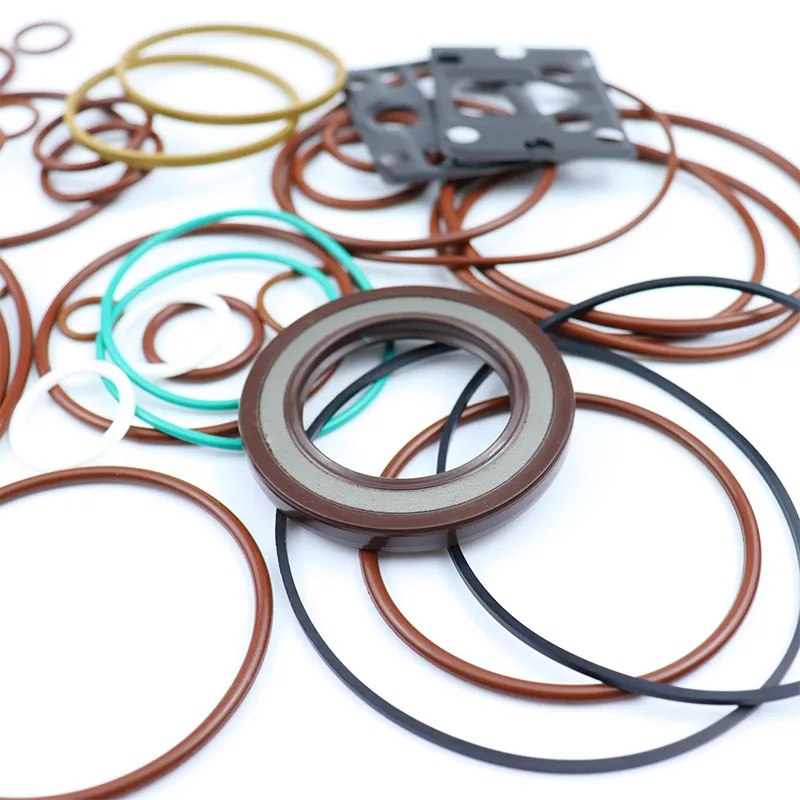

High Temperature Oil Seals Ensuring Reliability in Challenging Environments

In various industrial applications, equipment is often subjected to extreme conditions, including high temperatures and aggressive lubricants. In such scenarios, conventional sealing solutions may fail to perform effectively, leading to operational inefficiencies, leaks, and even catastrophic failures. This is where high temperature oil seals come into play, providing dependable sealing solutions designed for demanding environments.

Understanding High Temperature Oil Seals

High temperature oil seals are specially engineered components that prevent the leakage of lubricants in conditions where temperatures can soar significantly beyond the norm. These seals are manufactured from advanced materials capable of withstanding heat, chemicals, and harsh working conditions. Common materials include fluoroelastomers (FKM), silicone, and high-performance thermoplastics which are designed to maintain their integrity even at elevated temperatures.

Key Features and Benefits

1. Temperature Resistance High temperature oil seals can typically operate in environments with temperatures exceeding 200°C (392°F). This is crucial for applications in automotive, aerospace, and manufacturing industries where high operational temperatures are the norm.

2. Chemical Compatibility These seals are often designed to resist not only high temperatures but also a wide range of chemical substances, including oils, fuels, and various lubricants. This compatibility helps prevent degradation and ensures a longer service life.

3. Durability and Longevity The robust materials used in high temperature oil seals contribute to their durability. They resist wear and tear, reducing maintenance requirements and extending the life of machinery and equipment.

4. Reduced Friction Properly designed oil seals reduce friction between moving parts, thereby improving efficiency and contributing to the overall performance of machinery.

high temp oil seal

5. Customizability Manufacturers often provide customization options to accommodate specific industry needs, ensuring that the seals fit perfectly in their designated applications.

Applications of High Temperature Oil Seals

High temperature oil seals find applications across various industries, including

- Automotive Industry In engines and transmissions, seals prevent oil leaks which can cause overheating and reduce efficiency. - Aerospace Engineering High performance seals are necessary for preventing leaks in aircraft engines and hydraulic systems where extreme conditions persist. - Manufacturing Machinery that operates at high temperatures, such as pumps, compressors, and turbines, relies on effective sealing solutions to maintain proper lubricant levels. - Oil and Gas Industry In drilling operations where equipment is exposed to high pressure and temperature, robust sealing solutions are vital for operational safety and efficiency.

Challenges and Considerations

While high temperature oil seals are essential, selecting the right seal for a specific application requires careful consideration. Factors such as the type of fluid being sealed, temperature extremes, pressure levels, and environmental conditions must be taken into account. Furthermore, installation techniques and maintenance practices impact the performance of these seals, highlighting the importance of proper guidance from manufacturers or industry experts.

Conclusion

High temperature oil seals are a critical component in ensuring the reliability and efficiency of machinery operating in challenging environments. Their ability to withstand extreme temperatures and corrosive substances makes them indispensable in industries where performance is paramount. As technology continues to advance, the development of even more resilient and efficient sealing solutions will play a key role in enhancing operational capabilities and reducing maintenance costs across various sectors. Investing in the right high temperature oil seals not only ensures the longevity of equipment but also plays a vital role in maintaining productivity and profitability in increasingly demanding industrial landscapes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories