Dec . 17, 2024 23:10 Back to list

high temp oil seal

High Temperature Oil Seals An Overview

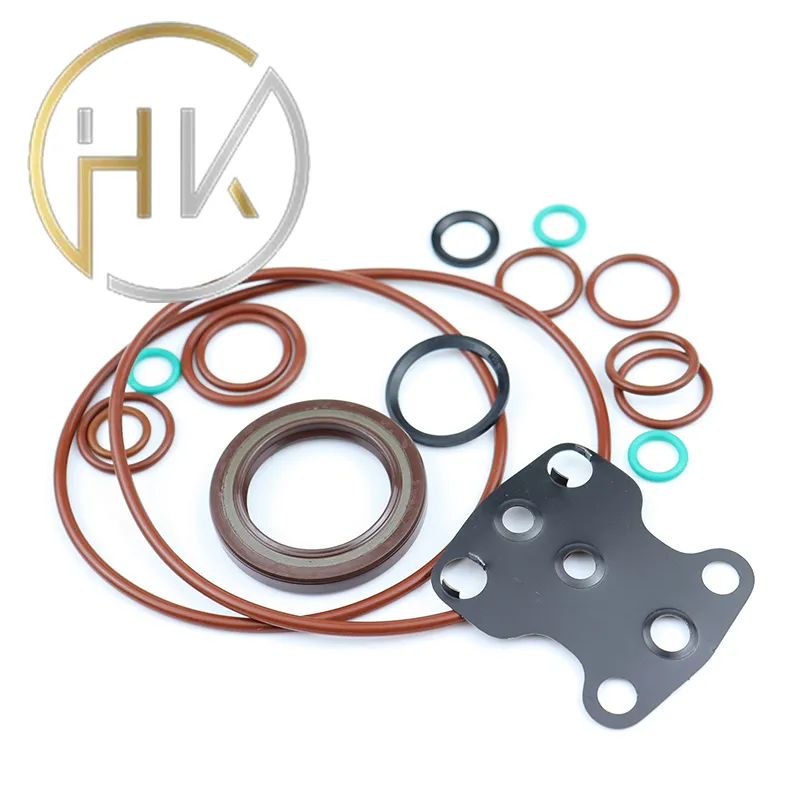

High temperature oil seals are critical components in various industrial applications where machinery operates under extreme conditions. These seals play a crucial role in preventing the leakage of lubricants while ensuring that contaminants do not enter the machinery. With the increasing demands for efficiency and durability in modern engineering designs, the importance of high temperature oil seals becomes even more pronounced.

Understanding Oil Seals

Oil seals, also known as shaft seals or rotary seals, are designed to retain lubricants and exclude dirt, dust, and moisture from the machinery while allowing for the optimal operation of rotating shafts. They are typically made of rubber or thermoplastic materials, which provide flexibility and resilience. However, the standard materials may not withstand high temperatures, leading to the development of specialized high temperature oil seals.

Materials Used

High temperature oil seals are manufactured using advanced materials that can endure extreme temperatures, typically ranging from 120°C to 300°C (248°F to 572°F). Common materials include fluorocarbon elastomers (FKM), silicone rubber, and polyacrylate elastomers. These materials possess excellent thermal stability, chemical resistance, and mechanical properties, making them suitable for high-performance applications.

FKM, for example, is known for its exceptional heat resistance and ability to withstand aggressive fluids, making it a preferred choice in automotive and aerospace industries. On the other hand, silicone rubber is favored for its flexibility at varying temperatures, while polyacrylate elastomers provide a balanced performance for moderate temperature applications.

Applications

high temp oil seal

High temperature oil seals find applications across various industries, including automotive, aerospace, manufacturing, and oil and gas. In automotive applications, they are used in engines, transmissions, and differential assemblies, where they help maintain lubricant levels and prevent the entry of contaminants.

In aerospace, high temperature oil seals are vital in engines and hydraulic systems, ensuring optimal performance under high-pressure and temperature conditions. In manufacturing processes that involve heavy machinery, these seals are necessary to maintain operational efficiency and reduce maintenance costs.

Performance and Reliability

The performance of high temperature oil seals is significantly influenced by their design and material selection. Engineers must consider factors such as shaft speed, temperature fluctuations, and the type of fluids—whether they are lubricants or contaminants—when selecting the appropriate seal.

A reliable high temperature oil seal must maintain a tight seal even under extreme conditions, preventing oil leaks that can lead to costly downtime or machinery failure. Regular maintenance and inspection are crucial to ensuring the longevity and effectiveness of these seals.

Conclusion

High temperature oil seals are indispensable components in engineering applications where reliability and performance are paramount. The development of advanced sealing materials has led to increased efficiency and reduced operating costs across industries. With continuous advancements in material science, the future of high temperature oil seals looks promising, ensuring that machinery operates smoothly and efficiently even in the most challenging environments.

Ultimately, selecting the right high temperature oil seal requires a thorough understanding of the specific application requirements and conditions. By prioritizing quality and performance in seal selection, industries can significantly enhance their operational reliability and minimize maintenance challenges.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories