Feb . 12, 2025 19:06 Back to list

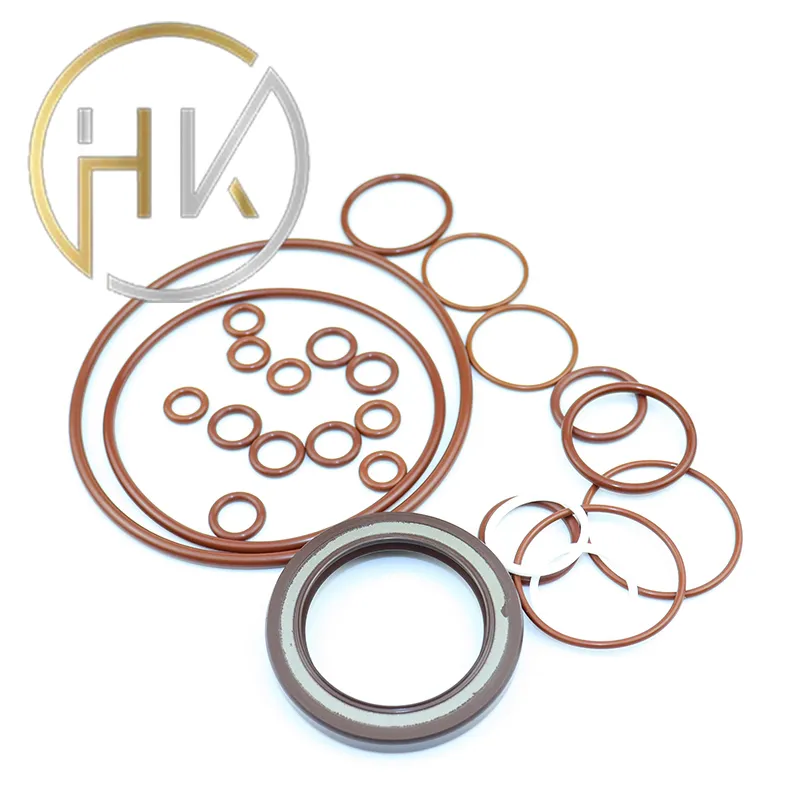

high temperature o ring kit

The authoritativeness of brands offering high temperature O-ring kits often stems from their contribution to industry standards and innovations. Established manufacturers, leveraging years of research and development, assure customers of the kits' reliability and performance. Check for certifications and compliance with international standards, as these are indicative of the product’s acceptance within the industry. A reputable brand backs its products with rigorous testing and validation processes, offering an extra layer of assurance. This trust in the brand’s authority on O-ring technology translates into lower risks of equipment failure, adding long-term value to business operations. Trustworthiness also plays a pivotal role in choosing the right high temperature O-ring kit. Not only should the kits be sourced from credible manufacturers, but post-sale support and customer service are equally critical. A trustworthy supplier provides detailed product information, installation guidelines, and maintenance tips, facilitating the correct usage of the O-rings. Additionally, customer feedback and reviews offer practical insights into the product's real-world performance and reliability. Establishing a relationship with a reliable supplier means they bring knowledge and support, helping clients optimize their equipment's performance and longevity. In conclusion, high temperature O-ring kits are more than just components; they are a testimony to engineering prowess and technological advancement. Their role in safeguarding operations across various high-demand industries underscores their value. Companies prioritizing operational excellence should rely on kits that promise high performance, durability, and reliability. This strategic choice not only ensures a return on investment but also upholds the quality standards that define industry leadership. Therefore, when selecting O-ring kits, focus on experience, expertise, authoritativeness, and trustworthiness to secure the best solution for high temperature sealing challenges.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories