Dec . 16, 2024 23:01 Back to list

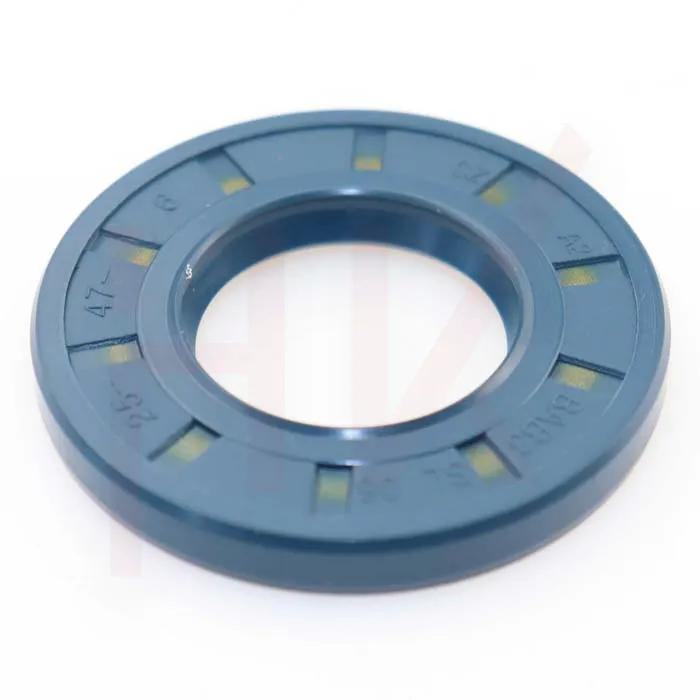

high temperature oil seal

High Temperature Oil Seal An Essential Component in Modern Machinery

In the realm of mechanical engineering, reliability and efficiency are paramount. One of the unsung heroes contributing to these qualities is the high temperature oil seal. This crucial component plays a significant role in extending the lifespan of machinery and ensuring optimal performance, especially in high-temperature applications.

What is a High Temperature Oil Seal?

An oil seal is a device used to prevent the leakage of fluids, such as oil, grease, or hydraulic fluids, from machinery. High temperature oil seals are specifically designed to withstand elevated temperatures, often exceeding 100 degrees Celsius (212 degrees Fahrenheit). These seals are constructed from materials that can endure high thermal stress and resist deformation while remaining flexible enough to provide a proper sealing function.

The most common materials used in high temperature oil seals include fluorocarbon (FKM), silicone rubber (VMQ), and other advanced polymers that can handle extreme conditions. These seals are engineered to maintain their physical properties even when subjected to heat and aggressive chemical environments, making them essential in various industrial sectors.

Applications of High Temperature Oil Seals

High temperature oil seals find applications across a wide array of industries. Here are some prominent examples

1. Automotive Industry In vehicles, oil seals are vital components in engines, transmission systems, and differentials. They help to maintain the integrity of lubricants within these systems, preventing leaks that can lead to component wear and failure.

2. Aerospace The aerospace industry requires components that can operate reliably under extreme temperatures and pressures. High temperature oil seals are used in engines and hydraulic systems to ensure that lubricants remain contained, thus reducing the risk of failure during flight.

3. Manufacturing Equipment Many industrial machines and manufacturing equipment require high performance and dependability. Oil seals help maintain lubrication in motors, pumps, and gearboxes, ensuring smooth operations and minimizing downtime caused by leaks.

high temperature oil seal

4. Oil and Gas Industry In the extraction and processing of oil and gas, equipment is frequently exposed to harsh temperatures and corrosive substances. High temperature oil seals are utilized to protect machinery and prevent fluid loss in these demanding environments.

Benefits of High Temperature Oil Seals

The advantages of using high temperature oil seals are plentiful

- Enhanced Durability These seals are engineered to withstand extreme conditions, leading to reduced wear and tear. Their longevity contributes significantly to the overall lifespan of machinery, allowing for less frequent replacements.

- Leak Prevention High temperature oil seals effectively prevent the escape of lubricants, which is crucial for maintaining efficiency and safety within mechanical systems. This leak prevention reduces the likelihood of environmental contamination and minimizes maintenance costs.

- Operational Efficiency By maintaining proper lubrication within machinery, high temperature oil seals help ensure that components function optimally. This efficiency can lead to energy savings and improved performance across machinery.

- Versatility Available in various sizes and designs, high temperature oil seals can be customized to fit a wide range of applications, offering solutions for both standard and specialized needs.

Conclusion

As industries push the boundaries of efficiency and performance, high temperature oil seals emerge as a key component in achieving these goals. Their ability to prevent leaks, withstand extreme conditions, and enhance the durability of machinery cannot be overstated. In an ever-evolving technological landscape, the importance of high temperature oil seals will only continue to grow, making them indispensable in modern machinery. Whether in automotive engines, aerospace applications, or industrial manufacturing, these seals play a critical role in ensuring reliability and efficiency, laying the groundwork for advancements in various sectors.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories