Oct . 18, 2024 13:49 Back to list

High-Performance Sealing Solutions for High-Pressure Shaft Applications and Improved Reliability

The Importance of High Pressure Shaft Seals in Industrial Applications

High pressure shaft seals play a crucial role in various industrial applications where rotating shafts are involved. These seals are designed to prevent the leakage of fluids or gases while maintaining the integrity of the system under high-pressure conditions. Understanding the significance of high pressure shaft seals can help industries ensure optimal performance and longevity of their machinery.

What are High Pressure Shaft Seals?

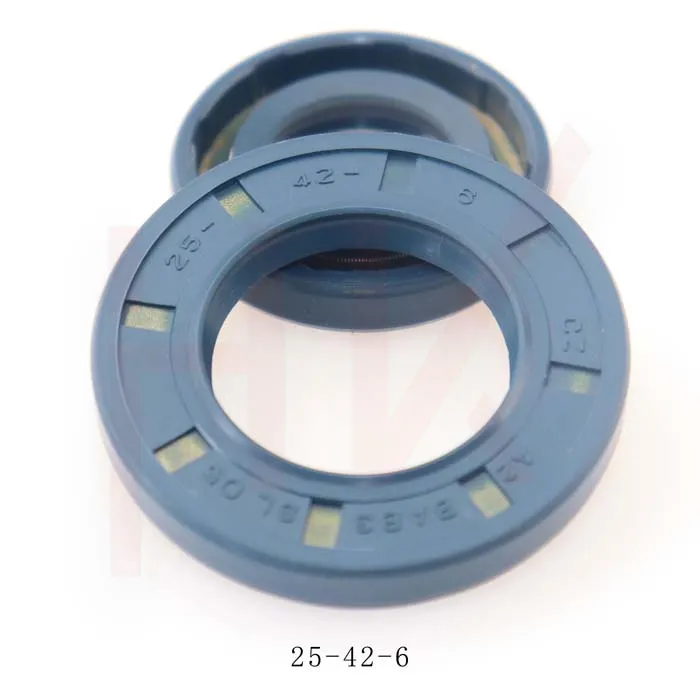

High pressure shaft seals are components that provide a barrier between the rotating shaft and the housing, effectively preventing the escape of lubricants or the ingress of contaminants. They are commonly used in applications such as hydraulic pumps, compressors, and turbines, where operating pressures can reach significant levels. The seals are typically made from durable materials that can withstand extreme temperatures and pressures, such as elastomers, PTFE (Polytetrafluoroethylene), or metal-based materials.

Importance of High Pressure Shaft Seals

1. Leak Prevention One of the primary functions of high pressure shaft seals is to prevent leaks. In many industrial systems, the leakage of hydraulic fluid or gases can lead to significant operational inefficiencies and environmental concerns. A well-designed seal minimizes the risk of leakage, ensuring that the system operates smoothly and efficiently.

2. Protection Against Contaminants High pressure environments are often associated with significant amounts of dust, dirt, and other contaminants that can damage sensitive components. High pressure shaft seals act as a barrier, preventing these particles from entering the machinery and causing wear or failure over time.

high pressure shaft seals

3. Energy Efficiency Leaks can lead to energy loss, which is not only costly but also environmentally unfriendly. By effectively sealing rotating shafts, these seals help improve the overall energy efficiency of the system. A sealed system reduces the amount of energy required to maintain operational pressure, leading to lower energy costs.

4. Extended Equipment Lifespan The wear and tear caused by contaminants and leaks can lead to premature equipment failure. High pressure shaft seals contribute to extending the lifespan of machinery by minimizing wear on internal components. This reduction in wear translates to fewer maintenance needs and lower replacement costs over time.

5. Safety Considerations High-pressure systems often involve hazardous materials. Any leakage can pose a safety risk to personnel and the environment. High pressure shaft seals ensure that these materials remain contained within the system, reducing the risk of spills or accidents.

Challenges in High Pressure Sealing

Despite their advantages, high pressure shaft seals face several challenges. One of the main issues is the requirement for a perfect fit. If a seal is not properly installed or sized, it can fail, leading to leaks. Additionally, high pressure applications can cause wear and fatigue on seals over time. Therefore, selecting the right material and design is crucial for achieving optimal performance.

Conclusion

High pressure shaft seals are indispensable components in many industrial applications. They not only prevent leaks and protect against contaminants but also enhance energy efficiency and prolong the lifespan of machinery. As industries continue to advance and demands for efficiency increase, the importance of high pressure shaft seals cannot be overstated. Ensuring that these seals are properly designed, installed, and maintained will help companies achieve their operational goals while safeguarding the environment and enhancing workplace safety. Investing in quality high pressure shaft seals is an investment in the reliability and efficiency of industrial systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories