Dec . 12, 2024 00:42 Back to list

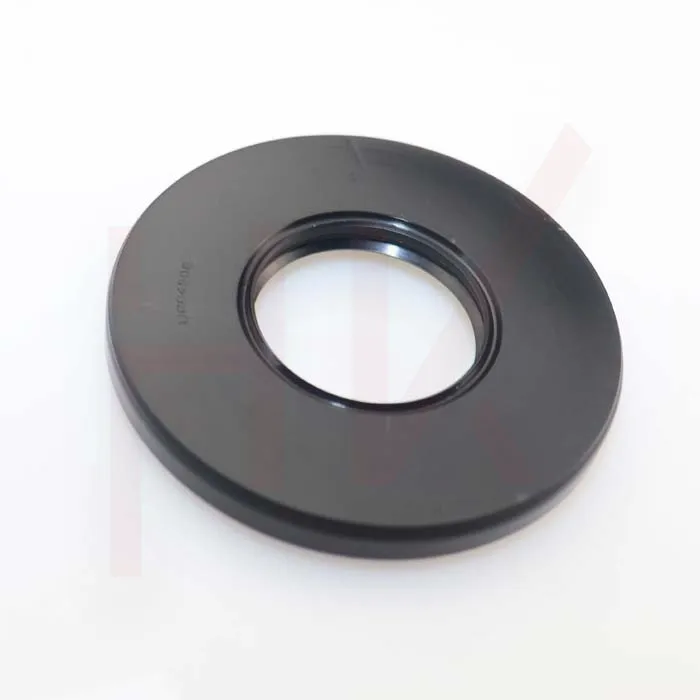

high pressure rotary shaft seals

High Pressure Rotary Shaft Seals An Essential Component for Industrial Applications

In the realm of mechanical engineering, high pressure rotary shaft seals play a critical role in ensuring the efficient operation of various machinery and equipment. These seals are designed to prevent the leakage of fluids while accommodating the rotational movement of shafts, a feature that is particularly vital in high-pressure environments. Understanding their importance, design, and applications can help enhance machinery performance and longevity.

The Function of Rotary Shaft Seals

Rotary shaft seals, sometimes referred to as oil seals or lip seals, serve a fundamental purpose to seal rotating shafts against the escape of fluids and the ingress of contaminants. They consist of a flexible sealing lip that makes contact with the rotating surface of the shaft. This contact creates a dynamic seal that can effectively withstand high pressures, making these seals indispensable in numerous industrial applications, including hydraulic systems, pumps, and automotive engines.

In high-pressure situations, where fluid leaking can lead to system failure or environmental hazard, the integrity of the rotary shaft seal is paramount. Proper sealing is essential to maintain system efficiency, reduce maintenance costs, and prolong equipment life. High pressure rotary shaft seals are engineered to endure the demands of extreme conditions, ensuring that the internal environments of machinery remain tightly sealed while allowing smooth operation.

Design Considerations

The design of high pressure rotary shaft seals is influenced by several factors including the type of fluid being contained (oil, water, chemicals), the pressure and temperature conditions, and the speed of the rotating shaft

. Modern seals are often constructed from advanced materials such as fluoropolymers, nitrile rubber, and silicone, which can withstand aggressive chemicals and high thermal stress.high pressure rotary shaft seals

Moreover, the geometry of the sealing lip is crucial. Different configurations, such as single-lip, double-lip, or even triple-lip designs, can provide additional barriers against leakage, especially in high-pressure applications. Designers must carefully balance the sealing lip's resilience and elasticity to maintain a reliable seal without excessive wear on the shaft surface.

Applications Across Industries

High pressure rotary shaft seals are widely used across various sectors. In the automotive industry, these seals are found in engines, transmissions, and drive axles, where they prevent the escape of lubricants and protect internal components from dirt and moisture. In hydraulic systems, they are critical for maintaining pressure and preventing fluid contamination, which can compromise system integrity and safety.

In industrial machinery, such as pumps and compressors, high pressure rotary shaft seals are essential for operational efficiency. Leakage in these systems can lead to significant energy losses, increased operational costs, and safety hazards. Thus, investing in high-quality rotary shaft seals can offer substantial economic benefits by reducing maintenance downtime and enhancing machinery performance.

Maintenance and Best Practices

To ensure the longevity and effectiveness of high pressure rotary shaft seals, regular inspection and maintenance are vital. Operators should monitor for any signs of wear, such as fluid leakage or excessive shaft wear. Implementing best practices, such as maintaining proper installation techniques, ensuring correct alignment of the shaft, and selecting the appropriate seal material for the operating environment, can significantly improve seal performance.

In conclusion, high pressure rotary shaft seals are a critical component in the machinery and equipment that power various industries. Their ability to prevent fluid leakage while enabling rotational movement makes them indispensable in high-pressure applications. By understanding their design, applications, and maintenance, engineers and operators can ensure the reliable performance of their systems, ultimately leading to enhanced productivity and reduced operational costs. As industrial demands continue to evolve, the development and innovation of rotary shaft seals will remain at the forefront of engineering solutions to meet the challenges of high-pressure environments.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories