Dec . 25, 2024 06:42 Back to list

high pressure rotary seal

High Pressure Rotary Seals An Essential Component in Modern Engineering

In various engineering applications, particularly in the fields of hydraulics and pneumatics, high pressure rotary seals play a crucial role. These seals are designed to prevent the leakage of fluids or gases while allowing rotational movement between two components. Their importance cannot be overstated, as they contribute significantly to the efficiency, safety, and longevity of machinery.

Understanding High Pressure Rotary Seals

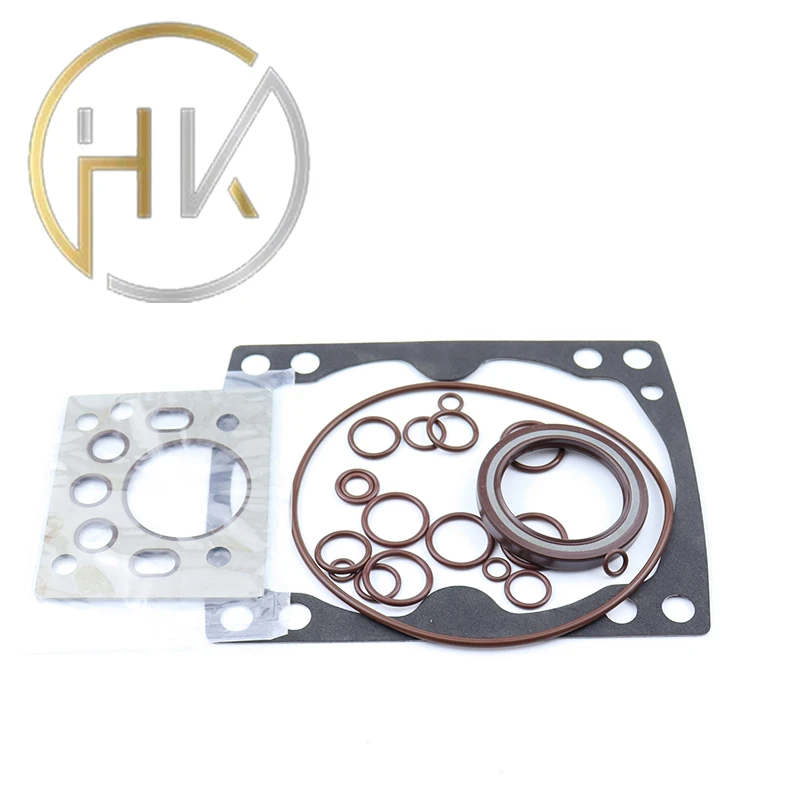

High pressure rotary seals are specialized components that allow for the rotation of one part relative to another while maintaining a sealed environment. They are widely used in systems where pressure levels can reach extremes—often exceeding several thousand psi (pounds per square inch). The design and materials used in these seals are crucial for their performance, as they need to withstand not only high pressures but also the friction generated by movement.

These seals typically consist of several parts including the sealing element, the housing, and sometimes additional components such as springs or backup rings. The sealing element may be made from elastomers, thermoplastics, or metal depending on the specific application and environmental conditions. Materials like fluorocarbon, nitrile rubber, and PTFE are commonly used due to their excellent resistance to oils, chemicals, and high temperatures.

Applications of High Pressure Rotary Seals

High pressure rotary seals find applications in a wide range of industries. In the automotive sector, they are used in power steering systems and fuel injection pumps where precise sealing is necessary to prevent leaks and ensure optimal performance. In the aerospace industry, they are critical for sealing moving parts in hydraulic systems and engines, where reliability and the ability to withstand extreme conditions are paramount.

Moreover, these seals are integral to various industrial processes, such as those found in oil and gas, mining, and manufacturing. In oil drilling operations, for example, rotary seals are used in blowout preventers, which are essential for managing high-pressure situations safely. Similarly, in manufacturing, they can be found in rotary machinery, such as mixers and pumps, where maintaining a sealed environment is critical to product quality and operational safety.

high pressure rotary seal

Challenges in Design and Implementation

While the benefits of high pressure rotary seals are significant, engineers face various challenges in their design and implementation. One of the primary challenges is ensuring that the seal remains effective over time, particularly under high stress and harsh environmental conditions. Factors such as temperature fluctuations, chemical exposure, and wear due to friction can all contribute to seal degradation.

To combat these issues, continuous advancements in materials science and engineering techniques are being made. For example, the development of advanced polymers with higher resilience to heat and wear has improved the performance of rotary seals. Additionally, computer simulations and modeling techniques are now being employed to better understand the behavior of seals in high-pressure environments, allowing for more tailored solutions.

Future Trends in High Pressure Rotary Seals

As technology advances, the future of high pressure rotary seals is also evolving. The trend toward greater automation in industrial processes means that the demand for reliable, high-performance seals will only continue to grow. Innovations such as smart seals equipped with sensors for monitoring wear or condition are emerging, paving the way for predictive maintenance and enhanced system reliability.

Furthermore, the push for sustainability in engineering practices is leading to the exploration of environmentally friendly materials for seal production. Biodegradable seal materials and designs that minimize waste and energy consumption during manufacturing are gaining attention in response to global environmental challenges.

Conclusion

High pressure rotary seals are a vital, yet often overlooked, component in modern engineering. Their ability to maintain a secure seal under extreme conditions makes them indispensable in many applications. Continuous advancements in materials and technology are likely to enhance their effectiveness further, ensuring that they remain a cornerstone of engineering solutions for years to come. As industries continue to evolve, the role of high pressure rotary seals will be critical in achieving safer, more efficient processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories