Nov . 27, 2024 19:30 Back to list

Durable Hydraulic Shaft Seals for High Pressure Applications in Industrial Settings

High Pressure Hydraulic Shaft Seals An Overview

High pressure hydraulic shaft seals are critical components in various hydraulic systems, responsible for preventing fluid leakage and ensuring the efficient operation of machinery. These seals are designed to withstand extreme pressures, making them essential in applications ranging from industrial equipment to automotive systems. This article delves into the importance, types, applications, and selection criteria of high pressure hydraulic shaft seals.

Importance of Hydraulic Shaft Seals

In hydraulic systems, the main function of seals is to contain hydraulic fluid within designated areas, maintaining pressure and preventing contamination. A high pressure hydraulic seal is particularly vital because it protects both the environment and the equipment. When seals fail, they can lead to fluid leaks, which not only waste valuable resources but also pose safety hazards. Moreover, leakage can cause damage to components, resulting in increased maintenance costs and downtime.

Types of High Pressure Hydraulic Shaft Seals

Hydraulic shaft seals come in various designs, each suited to specific applications and operating conditions. The most common types include

1. O-Rings O-rings are circular seals made from elastomeric materials and are used in applications where low friction and reliable sealing are necessary. They are the simplest form of sealing and can effectively handle moderate pressure levels.

2. U-Cups These seals have a U-shaped cross-section, providing a better sealing solution for dynamic applications. U-cups can handle higher pressures compared to O-rings and are ideal for rod and piston seals in hydraulic cylinders.

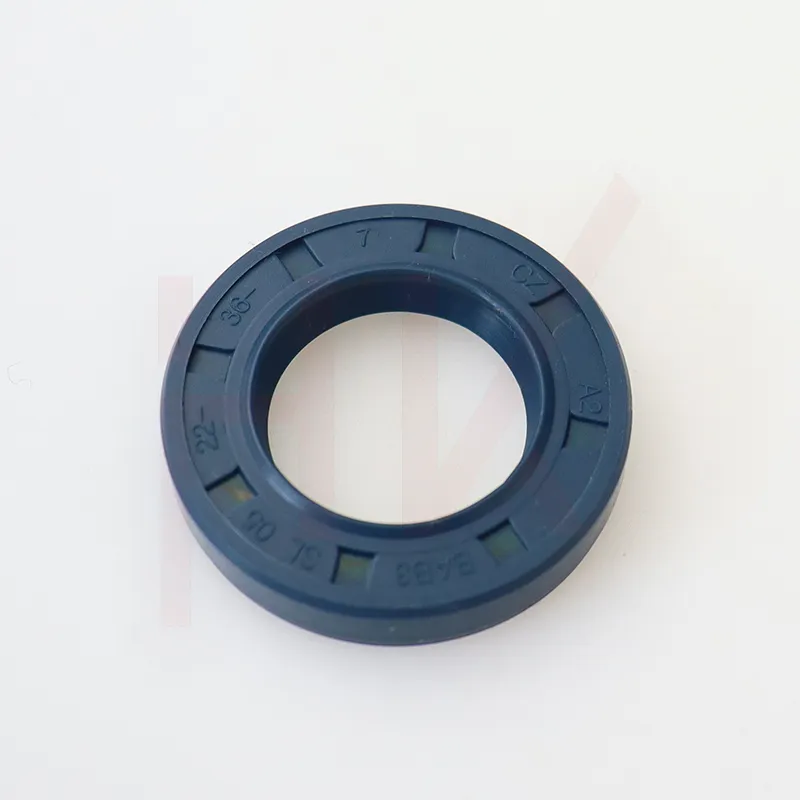

3. Lip Seals This type of seal consists of a flexible lip that presses against the shaft, providing a reliable seal against hydraulic fluids. They are often used where there is a need for axial movements and are effective at high pressures.

4. PTFE Seals Polytetrafluoroethylene (PTFE) seals are known for their excellent chemical resistance and ability to operate at high temperatures. They offer low friction and are suitable for high-speed applications under extreme pressure conditions.

5. Composite Seals These seals combine materials such as rubber and thermoplastics, providing enhanced performance characteristics. They are designed to withstand high pressures and are often used in heavy-duty applications.

Applications of High Pressure Hydraulic Shaft Seals

High pressure hydraulic shaft seals are utilized in numerous industries, including

high pressure hydraulic shaft seals

- Oil and Gas In drilling and extraction equipment, these seals ensure the integrity of hydraulic systems that operate under extreme pressures. - Automotive Hydraulic systems in vehicles, such as brakes and power steering, rely on high pressure seals to maintain fluid containment and performance.

- Manufacturing Equipment such as hydraulic presses and injection molding machines depend significantly on reliable sealing solutions to function efficiently.

- Aerospace Hydraulic systems in aircraft require exceptionally reliable sealing components that can withstand not only high pressures but also significant variations in temperature and exposure to chemicals.

Considerations for Selecting High Pressure Hydraulic Shaft Seals

Choosing the right hydraulic seal is crucial for the longevity and efficiency of the machinery. Here are some factors to consider during selection

1. Pressure Rating Ensure that the seal can handle the maximum pressure encountered in the application.

2. Temperature Range The material of the seal should withstand the temperature fluctuations of the hydraulic fluid and the operating environment.

3. Fluid Compatibility The seal material must be compatible with the hydraulic fluid to prevent degradation over time.

4. Speed In dynamic applications, consider the operating speed; certain seal types perform better at high speeds than others.

5. Installation and Maintenance Look for seals that are easy to install and maintain, reducing downtime and maintenance costs.

Conclusion

High pressure hydraulic shaft seals play a pivotal role in the effectiveness and safety of hydraulic systems across various applications. With diverse types available, it’s essential to choose the right seal based on application requirements. Proper seal selection not only enhances performance but also extends the life of the equipment, ultimately leading to significant cost savings and operational efficiency. As technology advances, the demand for more reliable and efficient sealing solutions will continue to grow, underscoring the importance of these components in modern machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories