Sep . 08, 2024 21:02 Back to list

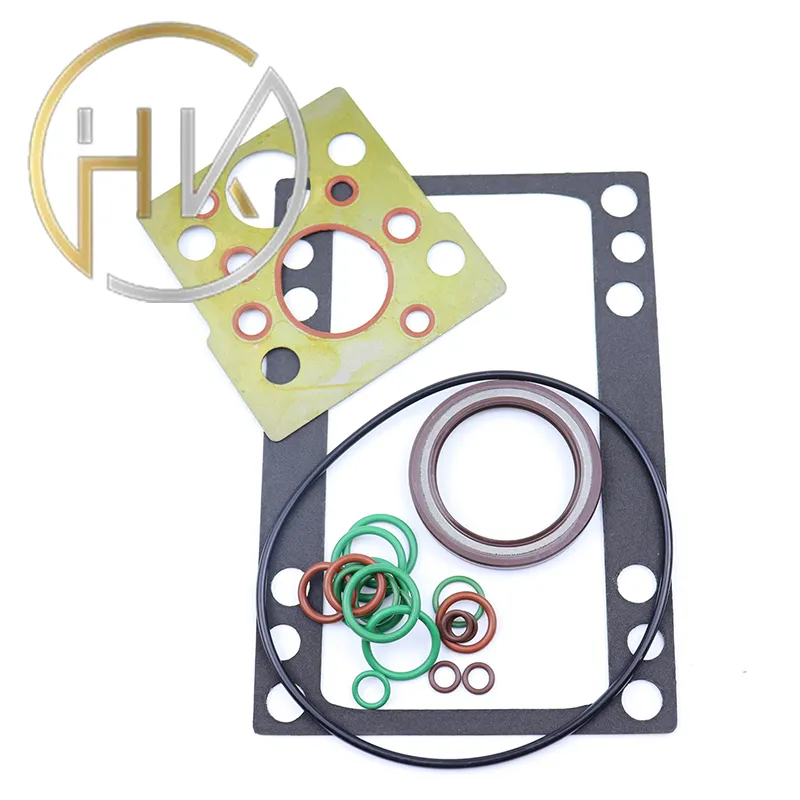

high temp oil seal

High Temperature Oil Seals A Vital Component in Machinery

In the realm of mechanical engineering, high temperature oil seals play a crucial role in ensuring the efficient operation and longevity of machinery. As industrial processes often involve challenging environments, the need for reliable sealing solutions becomes paramount. High temperature oil seals are specifically designed to withstand extreme conditions, making them essential in various applications from automotive engines to heavy industrial equipment.

High Temperature Oil Seals A Vital Component in Machinery

One of the key features of high temperature oil seals is their ability to handle not only temperature extremes but also chemical exposure. In various industries, including automotive, aerospace, and manufacturing, the fluids involved may contain additives or other chemicals that can compromise standard seals. High temperature oil seals are engineered to resist these adverse effects, providing a robust barrier against both heat and chemical degradation.

high temp oil seal

The benefits of using high temperature oil seals extend beyond just preventing leaks. By maintaining proper fluid retention, these seals contribute to the overall efficiency of machinery. Smooth operation reduces friction and energy consumption, which is essential in energy-intensive applications. Moreover, by protecting internal components from contamination, high temperature oil seals help prolong the service life of equipment, reducing maintenance costs and downtime.

When selecting a high temperature oil seal, several factors must be considered. These include the maximum operating temperature, the type of fluid being sealed, and the specific machinery application. Proper selection is crucial for achieving optimal performance and reliability. Manufacturers often provide detailed specifications and guidelines for choosing the right seal, ensuring that end-users can make informed decisions.

In conclusion, high temperature oil seals are indispensable in various mechanical systems. Their ability to withstand extreme temperatures and resist chemical degradation makes them a vital component in protecting machinery and enhancing operational efficiency. As industries continue to evolve and face new challenges, the importance of high performance sealing solutions will only grow, underscoring the need for ongoing innovation in seal technology. Whether in automotive engineering or industrial applications, high temperature oil seals remain a cornerstone of reliable machinery design.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories