Aug . 15, 2024 09:35 Back to list

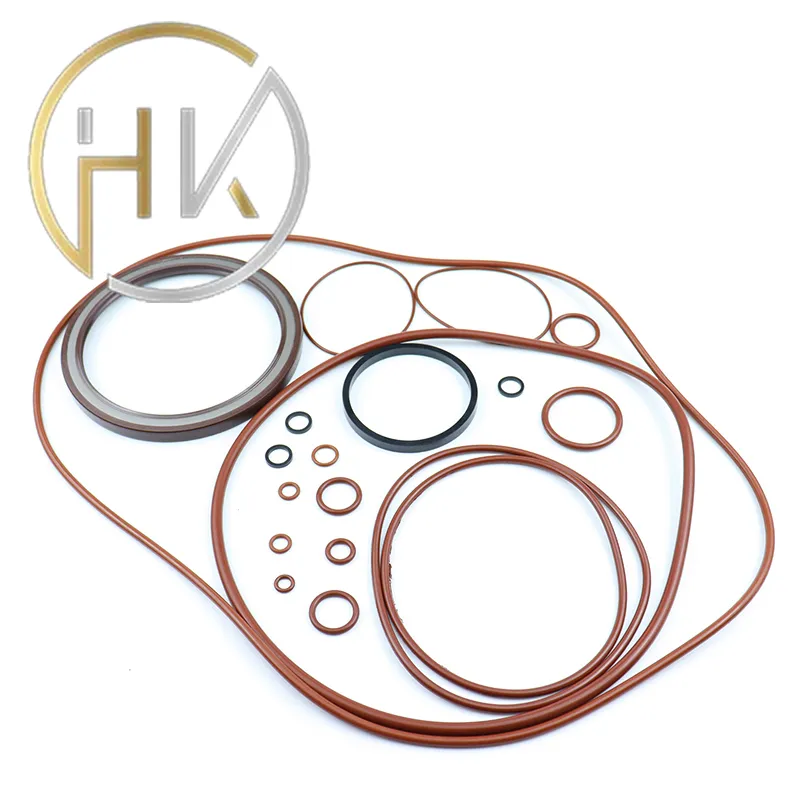

High-Quality Seal Kit for 3-Inch Hydraulic Cylinders Designed for Optimal Performance and Longevity

Understanding 3-Inch Hydraulic Cylinder Seal Kits

Hydraulic systems are essential in various industrial and mechanical applications, offering effective force multiplication and movement management. Among the key components that ensure their longevity and efficiency are seal kits. The 3-inch hydraulic cylinder seal kit, in particular, plays a crucial role in maintaining the performance and durability of hydraulic cylinders. This article will explore the significance, components, and maintenance aspects of these seal kits.

What is a Hydraulic Cylinder Seal Kit?

A hydraulic cylinder seal kit comprises various seals and components designed to prevent fluid leakage from hydraulic cylinders while ensuring smooth operation. These kits are essential for maintaining the integrity of the hydraulic system, as any loss of hydraulic fluid can lead to reduced efficiency, potential damage, and costly repairs. The 3-inch designation refers to the diameter of the hydraulic cylinder, making it a commonly used size in many machinery applications.

Components of a 3-Inch Hydraulic Cylinder Seal Kit

A typical 3-inch hydraulic cylinder seal kit includes several key components designed to address various sealing needs

1. O-Rings These are circular seals that fit into grooves within the cylinder or rod, providing a tight seal to prevent fluid leakage. O-rings are vital for dynamic sealing applications, particularly where motion occurs.

2. Rod Seals Also known as piston seals, these create a barrier between the moving piston and the cylinder wall. They ensure that the hydraulic fluid is contained within the cylinder, enabling efficient movement and force generation.

3. Back-Up Rings These are used in conjunction with O-rings to provide additional support and prevent extrusion of the seals under high pressure. They enhance the reliability and lifespan of the seals.

4. Dust Seals These seals are positioned at the outer edge of the cylinder, protecting the internal components from dirt, debris, and moisture. Dust seals are crucial for maintaining operational integrity, especially in outdoor applications.

3 inch hydraulic cylinder seal kit

Importance of Using Quality Seal Kits

Using high-quality seal kits is essential for the reliability of hydraulic systems. Poor-quality seals may result in premature wear, leading to leaks and decreased performance. Investing in durable and reliable components ensures longer maintenance intervals, reduced downtime, and overall cost savings in operational expenses. Additionally, manufacturers often guarantee their products, providing peace of mind regarding quality and performance.

Maintenance Tips for Hydraulic Cylinder Seal Kits

To maximize the lifespan of a 3-inch hydraulic cylinder seal kit, regular maintenance is crucial. Here are some tips

1. Inspect Regularly Periodically check for signs of wear or damage. Look for leaks, which may indicate that the seals have degraded.

2. Clean the Cylinder Keep the hydraulic cylinder clean to prevent dirt and debris from damaging the seals. Use appropriate cleaning solutions that are compatible with hydraulic fluid.

3. Check Fluid Levels Maintaining the correct hydraulic fluid levels helps ensure optimal performance and reduces strain on the seals.

4. Replace as Needed If wear or damage is detected, replace the seals promptly to avoid more severe damage to the hydraulic system.

5. Consider Environmental Factors If the equipment operates in harsh environments, consider using seals made from materials that can withstand extreme temperatures, pressures, and exposure to chemicals.

Conclusion

The 3-inch hydraulic cylinder seal kit is a vital component in the operation and maintenance of hydraulic systems. Understanding its components and the importance of using high-quality materials can contribute to the efficiency and longevity of hydraulic equipment. By prioritizing regular maintenance and inspections, operators can ensure optimal performance, minimizing the risk of leaks and costly repairs. Investing in reliable seal kits is not just a purchase; it’s an investment in the future efficiency of hydraulic operations.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories