Aug . 15, 2024 10:47 Back to list

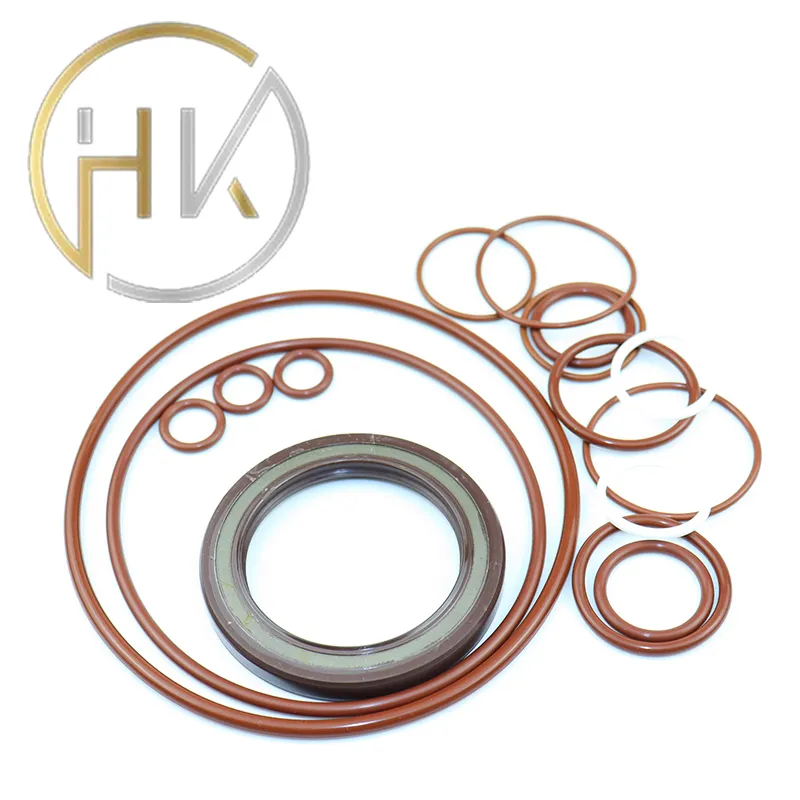

High-Quality 12x22x7 Oil Seal for Reliable Performance in Various Applications

Understanding the 12x22x7 Oil Seal Importance and Applications

Oil seals play a crucial role in various mechanical applications, ensuring the longevity and efficiency of machinery. Among the myriad of oil seals available in the market, the 12x22x7 oil seal stands out due to its specific dimensions and versatile applications. This article aims to provide an in-depth look at this particular oil seal, its significance, and the types of applications where it is most commonly used.

What is an Oil Seal?

An oil seal, often referred to as a shaft seal, is a device designed to seal the space between the rotating shaft and the stationary parts of machinery. Its primary function is to prevent the leakage of lubricants, such as oil or grease, while simultaneously blocking contaminants from entering the system. The integrity of this seal is essential for maintaining optimal performance in various machinery, including automotive, industrial, and agricultural equipment.

Specifications of the 12x22x7 Oil Seal

The designation ‘12x22x7’ refers to the dimensions of the oil seal in millimeters a 12 mm inner diameter, a 22 mm outer diameter, and a 7 mm width. These specific measurements make the 12x22x7 oil seal an essential component in several devices and machines. The design usually features a rubber or elastomeric material with a metal casing to provide strength and durability, ensuring it can withstand the pressures and temperatures typical in industrial applications.

Importance of the 12x22x7 Oil Seal

1. Leak Prevention The primary function of the 12x22x7 oil seal is to prevent oil leakage from rotating shafts. This is crucial in maintaining the lubricating properties of the oil, which in turn affects the performance and longevity of the machinery.

2. Contaminant Protection In environments exposed to dust, dirt, and other pollutants, oil seals act as barriers, preventing these contaminants from entering the lubrication system. This protection is vital for machinery that operates in harsh conditions.

12x22x7 oil seal

3. Efficiency Maintenance By preventing both oil leaks and the ingress of contaminants, the oil seal contributes to the overall efficiency of mechanical systems. Properly sealed units require less maintenance and provide better performance over time.

Applications of the 12x22x7 Oil Seal

The versatility of the 12x22x7 oil seal makes it suitable for various applications. Some of the most common uses include

1. Automotive Industry This oil seal is frequently used in vehicles for engine components, transmission systems, and differentials. Its reliable sealing ensures that vehicles maintain optimal performance and efficiency.

2. Industrial Equipment In manufacturing and industrial settings, the 12x22x7 oil seal is found in pumps, gearboxes, and motors, helping to maintain the integrity of these critical systems.

3. Agricultural Machinery Equipment such as tractors and harvesters often employ this oil seal to protect against the harsh conditions typical in farming environments, enhancing durability and performance.

Conclusion

The 12x22x7 oil seal is a simple yet crucial component in many mechanical systems. By preventing oil leakage and protecting against contaminants, it helps maintain the efficiency and longevity of various machines. Understanding the significance of such components can aid in better maintenance practices, ultimately leading to enhanced performance and reduced operational costs. Whether in automotive, industrial, or agricultural applications, the importance of reliable oil seals cannot be overstated.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories