Aug . 10, 2024 11:05 Back to list

High Pressure Oil Seal Solutions for Enhanced Performance and Durability in Industrial Applications

Understanding High Pressure Oil Seals Importance, Types, and Applications

Oil seals, often referred to as radial lip seals or simply seals, are essential components in various mechanical systems, especially in devices that involve the containment of fluids. When it comes to high-pressure applications, these seals play a pivotal role in ensuring the efficient operation and longevity of equipment. In this article, we will delve into the significance, types, and applications of high-pressure oil seals.

Importance of High-Pressure Oil Seals

High-pressure oil seals are designed to withstand substantial pressure without compromising their integrity. They are critical in preventing leaks of oil and other lubricants, which can lead to significant mechanical failures, reduced efficiency, and increased maintenance costs. The ability of a seal to maintain a tight fit under high pressure ensures that lubricants remain within the system, providing optimal lubrication to moving parts. This ultimately extends the life of machinery and helps in maintaining operational efficiency.

Moreover, high-pressure oil seals also contribute to reducing contamination. In many applications, external contaminants can lead to premature wear and tear of components. By effectively sealing the assembly, these oil seals prevent dirt, dust, and other particles from entering the system, thereby protecting the integrity of the lubricants and the machinery involved.

Types of High-Pressure Oil Seals

There are several types of high-pressure oil seals, each designed for specific applications and conditions. Some of the most common types include

1. Single Lip Oil Seals These are used in various applications and are effective in retaining lubricants while preventing external contaminants. They typically consist of a rubber outer part that forms a tight seal against the housing.

2. Double Lip Oil Seals Featuring two sealing lips, these seals provide enhanced protection against both internal leakage and external contamination. They are particularly useful in applications where both lubrication and protection are critical.

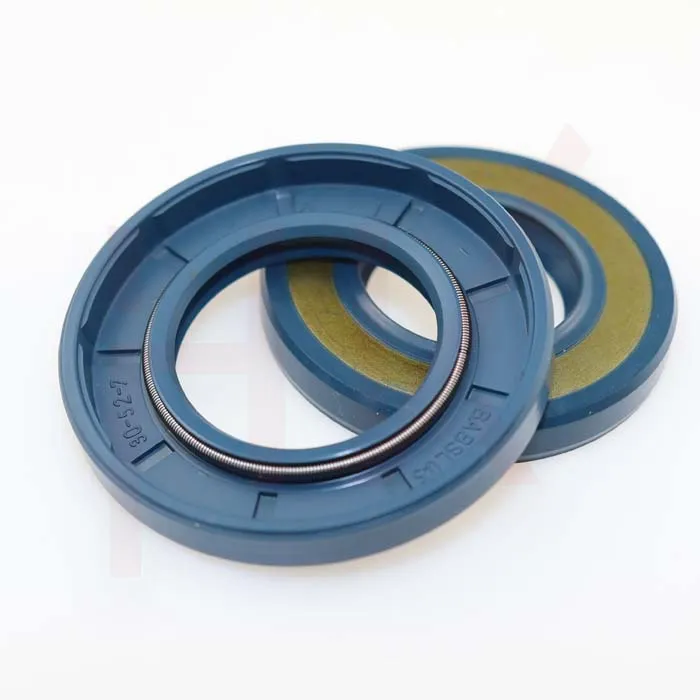

3. Spring-Loaded Oil Seals These seals incorporate a spring that applies pressure to the sealing lip, ensuring better contact with the shaft. This is especially important in high-pressure scenarios, as it enhances sealing performance and helps manage wear.

oil seal high pressure

4. PTFE Seals Polytetrafluoroethylene (PTFE) oil seals are known for their chemical resistance and low friction. They are often used in high-pressure and high-temperature applications, making them ideal for specialized machinery in industries such as aerospace and automotive.

Applications of High-Pressure Oil Seals

High-pressure oil seals are utilized across various industries, including

- Automotive In engines and transmissions, oil seals are crucial for maintaining oil pressure and preventing leaks that could result in engine failure.

- Manufacturing Machinery such as hydraulic presses and pumps often operate under high pressure, necessitating reliable seals to ensure performance and safety.

- Aerospace The unique demands of aerospace applications require seals that can withstand extreme conditions. High-pressure oil seals help maintain the performance of critical systems like landing gear and fuel systems.

- Oil and Gas In drilling and pumping equipment, high-pressure oil seals are vital for managing the pressures encountered in extraction processes and ensuring safety and efficiency.

Conclusion

High-pressure oil seals are indispensable elements in modern machinery and equipment. Their ability to maintain the integrity of fluid systems under challenging conditions is critical for the operational effectiveness of various industries. By understanding the types and applications of these seals, engineers and maintenance professionals can make informed decisions to improve performance, reduce operational costs, and enhance the longevity of their machinery. As technology progresses, the development of advanced materials and sealing methods will likely further enhance the function and reliability of high-pressure oil seals in the future.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories