Aug . 14, 2024 06:46 Back to list

High-Performance Boom Cylinder Seal Kits for Enhanced Hydraulics and Improved Equipment Longevity

Understanding the Importance of Boom Cylinder Seal Kits

In the world of hydraulic systems, performance and reliability are paramount. One critical component that often gets overlooked but plays a pivotal role in ensuring optimal functionality is the boom cylinder seal kit. This article explores the significance of boom cylinder seal kits, their components, maintenance, and the consequences of neglecting them.

What is a Boom Cylinder Seal Kit?

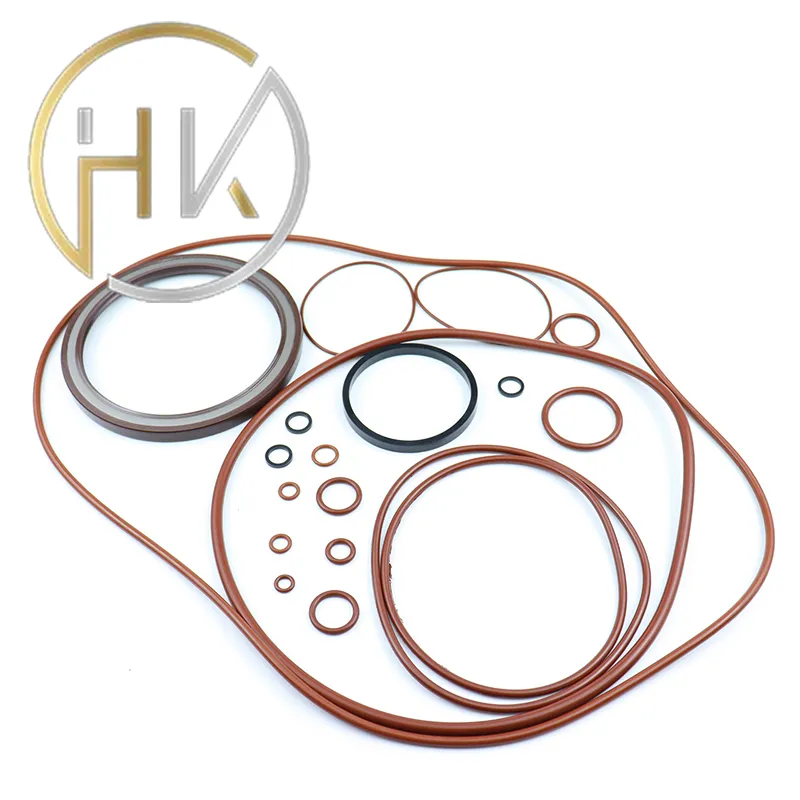

A boom cylinder is a type of hydraulic cylinder that is often found in construction equipment, such as excavators and cranes, which enables vertical movement of the boom. The sealing elements within this cylinder are essential for maintaining pressure and preventing hydraulic fluid from leaking out. A boom cylinder seal kit typically includes various seals, O-rings, and backup rings explicitly designed to fit specific boom cylinder models.

Components of a Seal Kit

The seal kit consists of several components, each serving a unique function

1. Seals These are the primary components responsible for preventing fluid leaks. They come in various shapes and materials, including polyurethane, rubber, and silicone, to withstand different pressures and temperatures.

2. O-Rings These circular seals fit in grooves to create a tight seal under compression. While they might seem simple, they are integral to ensuring leak-free operations.

3. Backup Rings Used alongside O-rings, these rings prevent extrusion of the O-ring under high pressure, lengthening the lifespan of the sealing elements.

boom cylinder seal kit

4. Dust Seals Designed to keep contaminants like dirt and debris out of the hydraulic system, these seals help protect the integrity of the seals and prolong the life of the boom cylinder.

Maintenance and Replacement

The longevity and efficiency of boom cylinder seal kits are heavily reliant on regular maintenance. In hydraulic systems, the buildup of heat and pressure can lead to wear and tear on seal components. Regular inspections can help identify signs of leakage, such as oil or fluid accumulation around the cylinder, which may indicate that it is time to replace the seal kit.

Adhering to a maintenance schedule is vital. Operators should routinely check for signs of wear, especially after heavy use, and clean the exterior of the boom cylinder to prevent contaminants from entering the system. Implementing these practices not only aids in early detection of issues but also ensures that the hydraulic system operates at peak efficiency.

Consequences of Neglect

Neglecting the maintenance and timely replacement of boom cylinder seal kits can lead to severe complications. Fluid leaks not only decrease efficiency but can also pose safety hazards on job sites. A hydraulic system that operates with low fluid levels due to leaks can lead to catastrophic failures, potentially causing accidents, equipment damage, and even injuries.

Additionally, the cost implications of neglecting seal kit maintenance can be significant. Frequent repairs or replacements of the entire boom cylinder due to extensive damage incurred from a simple seal failure can lead to downtime and increased operational costs.

Conclusion

Boom cylinder seal kits are a small but vital part of hydraulic systems in the construction and manufacturing industries. Regular maintenance and timely replacement of these kits can save businesses considerable costs and enhance the safety and efficiency of equipment operation. Understanding the components, conducting routine inspections, and acting promptly at the first sign of wear will help ensure the longevity and functionality of boom cylinders. Investing attention and resources into these seal kits is not just a matter of equipment maintenance; it is also a commitment to operational excellence and safety in the workplace.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories