Dec . 21, 2024 14:32 Back to list

gland seal kit

Understanding Gland Seal Kits Importance and Applications

Gland seal kits play a crucial role in various industrial applications, serving as an essential component in the maintenance of machinery and equipment. These kits are designed to prevent leaks in systems that involve fluids, gases, or other substances, ensuring efficiency, safety, and reliability in operation. In this article, we will delve into the importance, components, and applications of gland seal kits, shedding light on their relevance across different sectors.

What is a Gland Seal Kit?

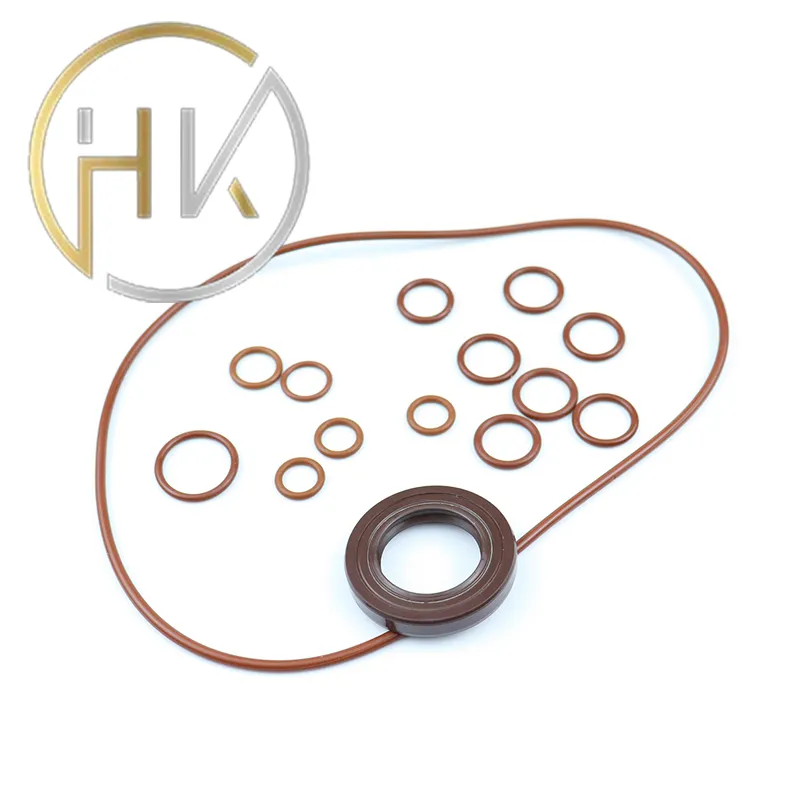

A gland seal kit typically comprises a collection of sealing materials and components designed specifically for use in gland assemblies. These seals often include O-rings, packing, gaskets, and other specialized seals. The primary function of these kits is to create a barrier that prevents the escape of fluids or gases from the machinery, thus maintaining pressure and preventing contamination that could lead to failure or hazards.

Importance of Gland Seal Kits

1. Leak Prevention The primary purpose of gland seal kits is to prevent leaks in mechanical systems. Leaks can lead to significant losses in materials, which not only increases operational costs but can also pose serious safety hazards.

2. System Integrity Maintaining the integrity of systems is vital for optimal performance. Gland seal kits ensure that machinery operates within its intended parameters, preventing issues that can arise from pressure drops or contamination.

3. Maintenance and Longevity Regular maintenance of gland seals prolongs the life of machinery. Gland seal kits make it easier to replace worn-out seals, ensuring that equipment continues to function efficiently and that downtime is minimized.

4. Safety In industries where hazardous materials are involved, gland seal kits are critical for ensuring the safety of workers and the environment. By effectively containing substances, they reduce the risk of spills and leaks that could lead to accidents.

Components of Gland Seal Kits

A typical gland seal kit may contain several components, each serving a specific function

- O-Rings These circular seals provide a tight fit around shafts and other components, preventing fluid leakage.

- Packing This material can be made from various substances including graphite, PTFE, or rubber, and is used to fill spaces between equipment parts.

gland seal kit

- Gaskets These are flat seals that are used between two surfaces to prevent leakage. They come in various materials depending on the application requirements.

- Backup Rings These are used alongside O-rings to prevent extrusion and assist in pressure management.

Each component is carefully engineered to withstand specific temperatures, pressures, and chemical environments, making selection based on application critical.

Applications of Gland Seal Kits

Gland seal kits are utilized in a myriad of industries, underlining their versatility. Some key applications include

1. Pumps In pumping systems, gland seals are crucial for preventing leaks at the pump shaft, which could lead to significant inefficiencies and unsafe working conditions.

2. Compressors In air and gas compressors, gland seal kits help maintain pressure stability and prevent the escape of compressed gases.

3. Hydraulic Systems Hydraulic machines rely on effective sealing to maintain pressure and minimize the risk of fluid leaks, which can be detrimental to performance.

4. Manufacturing Equipment In various manufacturing processes, gland seal kits help ensure that equipment functions correctly by preventing contamination and maintaining operating conditions.

5. Marine and Aerospace Applications These sectors require highly reliable sealing to manage pressures and prevent leaks in critical systems.

Conclusion

In summary, gland seal kits are indispensable in modern industrial operations, playing a vital role in ensuring safety, efficiency, and longevity of machinery. As technologies evolve, so do the materials and designs of these kits, reflecting the need for greater performance in increasingly demanding applications. Proper selection, installation, and maintenance of gland seal kits can lead to enhanced operational efficiency, reduced environmental impact, and improved safety standards across various industries. Understanding their significance and proper application is crucial for anyone involved in machinery maintenance and operation, highlighting the profound influence of these small but essential components on industrial effectiveness.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories