Dec . 04, 2024 09:13 Back to list

gland seal kit

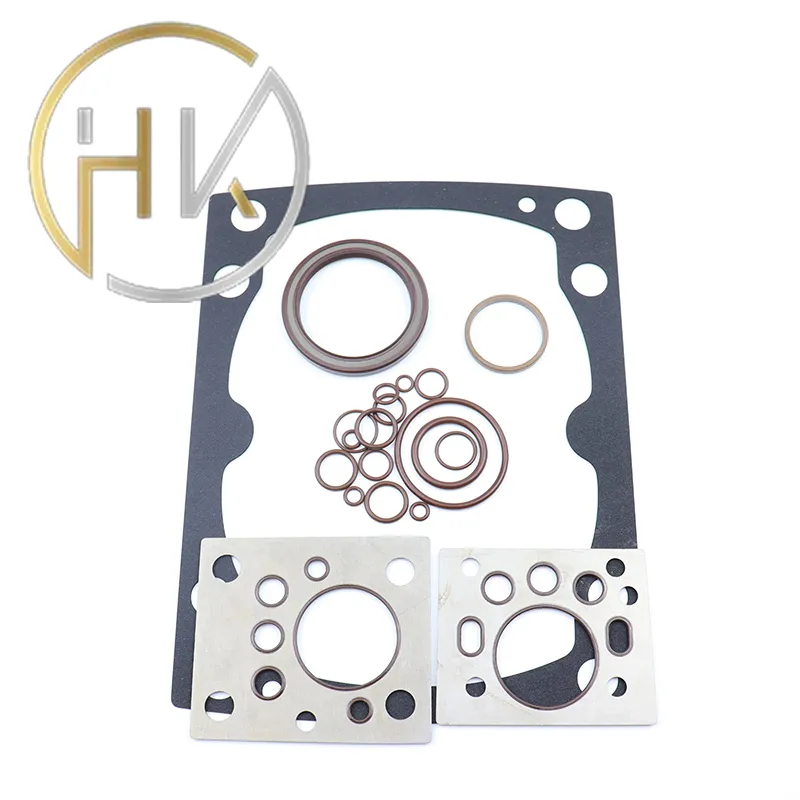

Understanding Gland Seal Kits A Comprehensive Overview

Gland seal kits are an integral component in various industrial machinery, particularly in applications involving rotating equipment such as pumps, compressors, and turbines. These kits play a crucial role in preventing leakage of fluids and maintaining the efficiency of machinery. The function of gland seal kits is to create a tight seal around the moving parts, ensuring that operational fluids remain contained and that contaminants do not enter the system.

What is a Gland Seal Kit?

Essentially, a gland seal kit consists of various components designed to work together to provide a reliable sealing solution. Typically, these kits include sealing rings, packing materials, and sometimes additional components like O-rings or bushings. The primary purpose is to surround the shaft where it exits the housing, forming a barrier that keeps lubricants and coolants in while keeping dust, dirt, and other contaminants out.

Importance of Gland Seal Kits

The significance of gland seal kits cannot be overstated. In many industrial scenarios, maintaining the integrity of fluids is crucial for both operational efficiency and safety. Fluid leaks not only pose environmental hazards but can also lead to costly downtime and repairs. An effective gland seal kit ensures that the machinery operates smoothly by preventing fluid loss and maintaining pressure, which is especially critical in high-temperature and high-pressure environments.

Components of Gland Seal Kits

A typical gland seal kit may include the following components

1. Sealing Rings These are made from materials that can withstand the operating conditions of the machinery, including temperature and pressure variations. Common materials include rubber, PTFE (polytetrafluoroethylene), and graphite.

gland seal kit

2. Packing Materials Often made from natural or synthetic fibers, packing materials are used to fill the space around the shaft and compress against it when the gland is tightened, enhancing the seal’s effectiveness.

3. Casing or Gland Housing This holds the sealing and packing components in place and applies the necessary pressure to create a tight seal.

4. Miscellaneous Hardware Depending on the specific application, kits may include various fasteners, adjusters, or jacking screws that facilitate installation and maintenance.

Choosing the Right Gland Seal Kit

Selecting the right gland seal kit involves assessing several factors, including the type of machinery, the nature of the fluids involved, and operating conditions such as temperature and pressure. It’s also essential to consider the frequency of maintenance required and the environments in which the machinery operates, as these factors can greatly influence seal durability.

Maintenance and Replacement

Regular maintenance is critical to ensuring the longevity of gland seal kits. This includes inspection for wear and tear, proper lubrication, and replacing worn-out components. Over time, seals can degrade due to continuous exposure to heat and pressure, leading to inefficiencies and potential failures. Therefore, having a tailored maintenance schedule can prolong the life of the seal and the equipment it protects.

Conclusion

In conclusion, gland seal kits are vital for ensuring the efficient operation of machinery across various industries. By preventing leaks and protecting against contaminants, these kits contribute to both operational efficiency and equipment longevity. Understanding the components and maintenance of gland seal kits is essential for any professional involved in machinery operation and maintenance. As industries continue to evolve and demand more from their equipment, the importance of reliable sealing solutions will only grow, underscoring the need for high-quality gland seal kits and proactive maintenance strategies.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories