Nov . 28, 2024 01:27 Back to list

Choosing the Right Gearbox Oil Seal for Optimal Performance and Longevity

Understanding Gearbox Oil Seals Importance and Maintenance

Gearbox oil seals play a vital role in the longevity and efficiency of automotive gearboxes. These seals prevent lubricating oil from leaking out while simultaneously keeping unwanted contaminants from entering the gearbox, thus ensuring optimal performance and longevity of the transmission system. Understanding their function, types, and maintenance can help car owners and mechanics alike maintain vehicle performance and extend the lifespan of gearboxes.

What is a Gearbox Oil Seal?

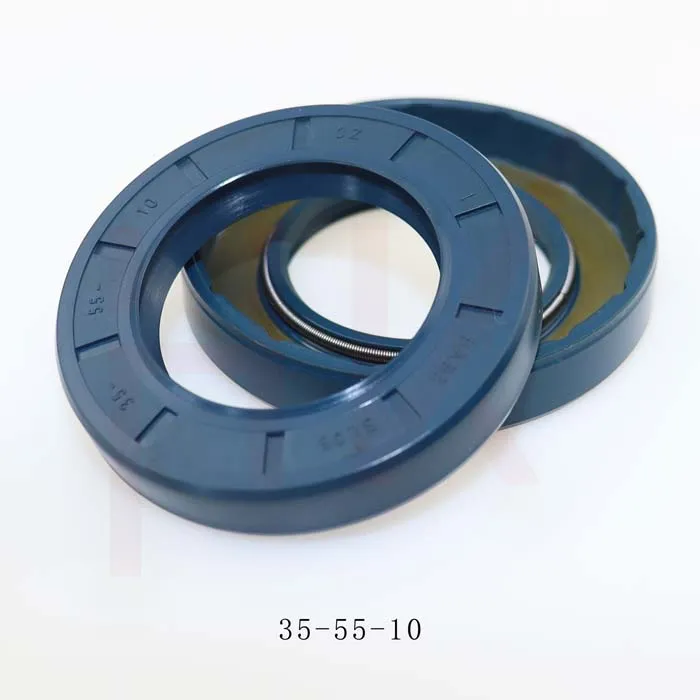

A gearbox oil seal is a sealing device that is placed between the components of a gearbox to prevent oil leaks. It is typically made from materials like rubber or silicone, which provide a flexible yet durable barrier. The seals are designed to operate under high pressure and varying temperatures while maintaining a tight closure around rotating shafts. This mechanism is essential for the efficient operation of both manual and automatic transmissions.

Types of Gearbox Oil Seals

There are several types of gearbox oil seals, each designed to meet different requirements based on the gearbox design and application. The most common types include

1. Rotary Oil Seals Also known as lip seals, rotary oil seals are designed to sit around rotating shafts. They consist of a flexible lip that presses against the shaft, effectively sealing in the oil while preventing dust and dirt from entering.

2. Static Oil Seals Unlike rotary seals, static oil seals are designed for applications where there is no movement. These seals are used to seal joints between stationary components.

3. Double-lip Seals These seals have two sealing lips, providing enhanced protection against oil leakage and contamination. Double-lip seals are commonly used in high-performance applications where higher pressures and speeds are involved.

Importance of Gearbox Oil Seals

The integrity of gearbox oil seals is crucial for several reasons

- Leak Prevention The primary function of oil seals is to prevent fluid leaks, which can lead to low oil levels and increased wear on moving parts. Low oil levels can result in overheating and ultimately lead to gearbox failure.

- Contaminant Defense Oil seals act as barriers against contaminants such as dirt, dust, and moisture. If contaminants penetrate the gearbox, they can cause severe damage, leading to costly repairs.

gear box oil seal

- Operational Efficiency Properly functioning oil seals ensure that the gearbox operates smoothly, promoting efficiency and performance. This is particularly important in high-demand applications, such as racing or heavy towing.

Signs of a Failing Oil Seal

Recognizing the signs of a failing gearbox oil seal can help prevent serious damage. Common symptoms include

- Oil Leakage Puddles of oil beneath the vehicle can indicate a leaking oil seal. This is often the most visible sign of seal failure.

- Unusual Noises Grinding or whining noises coming from the gearbox can signal that the internal components are no longer adequately lubricated due to oil seepage.

- Overheating A decrease in oil levels can lead to higher operating temperatures within the gearbox, which may manifest as overheating during operation.

Maintenance and Replacement

Maintaining gearbox oil seals involves regular inspections and timely replacements. This includes

- Regular Inspections Regularly checking for signs of oil leakage or dirt around the seals can help catch problems early.

- Fluid Changes Following the manufacturer’s recommendations for fluid changes will help ensure that the seals are not exposed to degraded oil, which can lead to quicker wear.

- Professional Assistance If oil seal failure is detected, it is advisable to seek professional help. Replacing oil seals can be complicated and may require specialized knowledge and tools.

Conclusion

Gearbox oil seals are essential components in vehicle transmission systems, providing critical protection against oil leaks and contamination. Understanding their function, types, and maintenance routines empowers vehicle owners and mechanics to ensure the reliability and efficiency of gearboxes. By paying attention to the signs of oil seal failure and conducting regular maintenance, one can significantly prolong the life of the gearbox and maintain the vehicle’s overall performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories