Oct . 17, 2024 10:04 Back to list

front wheel bearing seal

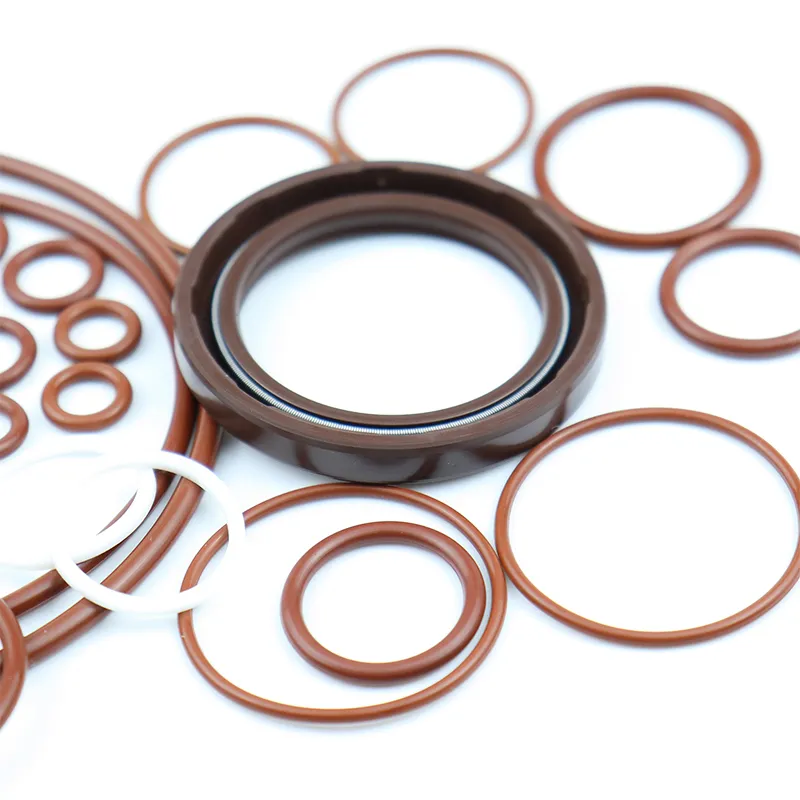

Understanding Front Wheel Bearing Seals

Front wheel bearing seals are critical components in automotive engineering that often go unnoticed until a significant issue arises. These seals play a crucial role in protecting the wheel bearings from contaminants and ensuring proper lubrication. The function of the front wheel bearing seal is to prevent dirt, moisture, and other harmful materials from entering the bearing assembly while retaining the necessary lubricant within. Understanding the importance and maintenance of these seals can help improve vehicle performance and longevity.

Function of Front Wheel Bearing Seals

Front wheel bearing seals serve a vital purpose in vehicle operation. The wheel bearings themselves allow the wheels to spin freely, which is essential for smooth driving. However, these components are subject to wear and tear, particularly because they are often exposed to various environmental factors, including mud, water, and debris.

The primary function of the seal is to keep the lubricant within the bearing assembly. Lubrication reduces friction, which helps in minimizing wear on the bearings. Without proper lubrication, the bearings can overheat, leading to premature failure. Additionally, the seals ensure that no foreign particles enter the bearings, which could cause significant damage over time.

Types of Seals

There are several types of front wheel bearing seals, each designed for specific applications. The most common types are the rubber lip seal, metal shielded seal, and the labyrinth seal.

1. Rubber Lip Seal This is the most commonly used seal. Its flexible lip creates a tight fit against the bearing surfaces, preventing contaminants from entering while holding in lubricants effectively.

2. Metal Shielded Seal This seal consists of metal that provides a barrier to dirt and debris. It has less resistance to turning motion compared to rubber lip seals but is effective in environments with less abrasive contaminants.

3. Labyrinth Seal These seals utilize a series of grooves or contours to create a tortuous path that contaminants must navigate to reach the bearings. They are often used in high-performance applications where utmost reliability is required.

front wheel bearing seal

Signs of Seal Failure

Over time, front wheel bearing seals can become damaged or worn out. Recognizing the signs of seal failure is essential for timely maintenance. Common symptoms include

- Grinding Noise A grinding or humming sound coming from the wheel area during driving can indicate that the bearings are not adequately lubricated due to a seal failure.

- Excessive Heat If the wheel assembly feels excessively hot during operation, this may be a sign that the bearings are overheating due to a lack of lubrication.

- Grease Leakage Visible grease leaking from around the wheel area is a clear indication of a compromised seal.

If any of these symptoms are present, it is crucial to inspect the front wheel bearing seals and replace them if necessary.

Maintenance and Replacement

Regular vehicle maintenance plays a significant role in the longevity of front wheel bearing seals. Inspections during routine service can identify premature wear or potential issues before they escalate.

When replacing front wheel bearing seals, it is essential to choose high-quality components that meet or exceed OEM specifications. Proper installation and torque specifications are also critical to ensure the seal's effectiveness. A professional mechanic should perform this task to avoid issues down the line.

In conclusion, front wheel bearing seals are essential for the health and efficiency of a vehicle's wheel assembly. Understanding their function, types, signs of failure, and maintenance procedures can help vehicle owners ensure optimal performance and safety on the road. Regular attention to these small yet critical components can save time, money, and promote a safer driving experience.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories