Nov . 25, 2024 02:52 Back to list

Hydraulic Seals for Forklift Cylinders Enhancing Performance and Durability

Understanding Forklift Hydraulic Cylinder Seals

Forklifts are essential pieces of equipment in warehouses, construction sites, and various industrial sectors, primarily used for lifting and transporting heavy loads. The efficiency of these machines largely depends on their hydraulic systems, which utilize hydraulic cylinders to lift and lower loads. Central to these hydraulic systems are the seals used in hydraulic cylinders, which play a critical role in ensuring that these systems operate smoothly and efficiently.

Understanding Forklift Hydraulic Cylinder Seals

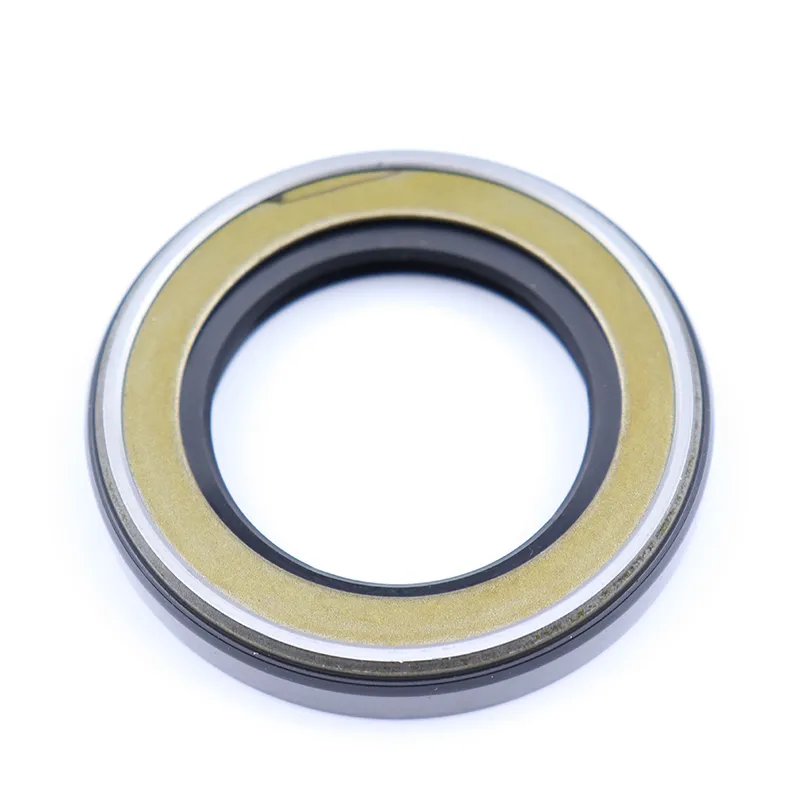

There are several types of seals used in hydraulic cylinders, including rod seals, piston seals, and buffer seals. Rod seals are placed at the exterior of the cylinder and are responsible for preventing hydraulic fluid from leaking out as the piston moves. Piston seals, on the other hand, prevent fluid from escaping between the piston and the cylinder wall, maintaining the pressure required for lifting operations. Buffer seals, typically positioned between the rod seal and the pressure side of the hydraulic cylinder, protect against contaminants and provide additional support against fluid leakage.

forklift hydraulic cylinder seals

The material and design of these seals are crucial factors that affect their performance and longevity. Common materials used for hydraulic seals include rubber compounds like nitrile, polyurethane, and fluorocarbon. Each material has its advantages; for instance, nitrile seals are known for their resistance to wear and hardness, while fluorocarbon seals offer better performance in extreme temperature conditions and chemical exposure. The choice of seal material depends on the working conditions and specific requirements of the forklift application.

Maintenance of hydraulic cylinder seals is essential for ensuring the longevity and reliability of the forklift’s hydraulic system. Regular inspections can help detect leaks, wear, and damage early, preventing costly repairs and downtime. Signs of wear may include reduced lifting capacity, fluid accumulation around the seals, and increased operational noise. If any issues are detected, timely replacement of seals is crucial to restore full functionality.

In conclusion, hydraulic cylinder seals are vital components in the effective operation of forklifts. They ensure that hydraulic systems function appropriately by preventing fluid leakage and maintaining pressure. Understanding the types of seals and their materials, as well as implementing regular maintenance, can significantly extend the life of hydraulic systems in forklifts, leading to improved performance and safety in industrial operations. Investing time and resources into the care of these seals not only enhances the productivity of material handling equipment but also contributes to the overall safety and efficiency of workplace operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories