Dec . 19, 2024 07:49 Back to list

felt wiper seals

The Importance of Felt Wiper Seals in Industrial Applications

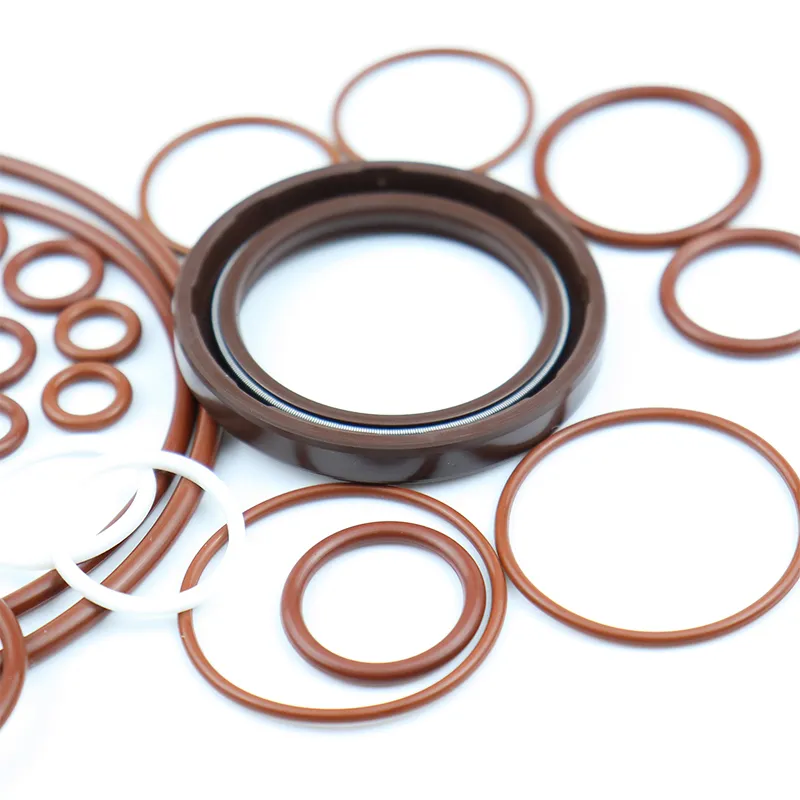

Felt wiper seals are an essential component in various industrial applications, providing a critical solution for sealing mechanisms and preventing contaminants from entering equipment. These seals are made from a dense and durable felt material that effectively retains lubricants while keeping dirt, dust, and debris at bay. As industries continue to seek efficiency and reliability, the role of felt wiper seals becomes increasingly significant.

Construction and Design

Felt wiper seals are typically designed as thin, flexible strips of felt that can be customized to fit various applications. Their manufacturing process involves compressing natural or synthetic fibers into a dense mat, which offers both resilience and adaptability. The felt material is chosen for its excellent compressibility and ability to maintain its shape under pressure. This unique property allows felt wiper seals to conform to surfaces while preventing leakage and contamination.

The design of these seals can vary based on specific requirements, including dimensions, thickness, and the type of adhesive used for attachment. Manufacturers often provide options for both standard and custom sizes to meet the unique needs of different machinery. This level of customization ensures that felt wiper seals can be effectively utilized in an array of environments, from automotive applications to heavy machinery.

Applications Across Industries

Felt wiper seals are predominantly used in environments where oil or grease is present, as they can effectively contain lubricants within the system. Common applications include machinery in manufacturing plants, automotive components, construction equipment, and even household appliances. For instance, in hydraulic cylinders, felt wiper seals prevent dirt and moisture from entering the cylinder, thus extending its lifespan and enhancing performance.

In the automotive industry, felt wiper seals play a vital role in components such as doors and windows, where they aid in reducing noise, controlling dust ingress, and promoting thermal insulation. The effective sealing capabilities of felt wipers ensure that vehicles operate more efficiently and meet the necessary standards for environmental performance.

felt wiper seals

Benefits of Felt Wiper Seals

One of the key advantages of felt wiper seals is their ability to absorb and retain lubricants. This not only minimizes wear on moving parts but also ensures that the components operate smoothly over time. By acting as a barrier to contaminants, felt wiper seals help reduce maintenance costs and downtime, contributing to overall operational efficiency.

Moreover, the adaptability of felt wiper seals allows them to perform well under various conditions, including extreme temperatures and pressures. Their resilience to wear and tear means that they offer a long service life, making them a cost-effective option for industries. Additionally, the ease of installation and replacement enhances their appeal, as businesses can quickly address wear issues without extensive downtime.

Environmental Considerations

In today’s environmentally conscious world, the use of sustainable materials is a growing concern. Felt wiper seals can be manufactured from recyclable materials, reducing their environmental impact. By opting for seals made from eco-friendly fibers, companies can contribute to sustainability goals without compromising on performance.

Conclusion

Felt wiper seals represent a remarkable blend of functionality, durability, and adaptability, making them indispensable in various industrial applications. Their ability to protect machinery from contaminants while retaining essential lubricants contributes significantly to the efficiency and longevity of equipment. As industries continue to innovate and prioritize sustainability, felt wiper seals will undoubtedly remain a critical component in maintaining operational excellence. By understanding their importance and applications, businesses can make informed decisions that enhance performance and reliability across their operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories