Aug . 01, 2024 02:57 Back to list

Exploring the Essential Role of Hydraulic Press Oil Seals in Machinery Performance and Efficiency

The Importance of Oil Seals in Hydraulic Press Applications

Hydraulic presses are powerful machines widely used across various industries for shaping, molding, and compressing materials. One crucial component in ensuring the efficient and safe operation of a hydraulic press is the oil seal. This article delves into the significance of oil seals in hydraulic press systems, their types, and their role in maintaining hydraulic fluid integrity.

What is an Oil Seal?

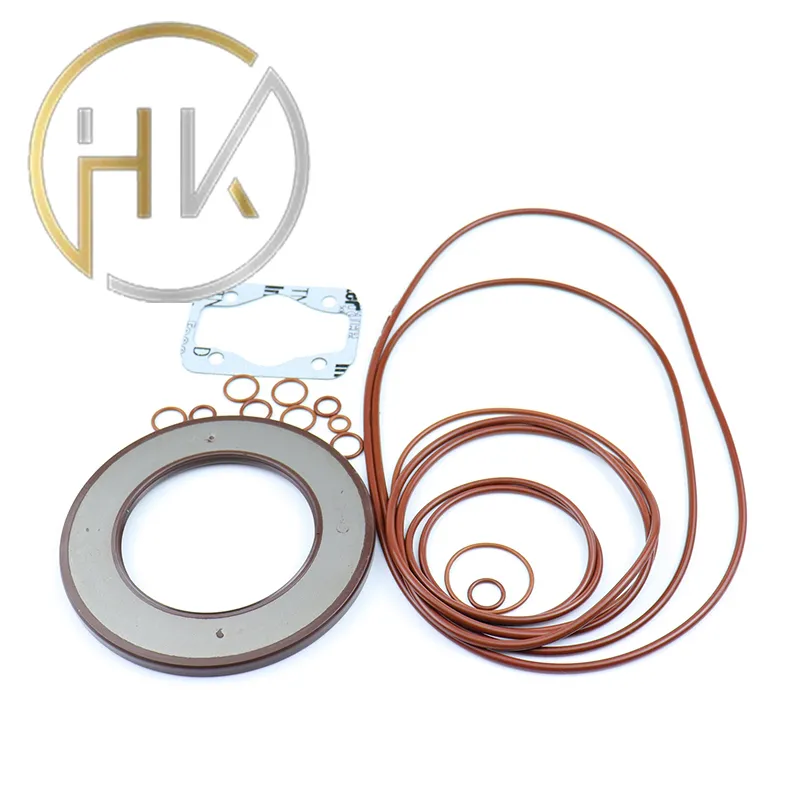

An oil seal, also known as a fluid seal, is designed to prevent the leakage of hydraulic fluid from the system while simultaneously protecting the internal components from dirt, dust, and other contaminants. Typically made of rubber, polyurethane, or other elastomeric materials, oil seals come in a range of shapes and sizes, tailored to fit specific applications. In a hydraulic press, oil seals play an essential role in maintaining pressure and ensuring smooth operation.

Types of Oil Seals

Various types of oil seals are used in hydraulic applications, including

1. Lip Seals These seals have a flexible lip that contacts the shaft. They are the most common type used in hydraulic presses, offering excellent sealing capabilities and accommodating shaft misalignment.

2. O-Rings Though primarily used for static sealing applications, O-rings can also be found in dynamic applications where sealing against pressure is required. They are circular in shape and provide a simple yet effective sealing solution.

3. Piston Seals These seals are used in the hydraulic cylinders of the press. They help maintain pressure while allowing smooth movement of the piston, thus optimizing performance.

hydraulic press oil seal

4. Rotary Seals While not as common in hydraulic presses, rotary seals are used in applications where components need to rotate, such as in certain hydraulic machinery.

Role of Oil Seals in Hydraulic Presses

The oil seal's primary function in a hydraulic press is to retain hydraulic fluid within the system. By providing a secure seal, they prevent the loss of hydraulic fluid, which is essential for generating and maintaining the pressure needed for the press's operation. A well-functioning oil seal ensures that the hydraulic fluid remains uncontaminated, which is vital for the longevity and efficiency of the hydraulic components.

Leakage due to failed or ineffective oil seals can lead to reduced performance, increased maintenance costs, and potential safety hazards. In extreme cases, it may even cause catastrophic failures, resulting in downtime and significant financial losses. Therefore, employing quality oil seals and conducting regular inspections is crucial for the maintenance of hydraulic presses.

Choosing the Right Oil Seal

Selecting the appropriate oil seal for a hydraulic press involves considering several factors, including operating temperature, pressure levels, the compatibility of the seal material with the hydraulic fluid, and the specific design of the press. Utilizing high-quality seals that meet industry standards can result in enhanced performance and reduced maintenance needs.

Conclusion

In conclusion, oil seals are integral components of hydraulic press systems, playing a vital role in ensuring the efficiency and reliability of operations. By preventing fluid leakage and protecting against contamination, they contribute significantly to the overall performance and longevity of the press. Therefore, industries relying on hydraulic presses must prioritize the selection, installation, and maintenance of oil seals to enhance productivity and minimize operational disruptions. Investing in quality oil seals is not just a maintenance task; it's a step towards ensuring the success and sustainability of hydraulic operations in any production environment.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories