Aug . 13, 2024 00:36 Back to list

Exploring the Benefits of 40 Percent Natural Rubber in 80 Percent Oil Seal Applications

The 40% – 80% – 10% Oil Seal Concept A Powerful Tool in Engineering

In the world of engineering and manufacturing, the reliability and efficiency of machines and components hinge on their ability to perform under pressure and extreme conditions. One crucial component that often goes unnoticed but plays a significant role in ensuring this reliability is the oil seal. This article delves into the concept of the 40% – 80% – 10% oil seal, examining its importance in contemporary engineering practices.

Understanding Oil Seals

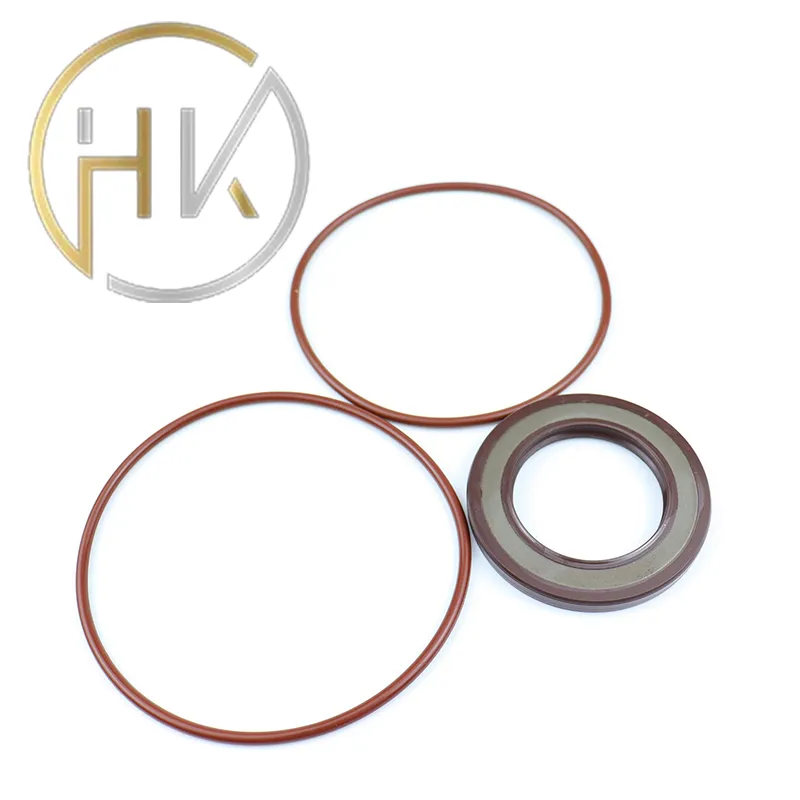

Oil seals are mechanical devices used to seal the gap between stationary and moving components in machinery. Their primary function is to prevent the leakage of lubricants and the entry of contaminants, which can adversely affect the performance and lifespan of the equipment. The structure of an oil seal typically includes a flexible sealing lip made of rubber or elastomeric material, a metal casing, and a spring mechanism to maintain contact with the shaft.

The 40% – 80% – 10% Concept Explained

The 40% – 80% – 10% concept offers a framework to analyze the performance and effectiveness of oil seals in various applications. This framework breaks down the oil sealing process into three primary categories

1. 40% – Material Selection The choice of materials is critical to the effectiveness of oil seals. High-quality elastomers, such as nitrile rubber or fluorocarbon, ensure durability and resistance to a wide range of temperatures and chemicals. Engineers must evaluate the operational environment of the seal, including exposure to oil types, temperatures, and potential contaminants. Therefore, the material selection constitutes about 40% of the overall effectiveness of the oil seal.

40 80 10 oil seal

2. 80% – Design Efficiency While material selection is crucial, the design of the oil seal is arguably more important, contributing approximately 80% to its overall performance. Effective design encompasses various factors, including lip geometry, sealing pressure, and tolerance to misalignment. A well-designed oil seal can accommodate thermal expansion, vibration, and axial or radial movements, thus improving its sealing capabilities. Advanced designs may also incorporate features such as double lips or integrated wipers to enhance sealing performance further.

3. 10% – Installation and Maintenance Finally, the remaining 10% emphasizes the significance of proper installation and routine maintenance. An oil seal, regardless of its materials and design, cannot function effectively if not installed correctly. Factors such as alignment, fit, and surface finishing play critical roles in ensuring the longevity and efficiency of the seal. Regular maintenance checks can help identify wear and tear early, allowing for proactive replacements before leaks occur.

Applications and Implications

The 40% – 80% – 10% framework provides engineers with a structured approach to evaluating and improving oil seals used in various machinery, from automotive engines to industrial pumps. By focusing on materials and design efficiency, engineers can optimize performance while also ensuring long-term reliability. Ignoring any aspect of this framework can lead to failures, which may result in costly downtime and repairs.

Conclusion

The 40% – 80% – 10% oil seal concept serves as a powerful tool for engineers dedicated to enhancing the reliability and efficiency of their machinery. By understanding the significance of material selection, design considerations, and the importance of proper installation, engineers can ensure the optimal performance of oil seals. This multifaceted approach not only ensures machinery operates smoothly but also contributes to cost savings and sustained operational excellence. As technology continues to advance, refining these principles is crucial for future innovations in sealing solutions.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories