Jul . 31, 2024 00:49 Back to list

Exploring Seal Kit Cylinder Applications and Benefits for Industrial Machinery Performance Improvement

The Importance of Seal Kit Cylinders in Hydraulic Systems

Hydraulic systems play a pivotal role in numerous industries, from manufacturing to construction. At the heart of these systems lies the hydraulic cylinder, which converts hydraulic energy into mechanical energy. However, the functionality and longevity of hydraulic cylinders heavily depend on one crucial component the seal kit cylinder.

What is a Seal Kit Cylinder?

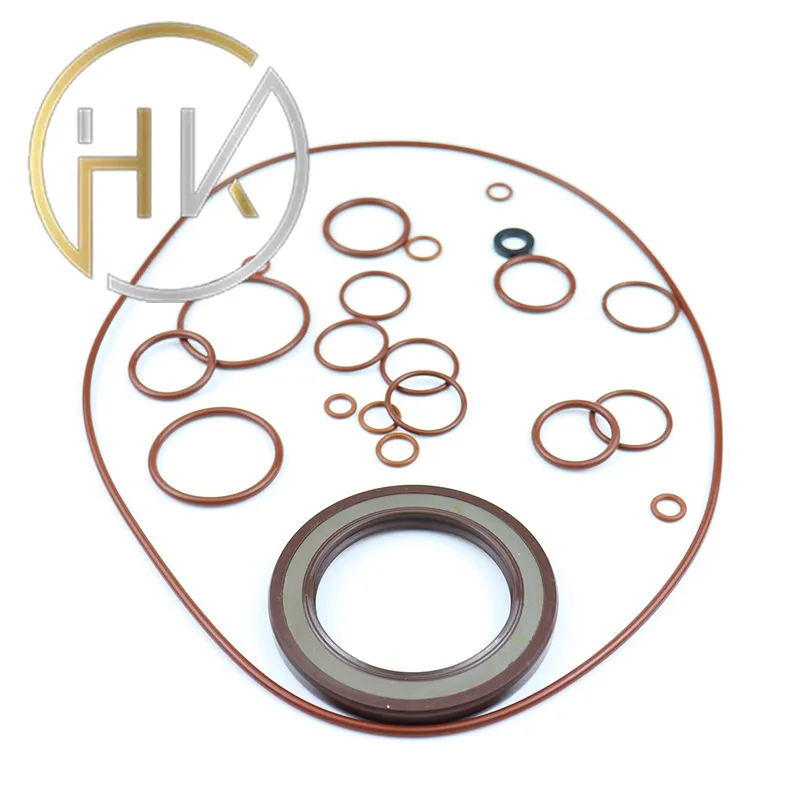

A seal kit cylinder, often referred to simply as a seal kit, is an assembly of various seals designed to prevent hydraulic fluid from leaking out of the cylinder and to keep contaminants from entering. These seal kits are typically made from materials like rubber, polyurethane, or specialty compounds that can withstand high pressures and temperatures. They ensure optimal performance and are essential for maintaining the integrity of hydraulic systems.

The Role of Seal Kits in Hydraulic Systems

The primary function of a seal kit is to provide a reliable barrier between different elements within the hydraulic cylinder. This is essential for the following reasons

1. Leak Prevention Hydraulic fluids are often expensive and can cause environmental hazards when spilled. A well-maintained seal kit ensures that these fluids remain contained within the system, preventing costly leaks that can lead to downtime and repairs.

2. Contaminant Exclusion Contaminants such as dirt, dust, and moisture can severely affect the performance of hydraulic systems. Seal kits act as a defense mechanism, safeguarding the internal components of the cylinder from harmful particles that could lead to wear and tear or even failure.

3. Pressure Maintenance Hydraulic systems operate under significant pressure, and maintaining this pressure is vital for effective functioning. Seal kits allow cylinders to maintain optimal pressure levels, ensuring that machinery operates efficiently and with the necessary force.

seal kit cylinder

4. Enhanced Longevity By preventing leaks and contamination, seal kits contribute to the overall lifespan of hydraulic cylinders. Regular maintenance and timely replacement of seal kits can lead to fewer breakdowns and reduced repair costs, making operations more cost-effective in the long run.

Choosing the Right Seal Kit

Selecting the right seal kit cylinder is essential for the performance of hydraulic equipment. Factors to consider include

- Material Compatibility Different hydraulic fluids have varying chemical properties. It’s crucial to choose seal materials that are compatible with the specific fluids being used to prevent degradation and failure.

- Operating Conditions The working environment, temperature, and pressure levels should guide the selection of seal kits. High-pressure applications may require specialized seals that can withstand extreme conditions.

- Manufacturer Specifications Always refer to the manufacturer’s specifications for hydraulic cylinders when selecting a seal kit. This ensures that the seals fit correctly and function as intended.

Conclusion

In conclusion, seal kit cylinders are a fundamental component of hydraulic systems that ensure efficiency, safety, and longevity. Their role in preventing leaks and contamination cannot be overstated. By investing in high-quality seal kits and adhering to maintenance schedules, industries can enhance the performance of their hydraulic systems and ultimately achieve better operational outcomes. Understanding the significance of seal kits, and making informed choices about them, is crucial for anyone working with hydraulic machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories