Aug . 09, 2024 23:15 Back to list

Exploring Advanced High-Pressure Hydraulic Shaft Seals for Enhanced Performance and Reliability in Machinery

Understanding High-Pressure Hydraulic Shaft Seals

In the realm of fluid power technology, high-pressure hydraulic shaft seals play a critical role in ensuring the efficient operation and longevity of hydraulic systems. These seals are designed to prevent the leakage of hydraulic fluid under high-pressure conditions, which can exceed several thousand psi, depending on the application. Their importance cannot be overstated, as they help maintain system integrity, reduce maintenance costs, and enhance operational safety.

What are High-Pressure Hydraulic Shaft Seals?

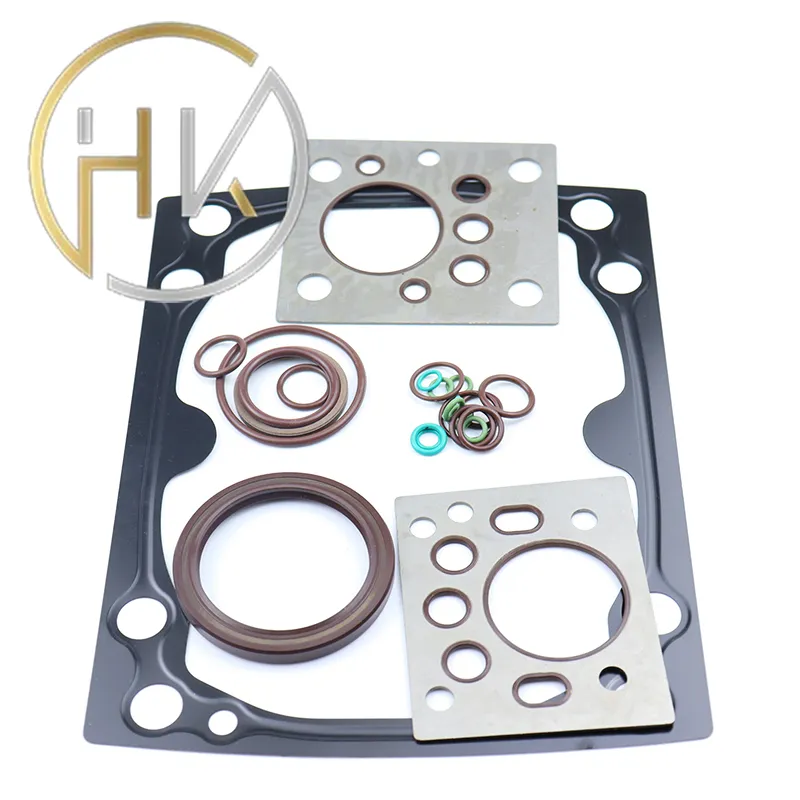

High-pressure hydraulic shaft seals are specially engineered components that function as barriers between rotating shafts and stationary parts of hydraulic machinery. Typically made from durable materials such as polyurethane, nitrile, or PTFE (Teflon), these seals are capable of withstanding extreme pressures and challenges presented by the operating environment.

The primary purpose of hydraulic seals is to contain hydraulic fluid within the system while allowing the shaft to rotate freely. By achieving a proper seal, these components prevent fluid from leaking out and contaminants from entering, which can cause system failure or inefficiency.

Types of High-Pressure Hydraulic Shaft Seals

There are several types of high-pressure hydraulic shaft seals, each designed for specific applications and operational needs. The common types include

1. U-Cups These seals have a U-shaped cross-section and are among the most widely used types in hydraulic applications. U-cups work by utilizing the hydraulic pressure to increase the contact between the seal and the shaft, offering effective sealing even at high pressures.

2. O-Rings While commonly used in static sealing applications, O-rings can also be employed in dynamic sealing situations, particularly in low-speed environments. Their simplicity and effectiveness make them a staple in various hydraulic setups.

3. Lip Seals These are commonly used in rotating applications. Lip seals feature a flexible lip that conforms to the shaft, providing an excellent seal against high-pressure fluids while also allowing for smooth shaft rotation.

high pressure hydraulic shaft seals

Applications of High-Pressure Hydraulic Shaft Seals

High-pressure hydraulic shaft seals are utilized in a multitude of applications across various industries. These applications include

- Industrial Machinery They are critical components in hydraulic presses, molding machines, and other industrial equipment that rely on hydraulic fluid for operation.

- Automotive In vehicles, hydraulic seals are vital in braking systems, power steering mechanisms, and hydraulic lifts.

- Aerospace High-pressure seals must meet stringent safety and reliability standards in aviation applications, ensuring operational safety in hostile environments.

- Construction and Mining Hydraulic equipment such as excavators and loaders rely on robust seals to maintain performance under heavy loads and adverse conditions.

Challenges and Considerations

While high-pressure hydraulic shaft seals are designed for durability, selecting the right seal for a specific application requires careful consideration of factors such as the type of fluid used, operating temperature, shaft speed, and the potential for contamination. The wrong choice can lead to premature seal failure, fluid contamination, and costly downtime.

Moreover, regular maintenance and inspection of hydraulic seals are essential to ensure optimal performance. Signs of wear, such as discoloration, cracking, or deformation, should be addressed promptly to prevent severe system issues.

Conclusion

High-pressure hydraulic shaft seals are integral to the functionality and reliability of hydraulic systems across diverse applications. Understanding their types, functions, and suitable applications is crucial for engineers, technicians, and operators alike. As technology advances, innovations in sealing materials and designs continue to emerge, promising enhanced efficiency and longevity in hydraulic operations. By investing in quality seals and adhering to best maintenance practices, industries can ensure their hydraulic systems remain robust and efficient in demanding conditions.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories