Oct . 09, 2024 04:49 Back to list

Excavator Cylinder Seal Kits for Enhanced Performance and Reliability in Heavy Machinery

Understanding Excavator Cylinder Seal Kits Importance and Benefits

Excavators are vital machines in the construction and mining industries, known for their ability to perform heavy-duty tasks like digging, lifting, and moving materials. A crucial component of excavators is the hydraulic cylinder, which relies on efficient sealing to maintain hydraulic pressure and performance. This is where excavator cylinder seal kits come into play.

What Are Excavator Cylinder Seal Kits?

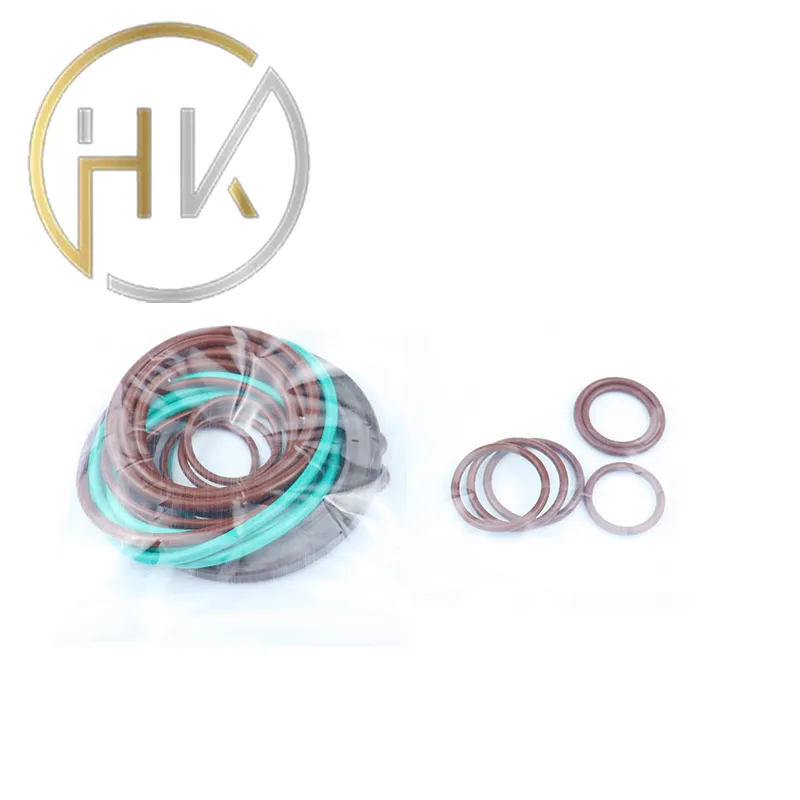

Excavator cylinder seal kits consist of various seals and o-rings made from durable materials designed to prevent hydraulic fluid leaks. These kits typically include piston seals, rod seals, backup rings, and wipers, all working together to ensure the hydraulic cylinders function effectively. Each seal has a specific purpose; for instance, piston seals keep the hydraulic fluid contained within the cylinder during movement, while rod seals prevent external contaminants from entering the hydraulic system.

Importance of High-Quality Seal Kits

The integrity of hydraulic systems directly impacts an excavator's efficiency and operational capabilities. Poor-quality seal kits can lead to leaks, reducing hydraulic pressure and causing performance issues. Over time, this can result in decreased operational efficiency, leading to more frequent repairs and higher maintenance costs. High-quality seal kits, on the other hand, enhance the machine’s reliability, improve its lifespan, and reduce the likelihood of unexpected downtime.

excavator cylinder seal kits

Using genuine or OEM (Original Equipment Manufacturer) seal kits ensures that the seals are specifically designed for your excavator's model. This minimizes the risk of improper fit or material incompatibility, which can compromise functionality.

Benefits of Regular Maintenance

Regular maintenance of excavator hydraulic systems, including timely replacement of cylinder seal kits, is essential for optimal performance. Ignoring wear and tear on seals can lead to extensive damage within the hydraulic system, often requiring costly repairs or even replacement of the entire hydraulic cylinder.

Moreover, proactive maintenance can enhance efficiency by ensuring maximum hydraulic power and control. This not only improves productivity on the job site but also ensures the safety of operators and other personnel present.

Conclusion

In summary, excavator cylinder seal kits are indispensable for maintaining the efficiency and functionality of hydraulic cylinders in excavators. Investing in high-quality seal kits and prioritizing regular maintenance can lead to significant operational benefits, prolonged equipment life, and reduced costs in the long run. Whether you are operating a single excavator or managing a fleet, understanding the importance of these seal kits is crucial for ensuring that your machines remain in top working condition, ready to tackle the toughest jobs on site.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories