Nov . 28, 2024 09:55 Back to list

Excavator Boom Cylinder Seal Change Guide for Optimal Performance and Longevity

Excavator Boom Cylinder Seal Replacement A Comprehensive Guide

Maintaining the performance and longevity of your excavator is crucial for any heavy equipment operator. One critical component that often requires attention is the boom cylinder. The boom cylinder is responsible for the lifting action of the boom, and over time, wear and tear can lead to seal failures. A leaking boom cylinder can significantly affect the machine’s performance and efficiency. This article offers a comprehensive guide on how to replace the seals in your excavator's boom cylinder.

Understanding the Boom Cylinder

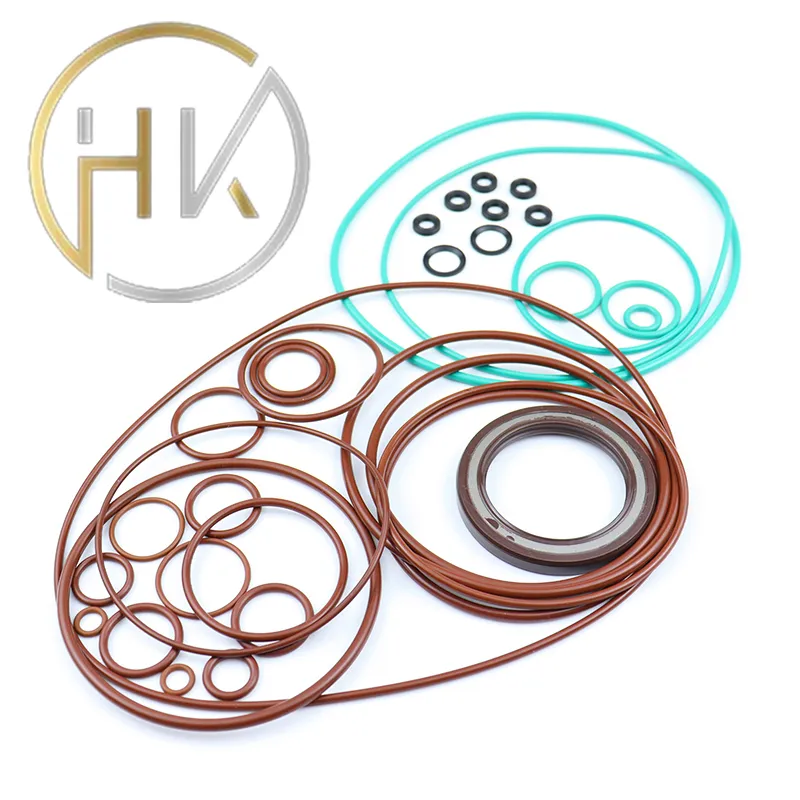

The boom cylinder operates by using hydraulic fluid to create power. It comprises several parts, including the cylinder tube, piston, and seals. Seals are essential as they prevent hydraulic fluid from leaking out of the cylinder and ensure that the system operates efficiently. Common signs that your seals may need replacement include leaking hydraulic fluid, decreased lifting capacity, and unusual noises during operation.

Tools and Materials Needed

Before starting the replacement process, ensure you have the following tools and materials

- Wrenches and socket sets - Screwdrivers - Snap ring pliers - Hydraulic seal kit compatible with your excavator model - Cleaning solvents and rags - Torque wrench - Safety goggles and gloves

Step-by-Step Guide to Seal Replacement

1. Safety First

Before you begin, ensure the excavator is on a flat surface, and all hydraulic systems are depressurized. Use safety goggles and gloves to protect yourself from any potential hazards.

2. Remove the Boom Cylinder from the Excavator

To access the seals, you need to detach the boom cylinder from the excavator. Start by removing any attachments or hoses connected to the cylinder. Use appropriate wrenches to unbolt the cylinder from its mounting points. Once detached, carefully lower the cylinder to a safe workspace.

3. Disassemble the Boom Cylinder

excavator boom cylinder seal replacement

Once on a stable platform, remove the end cap of the boom cylinder using your wrench set. Carefully slide out the piston and take note of the arrangement of each part as you disassemble it. This is crucial for reassembly.

4. Inspect Components

Before replacing the seals, inspect the cylinder tube and piston for any signs of damage or excessive wear. If you notice significant damage, it might be necessary to replace the entire cylinder instead of just the seals.

5. Replace the Seals

Remove the old seals from the piston and the cylinder tube. Clean the surfaces thoroughly using cleaning solvents to ensure no debris or old seal material remains. Take the new seals from your hydraulic seal kit and carefully place them into their respective grooves. Make sure they sit evenly and are free from twists or damages.

6. Reassemble the Boom Cylinder

Once the new seals are in place, reinsert the piston into the cylinder. Ensure that everything is aligned correctly as you reattach the end cap. Use a torque wrench to tighten the bolts to the manufacturer’s specifications to avoid any leaks.

7. Reattach the Boom Cylinder

With the boom cylinder fully reassembled, lift it back into position and reattach it to the excavator. Ensure all hoses and attachments are securely fastened.

8. Test for Leaks

After the cylinder is reattached, refill the hydraulic system if necessary and depressurize it. Start the excavator and operate the boom to check for any leaks. Monitor the cylinder closely during its operation to ensure everything is functioning correctly.

Conclusion

Replacing the boom cylinder seals in your excavator is a vital maintenance task that can prevent larger issues down the line. By following this detailed guide, you can ensure that your equipment remains in top condition, enhancing its efficiency and your productivity. Regular inspections and timely replacements can save both time and money, ensuring that your excavator is always ready for the job at hand.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories