Oct . 04, 2024 19:36 Back to list

excavator boom cylinder seal replacement

Excavator Boom Cylinder Seal Replacement A Comprehensive Guide

Maintaining the functionality of an excavator is crucial for efficiency on construction sites. One of the essential components that require regular attention is the boom cylinder. The boom cylinder is responsible for lifting and lowering the excavator's boom, making it vital for various tasks. Over time, seals in the boom cylinder can wear out or get damaged, leading to hydraulic fluid leaks and decreased performance. This article will guide you through the process of replacing the seals in your excavator's boom cylinder.

Importance of Seal Replacement

The seals in hydraulic cylinders serve a critical role in maintaining pressure and preventing fluid from leaking. If the seals fail, it can result in a loss of hydraulic power, which affects the entire operation of the excavator. Additionally, leaks can lead to environmental concerns and costly repairs if left unaddressed. Therefore, timely seal replacement is necessary for optimal performance and longevity of your equipment.

Symptoms of Worn Seals

Before undertaking a seal replacement, it’s essential to identify the signs of seal wear. Common symptoms include

1. Hydraulic Fluid Leakage Noticeable fluid pooling or dripping from the boom cylinder is a clear indicator. 2. Decreased Lifting Power If the boom fails to lift loads as it once did, worn seals may be the culprit. 3. Slow Cylinder Movement A delay or sluggish movement of the boom during operation can indicate hydraulic pressure loss due to seal failure. 4. Strange Noises Unusual sounds while operating the boom can suggest that the seals are compromised, leading to hydraulic fluid bypassing the seals.

Tools and Materials Required

Before beginning the replacement process, ensure you have the necessary tools and materials on hand

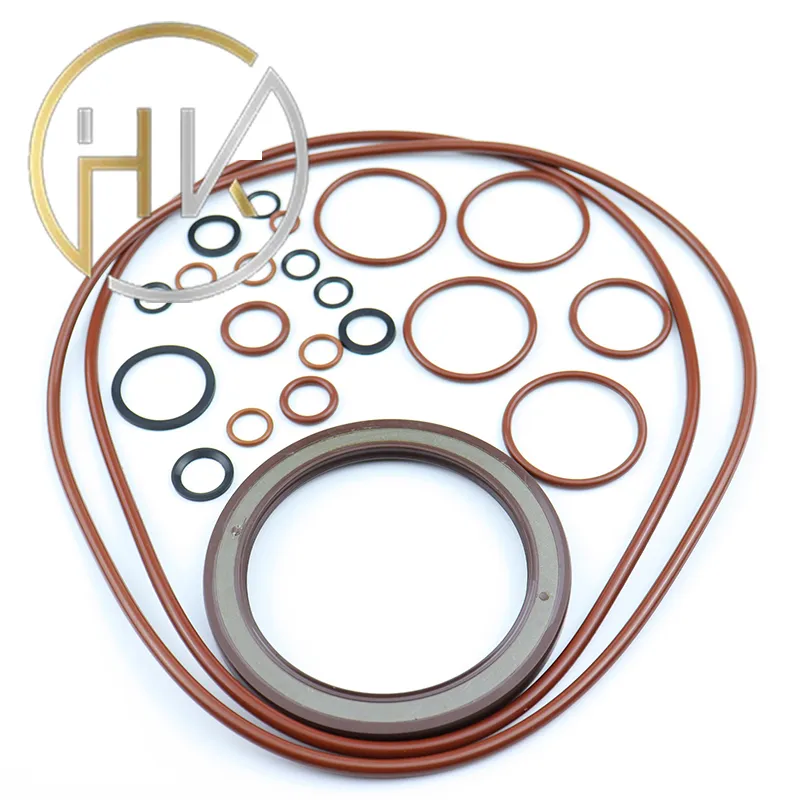

- Replacement seals specific to your excavator model - Hydraulic jack or crane - Wrenches and sockets - Seal removal kit (including picks and scrapers) - Clean rag or absorbent material for hydraulic fluid - Hydraulic oil for refilling the cylinder - Safety goggles and gloves

Step-by-Step Replacement Process

1. Preparation Park the excavator on a level surface and engage the parking brake. Disconnect the battery to ensure safety during the procedure.

excavator boom cylinder seal replacement

2. Remove the Boom Use a hydraulic jack or crane to support the boom. Carefully detach the boom from the excavator’s arm by removing the pins and any necessary bolts.

3. Drain the Hydraulic Fluid Position a container underneath the boom cylinder and remove the drain plug to collect any remaining hydraulic fluid.

4. Disassemble the Cylinder Remove the end caps or mounting brackets to access the internal components of the boom cylinder. Carefully slide the piston out, taking care not to damage the cylinder walls.

5. Remove Old Seals Use a seal removal tool to extract the old seals from their grooves. Clean the surfaces thoroughly, removing any debris or old seal material.

6. Install New Seals Carefully install the new seals in their respective grooves. Make sure to lubricate the seals with a small amount of hydraulic fluid before installation to ensure a proper fit.

7. Reassemble the Cylinder Once the new seals are in place, reinsert the piston into the cylinder and reattach the end caps or mounting brackets securely.

8. Reconnect the Boom Carefully reposition the boom onto the excavator and secure it with the removed pins and bolts.

9. Refill Hydraulic Fluid Fill the hydraulic system with the appropriate type of fluid to the recommended level, following manufacturer specifications.

10. Test the System Reconnect the battery and operate the boom to ensure everything functions correctly. Check for leaks around the newly installed seals and verify that lifting power has returned to normal.

Conclusion

Replacing the seals in your excavator’s boom cylinder may seem daunting, but with the right tools and careful attention to detail, it can be accomplished safely and efficiently. Routine maintenance and timely seal replacement are essential for ensuring the reliability and effectiveness of your excavator. Always consult your equipment’s service manual for specific instructions and safety measures concerning your model. Keeping your excavator in top condition will ultimately save you time and money on repairs, enhancing your productivity on the job.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories