Aug . 10, 2024 05:10 Back to list

Essential Components for Restoring Hydraulic Cylinder Performance with Seal Repair Kits

Understanding Hydraulic Cylinder Repair Seal Kits

Hydraulic cylinders play a pivotal role in various mechanical systems, including construction machinery, agricultural equipment, and industrial machines. They convert hydraulic energy into linear motion and are essential for effectiveness and efficiency in various operations. However, like any mechanical component, hydraulic cylinders can experience wear and tear over time. One of the most common issues that arise is the failure of seals. This is where hydraulic cylinder repair seal kits come into play.

What is a Hydraulic Cylinder Seal Kit?

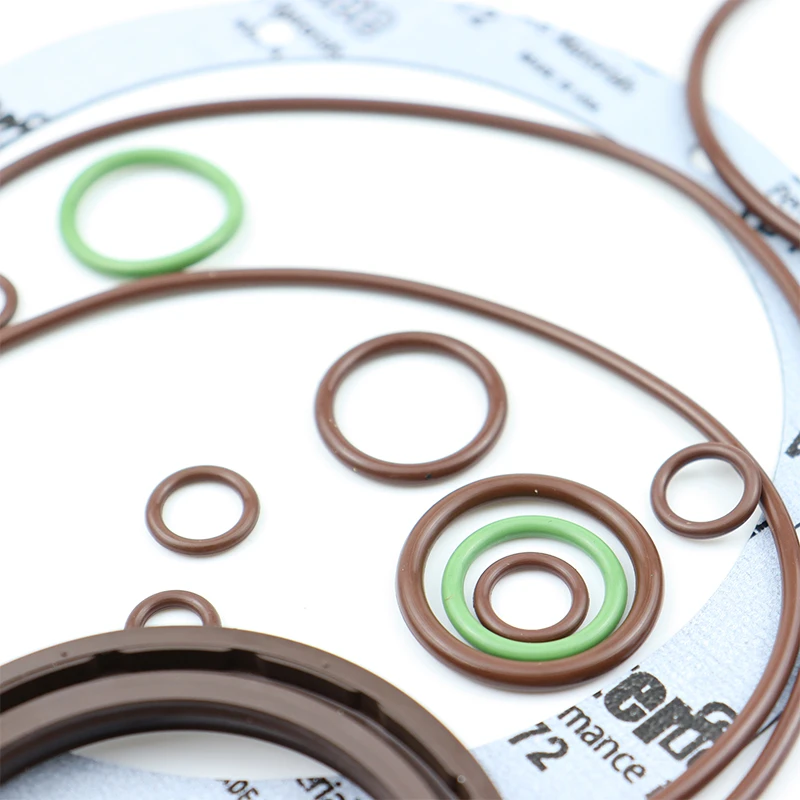

A hydraulic cylinder repair seal kit is a collection of replacement seals, O-rings, and other components designed for the refurbishment of hydraulic cylinders. These kits are crucial for maintaining the integrity and performance of hydraulic systems. When hydraulic fluids leak, it not only reduces efficiency but can also lead to more extensive damage, resulting in costly repairs and downtime.

Components of a Seal Kit

The exact contents of a hydraulic cylinder repair seal kit can vary depending on the specific application and cylinder design. However, most kits typically include

1. Seal Rings These are the primary components responsible for preventing fluid leaks. They can be made from various materials, including rubber, polyurethane, or PTFE, depending on the fluid being used and the operating conditions.

2. O-Rings Similar to seal rings, O-rings provide additional sealing protection and are commonly used in various parts of hydraulic cylinders.

3. Backup Rings These rings help support the primary seals, particularly in high-pressure applications, and prevent extrusions.

5. Gaskets Used to create seals at junctions between different components, gaskets help maintain pressure and prevent leaks.

hydraulic cylinder repair seal kit

Signs Your Cylinder Might Need a Seal Kit

Recognizing the telltale signs of a failing seal can save time and money. Some indicators include

- Fluid Leaks Puddles or drips of hydraulic fluid under the machinery are immediate warning signs. - Reduced Performance If a hydraulic cylinder is not delivering expected force or speed, it may be due to seal degradation. - Unusual Noises Grinding or popping noises can indicate internal damage or air leakage, requiring immediate attention.

Benefits of Using a Repair Seal Kit

Investing in a hydraulic cylinder repair seal kit offers numerous advantages

1. Cost-Effective Repairing a hydraulic cylinder with a seal kit is typically much cheaper than replacing the entire unit. 2. Improved Performance Fresh seals can restore the hydraulic cylinder's functionality, enhancing the overall productivity of the equipment.

3. Extended Lifespan Regular maintenance, including the replacement of worn seals, can significantly increase the operational life of hydraulic systems.

4. Reduced Downtime Quick repairs with seal kits can minimize downtime, allowing for continued operation without extensive delays.

Conclusion

Hydraulic cylinder repair seal kits are essential tools for anyone who operates machinery relying on hydraulic systems. By understanding the importance of these kits and the various components within them, operators and maintenance personnel can ensure optimal performance and longevity of hydraulic cylinders. Regular inspection and timely repair can prevent minor issues from escalating, ensuring that equipment remains operational and efficient. Investing in quality repair kits not only protects machinery but also contributes to a smoother and more productive work environment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories