Jul . 28, 2024 09:16 Back to list

Efficient Hydraulic Dust Seals for Enhanced Equipment Longevity and Performance in Various Environments

Understanding Hydraulic Dust Seals Importance and Applications

Hydraulic systems are integral to various industrial applications, providing power through the controlled movement of fluid. One critical component in these systems is the hydraulic dust seal. Although often overlooked, this component plays a vital role in maintaining the efficiency and longevity of hydraulic machinery.

What is a Hydraulic Dust Seal?

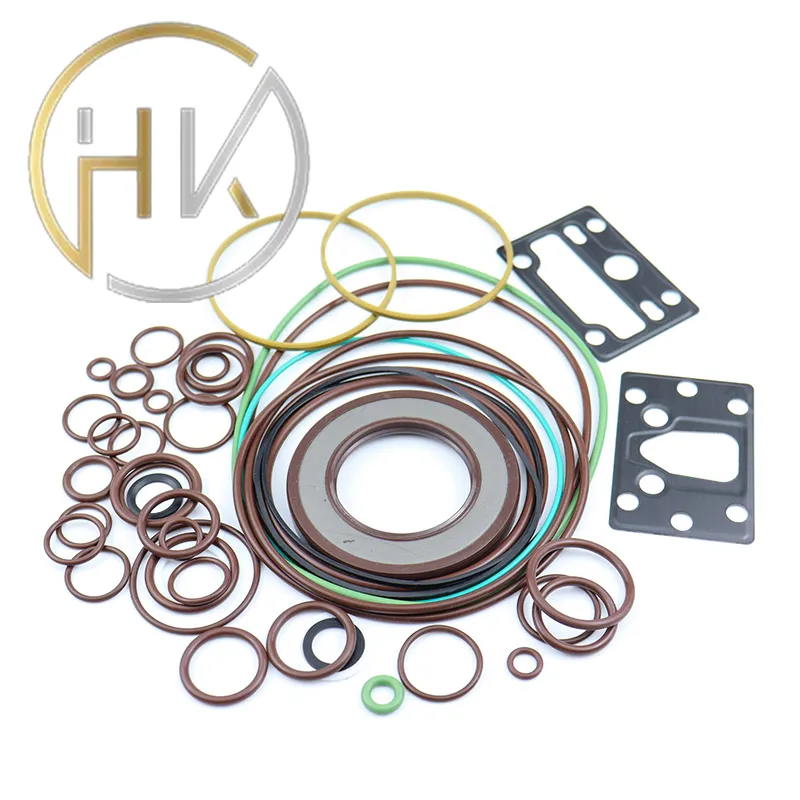

A hydraulic dust seal is designed to prevent dust, dirt, and other contaminants from entering the hydraulic system. Typically made from durable materials like rubber, polyurethane, or other elastomers, these seals are placed around moving parts, such as pistons and cylinders, to provide a barrier against environmental pollutants. The primary function of a hydraulic dust seal is to ensure that only the hydraulic fluid circulates within the system, protecting critical components from abrasive materials that can lead to wear and potential failure.

Importance of Hydraulic Dust Seals

1. Protection Against Contaminants In many industrial settings, equipment is exposed to dust and debris. Over time, these contaminants can infiltrate hydraulic systems, leading to increased wear and tear on the hydraulic components. Dust seals provide an essential line of defense, reducing the likelihood of system contamination.

2. Extending Equipment Life By preventing contaminants from entering the hydraulic mechanisms, dust seals contribute to extending the lifespan of hydraulic components. Less wear translates to fewer replacements and repairs, ultimately leading to lower maintenance costs and enhanced productivity.

3. Maintaining System Efficiency Contaminated hydraulic fluid can become less effective, leading to reduced performance of the machinery. By keeping the hydraulic fluid clean, dust seals help maintain optimal system efficiency and effectiveness, ensuring that machinery operates at its best.

4. Safety Considerations Hydraulic failures can lead to catastrophic equipment breakdowns, posing safety hazards not only to the machinery but also to the operators. Implementing hydraulic dust seals as part of a proactive maintenance strategy can mitigate these risks and promote a safer working environment.

hydraulic dust seal

Applications of Hydraulic Dust Seals

Hydraulic dust seals are widely used across various industries. Their applications include

- Construction Equipment Excavators, bulldozers, and cranes use hydraulic systems to facilitate powerful movements. Dust seals help protect these systems from dirt, gravel, and other construction-site debris.

- Agricultural Machinery Tractors and harvesters often operate in dusty and muddy conditions. Hydraulic dust seals ensure that their hydraulic systems remain protected, enhancing reliability and performance in the field.

- Automotive Industry Hydraulic systems in vehicles, such as braking systems and power steering, rely on effective dust seals to prevent contamination and maintain optimal performance.

- Manufacturing Equipment Machines that operate under high-stress conditions, such as presses and conveyors, utilize hydraulic dust seals to ensure longevity and efficiency.

Conclusion

In conclusion, hydraulic dust seals serve a critical function in various applications by protecting hydraulic systems from contaminants. Their role in extending the life of equipment, maintaining efficiency, and enhancing safety cannot be overstated. As industries continue to prioritize reliability and efficiency, integrating high-quality hydraulic dust seals into hydraulic machinery design and maintenance practices will remain a best practice. A small investment in these seals can lead to significant savings and improvements in operational performance, ultimately contributing to the overall success of industrial operations.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories