Aug . 13, 2024 14:42 Back to list

Effective Solutions for Dust Wiper Seals to Enhance Equipment Performance and Longevity

Understanding Dust Wiper Seals Essential Components for Mechanical Systems

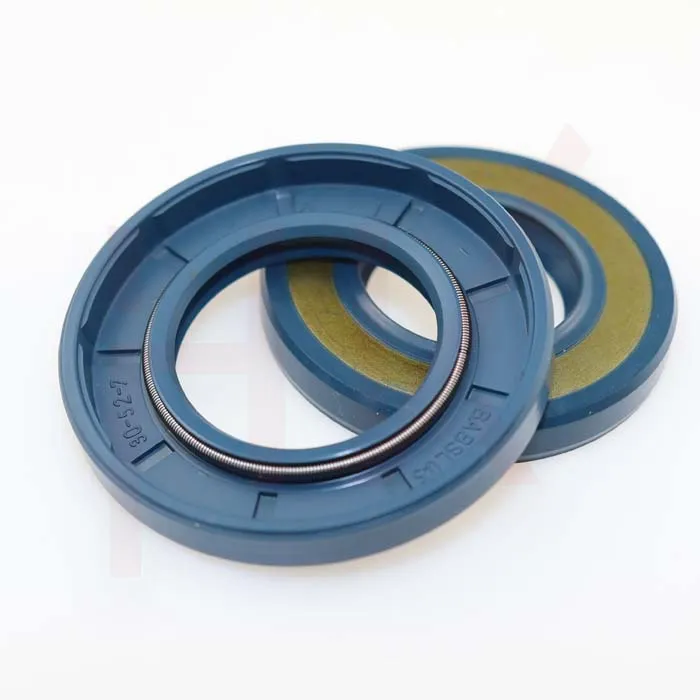

Dust wiper seals are critical components in various mechanical systems, particularly in heavy machinery, automotive applications, and industrial equipment. These seals serve the essential function of keeping contaminants like dust, dirt, and debris out of sensitive components, such as bearings and hydraulic cylinders. Understanding the purpose and design of dust wiper seals can help in maintaining equipment performance and longevity.

What is a Dust Wiper Seal?

A dust wiper seal, often referred to simply as a wiper seal, is a type of sealing device designed to prevent external contaminants from entering the sealed environment. These seals typically consist of an elastomeric material, which provides flexibility and durability, allowing them to conform to the surfaces they protect. The design of a dust wiper seal often includes a lip that contacts the mating surface, creating a barrier against unwanted particles.

Importance of Dust Wiper Seals

1. Protection Against Contaminants One of the primary functions of dust wiper seals is to protect vulnerable components from dirt and dust, which can cause wear and tear. For instance, in hydraulic cylinders, the ingress of dust can lead to premature failure of seals and leakage, negatively impacting the hydraulic system's efficiency.

2. Maintaining Lubrication In systems with moving parts, maintaining a proper lubricant is vital for reducing friction and wear. Dust wiper seals help retain the lubricant by preventing external contaminants from mixing with it, thus extending the life of the machinery.

3. Enhancing Equipment Longevity By protecting against pollutants and optimizing lubrication, dust wiper seals contribute significantly to the overall lifespan of mechanical systems. Regular maintenance and timely replacement of these seals can prevent costly repairs and downtime.

Design Considerations

dust wiper seal

When designing or selecting a dust wiper seal, several factors should be considered

- Material Selection The choice of material for dust wiper seals is crucial. Common materials include nitrile rubber, polyurethane, and silicone. Each material has its properties suited for specific temperature ranges, chemical exposures, and mechanical loads.

- Seal Configuration The shape and profile of the seal determine its effectiveness. Different applications may require variations in seal design, including groove dimensions and wiper lip profiles. Manufacturers often provide custom designs to meet specific operational requirements.

- Operating Conditions Understanding the operating environment is essential for selecting the right dust wiper seal. Factors such as exposure to chemicals, temperature extremes, and humidity levels can influence seal performance.

Maintenance and Replacement

Although dust wiper seals are designed for durability, they can wear out over time. Regular inspections should be part of standard maintenance routines to identify signs of wear, such as cracks, tearing, or loss of elasticity. Addressing these issues promptly can prevent more significant damage to the machinery.

When replacing dust wiper seals, it is essential to choose quality components that match the specifications of the original equipment. Using substandard seals can result in inefficient sealing and increased risk of contamination.

Conclusion

Dust wiper seals are vital components that play a significant role in the efficient operation of mechanical systems. Their ability to prevent contaminants from entering sensitive areas not only protects the integrity of equipment but also enhances performance and longevity. For engineers, operators, and maintenance personnel, understanding the importance and function of dust wiper seals is crucial in ensuring the reliable operation of machinery in various industries. Regular maintenance and careful selection of these seals can lead to significant cost savings and increased operational efficiency.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories