Aug . 19, 2024 04:41 Back to list

Effective Double Lip Oil Seal Solutions for Enhanced Performance and Durability

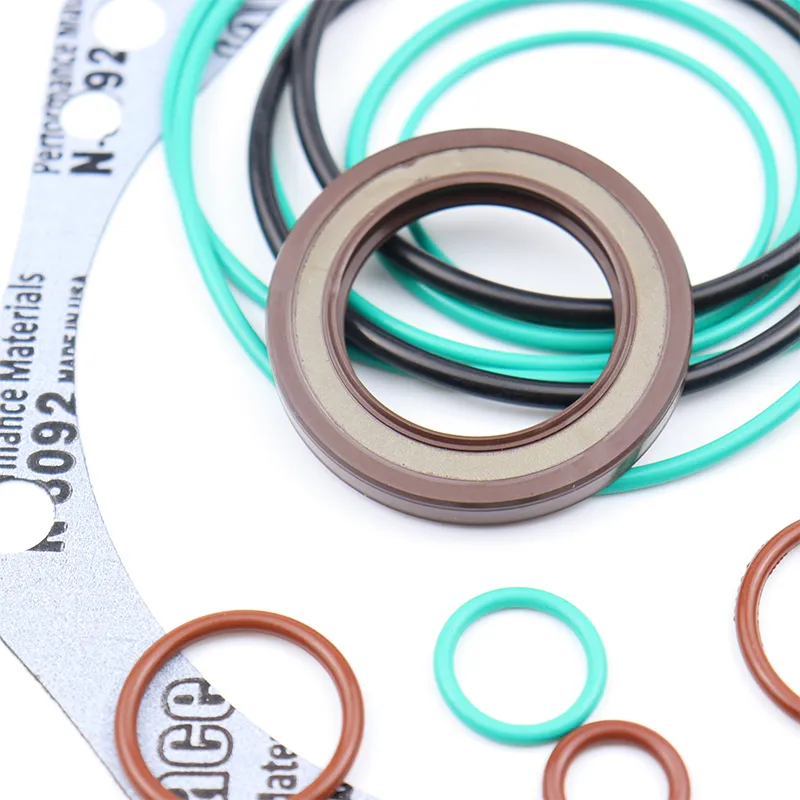

Double Lip Oil Seal An Overview

In the world of mechanical engineering, seals play a critical role in ensuring the efficiency and longevity of machinery. Among various types of seals, the double lip oil seal stands out due to its ability to provide excellent sealing performance in applications involving rotary shafts. This article delves into the design, function, benefits, and applications of double lip oil seals.

Design and Construction

A double lip oil seal consists of a circular elastic rubber lip that is mounted on a metal casing. The seal typically features two sealing lips that face in opposite directions. This unique design enables effective sealing against oil leakage while minimizing the ingress of contaminants, such as dust and water. The metal casing provides structural support, while the elastomeric material is engineered to withstand various operating conditions.

The two lip design creates an effective barrier, where the first lip is primarily responsible for sealing against the oil, ensuring it does not leak out, while the second lip provides an additional line of defense against external contaminants. This redundancy is crucial, especially in applications where equipment is subjected to harsh environments or high levels of wear.

Operating Principles

The functioning of a double lip oil seal is fairly straightforward. When the shaft rotates, the inner surface of the seal makes contact with the shaft. This contact creates a hydrodynamic film that further enhances sealing performance. The pressure difference caused by the motion of the shaft and the surrounding environment ensures that the lip maintains its contact with the shaft, effectively preventing the escape of oil and the entry of foreign particles.

Additionally, the materials used for the lips are often compounded with additives that improve their resilience to heat, abrasion, and chemical exposure. This ensures the seal maintains its integrity and performance over time, even in challenging conditions.

double lip oil seal

Benefits

The double lip oil seal offers several advantages over single lip seals

. First and foremost, the dual sealing action significantly reduces the chances of oil leakage, which can lead to costly fluid losses and environmental hazards. Furthermore, the additional lip acts as a barrier against dirt and moisture, prolonging the service life of the seal and the machinery it protects.Moreover, double lip oil seals are versatile and suitable for a wide range of applications, from automotive to industrial machinery. Their ability to function effectively at varying speeds and pressures makes them an invaluable component in various mechanical systems.

Applications

Double lip oil seals are widely used in numerous fields. In automotive applications, they are commonly found in engines, transmissions, and wheel hubs, where they play a vital role in maintaining fluid integrity. Similarly, in industrial settings, these seals are used in pumps, gearboxes, and compressors, where they protect sensitive internal components from wear and failure.

Additionally, double lip oil seals find their place in agricultural machinery, aircraft, and marine applications, demonstrating their adaptability and importance across various sectors. As industries continue to evolve and seek out more efficient sealing solutions, the demand for high-performance seals like the double lip oil seal is only expected to rise.

Conclusion

In summary, the double lip oil seal is an essential component in many mechanical systems, providing robust sealing solutions that enhance operational efficiency and equipment longevity. Its innovative design and the benefits it offers make it a preferred choice for engineers and manufacturers alike. As technology advances and demands for reliability increase, the continued development and use of double lip oil seals will play a critical role in the future of engineering and manufacturing.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories