Sep . 24, 2024 12:29 Back to list

Dust Wiper Seal Techniques for Improved Equipment Performance and Longevity

Understanding Dust Wiper Seals Importance and Functionality

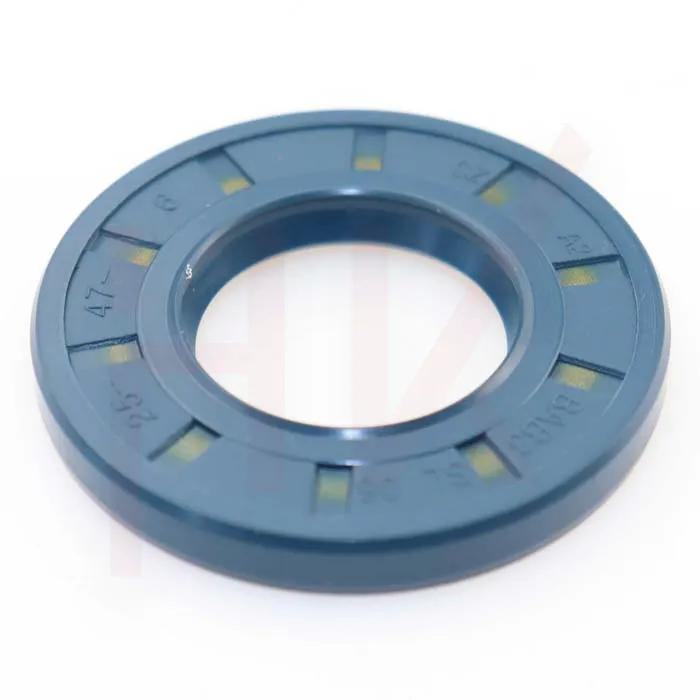

Dust wiper seals, frequently referred to simply as dust seals, play a crucial role in various industrial applications, particularly in hydraulic systems, automotive components, and machinery. Their primary function is to prevent dirt, dust, and other contaminants from entering critical areas that need protection, ensuring optimal performance and longevity of equipment.

What Are Dust Wiper Seals?

Dust wiper seals are specifically designed seals installed at the outermost part of a component or machinery, often acting as the first line of defense against environmental contaminants. Made from durable materials like polyurethane, rubber, or felt, these seals are engineered to endure harsh conditions while providing effective sealing capabilities.

Why Are They Important?

1. Contamination Prevention One of the most significant threats to machinery and hydraulic systems is contamination. Dust and dirt can accumulate over time, leading to wear and damage. Dust wiper seals effectively mitigate this risk by blocking contaminants from entering critical parts, such as hydraulic cylinders, bearings, or piston rods.

2. Enhanced Equipment Longevity By preventing dirt and debris from infiltrating sensitive components, dust wiper seals contribute to the extended lifespan of machinery. This can save organizations money on repairs and replacements, ultimately improving profitability.

dust wiper seal

3. Operational Efficiency Equipment that functions without the interference of contaminants operates more efficiently. Dust wiper seals ensure that machinery runs smoothly, minimizing downtime caused by mechanical failures. As a result, businesses can maintain productivity and meet operational goals more effectively.

4. Reduced Maintenance Costs Regular maintenance is essential for any equipment, but the presence of contaminants can lead to more frequent breakdowns and costly repairs. By utilizing dust wiper seals, businesses can significantly reduce the frequency of maintenance required, thus lowering overall operational costs.

Characteristics of Effective Dust Wiper Seals

When selecting dust wiper seals, it is essential to consider several characteristics to ensure optimal performance

- Material Durability The seal material should be resistant to abrasion, aging, and environmental factors such as temperature fluctuations and chemical exposure. - Design and Fit Effective dust wiper seals must fit snugly in their designated locations to provide a proper seal. The design should allow for easy installation while ensuring complete coverage. - Compatibility The selected seal must be compatible with the equipment it is designed for, ensuring it can withstand the specific operational conditions.

Conclusion

In conclusion, dust wiper seals are indispensable components in the design and maintenance of various machinery and equipment. Their ability to prevent contamination enhances the efficiency and longevity of systems, contributing to reduced maintenance costs and greater operational productivity. By understanding the importance of these seals, businesses can make informed decisions that promote better maintenance practices and improve overall equipment reliability. Investing in high-quality dust wiper seals is a proactive step toward safeguarding the integrity and performance of critical machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories