Nov . 29, 2024 18:32 Back to list

Effective Strategies for Ensuring Dust Sealing in Various Environments and Applications

The Importance of Dust Sealing in Industrial Applications

In various industrial settings, dust control is more than just a cleanliness concern; it plays a critical role in operational efficiency, equipment longevity, and worker health. Dust sealing mechanisms are essential for minimizing the ingress of particulate matter into machinery and work environments, ensuring that systems operate smoothly and safely.

Dust is not merely an inconvenience. The accumulation of dust can lead to significant operational issues. In machinery, dust particles can obstruct moving parts, leading to wear and tear, overheating, and ultimately, equipment failure. This not only results in costly repairs but also leads to unplanned downtime, affecting productivity. For industries such as manufacturing, pharmaceuticals, and food processing, maintaining a clean and controlled environment is vital. This is where effective dust sealing solutions come into play.

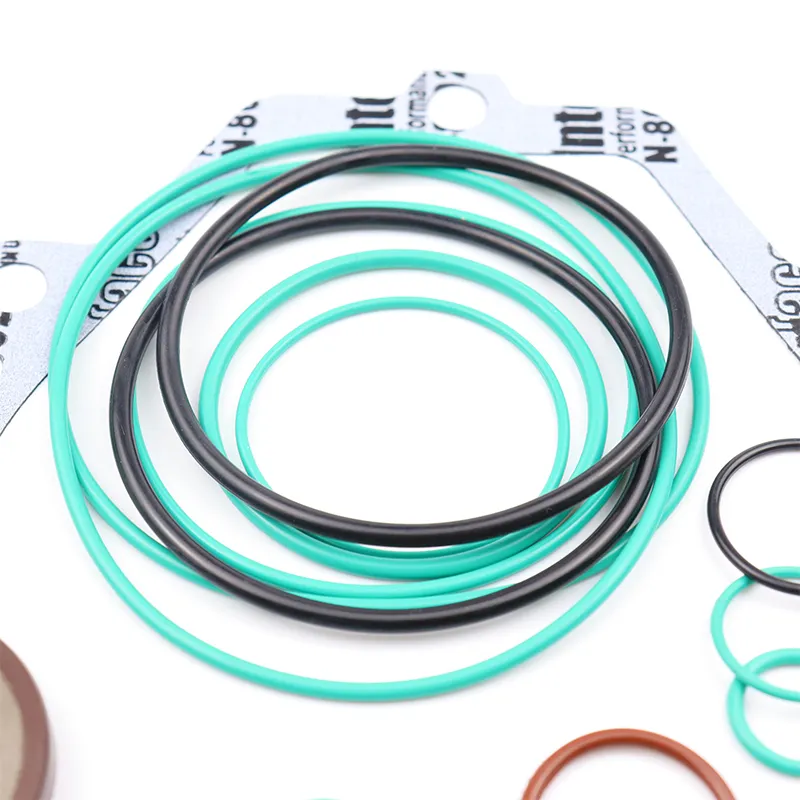

One of the primary functions of dust sealing is to protect sensitive components from contamination. For example, in the electronics industry, dust intrusion can severely impair the function of delicate circuits and components. Dust sealing technologies, such as gaskets, seals, and barriers, are designed to create a protective layer that prevents particles from entering critical areas. Utilizing materials resistant to grease, moisture, and temperature fluctuations enhances the durability and efficacy of these seals.

dust sealing

Moreover, dust sealing has a significant impact on worker safety. High levels of dust can lead to respiratory issues and other health problems for employees. Implementing effective sealing systems helps ensure that work environments are cleaner and safer. This is particularly important in industries dealing with hazardous materials where airborne particles can pose serious health risks.

The design and implementation of dust sealing strategies must be tailored to the specific requirements of each environment. Factors such as the size of the area, type of equipment, and the nature of the dust must be considered. Advanced sealing solutions may include customized enclosures, HEPA filtration systems, and dynamic seals that adjust based on movement or pressure changes.

Furthermore, regular maintenance and inspection of sealing solutions are crucial. Over time, seals can degrade, and their effectiveness may diminish. Establishing a routine maintenance schedule ensures that dust sealing systems continue to operate at peak efficiency.

In conclusion, dust sealing is a fundamental aspect of industrial operations that cannot be overlooked. By investing in effective dust sealing technologies, industries can improve equipment performance, enhance worker safety, and maintain compliance with health and environmental regulations. Ultimately, a robust dust sealing strategy is integral to sustaining productivity and ensuring workplace safety in any operational setting.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories