Dec . 31, 2024 01:15 Back to list

Exploring the Importance of Dust Seals in Mechanical Systems and Equipment Performance

Understanding Dust Seal Importance and Applications in Various Industries

In today’s industrial landscape, maintaining equipment efficiency and prolonging the lifespan of mechanical systems are paramount. One of the essential components contributing to these goals is the dust seal. A dust seal, as the name suggests, is designed to protect machinery and equipment from dust, dirt, and other harmful particulates that can lead to operational failures and increased maintenance costs. This article explores the significance of dust seals, their types, materials, and applications across various industries.

What is a Dust Seal?

A dust seal is a component typically made of rubber or other elastomers that forms a barrier between moving parts and the external environment. It is installed in places where mechanical components such as bearings, rods, and shafts are exposed to particulate contamination. By preventing dust and debris from entering critical areas, dust seals play a crucial role in ensuring the reliability and efficiency of machinery.

Importance of Dust Seals

1. Preventing Contamination One of the primary functions of dust seals is to keep dust and other contaminants out of sensitive machinery. Contamination can lead to wear and tear, corrosion, and ultimately, equipment failure. By ensuring a clean operating environment, dust seals prolong the life of costly components.

2. Reducing Maintenance Costs Regular maintenance is essential for the smooth operation of machines. However, when dust and other particulates infiltrate machinery, the frequency of maintenance increases significantly. Dust seals mitigate this issue, significantly lowering maintenance costs and minimizing downtime.

3. Enhancing Performance Equipment performance can be severely impacted by the presence of contaminants. Dust seals help maintain optimal performance levels by ensuring that lubricants and moving parts are shielded from harmful particulates.

4. Increasing Safety In industries where machinery failure can lead to safety hazards, dust seals are crucial. They help keep equipment operating as intended, thereby minimizing the risk of accidents and protecting worker safety.

Types of Dust Seals

Dust seals come in various types, each designed for specific applications

1. Lip Seals These are common in various machinery applications. They feature a flexible edge or lip that helps create a barrier against dust while allowing for some movement.

2. O-Ring Seals O-ring seals provide a tight seal and are often used in hydraulic systems. They can effectively encapsulate fluids and dust, maintaining system integrity.

3. Radial Seals These seals are typically used in rotating shafts. They are designed to prevent dust from entering the internal mechanism while allowing the shaft to rotate freely.

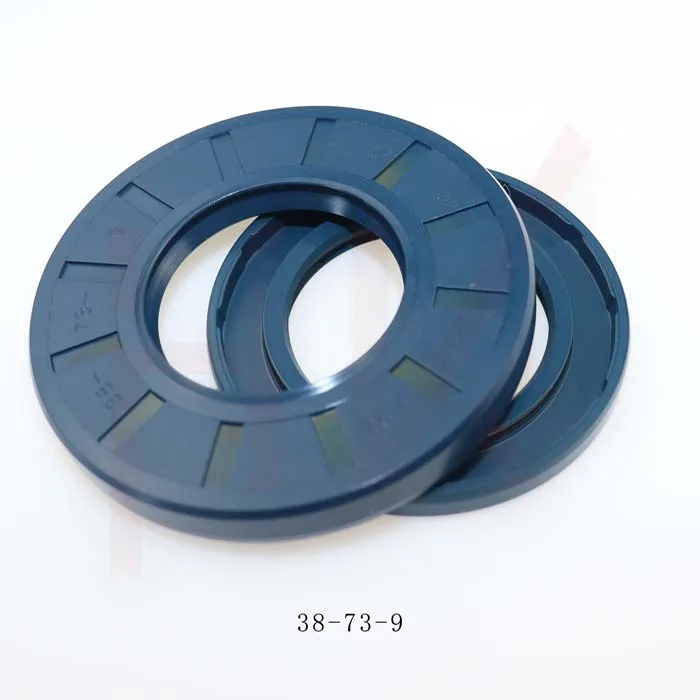

dust seal

4. Mechanical Seals Used in high-pressure applications, mechanical seals provide superior protection against dust and liquids, making them ideal for pumps and compressors.

Materials Used in Dust Seals

The material used for dust seals is vital in determining their effectiveness. Common materials include

- Nitrile Rubber Known for its oil resistance, nitrile rubber is widely used for dust seals in various applications, particularly in automotive and industrial machinery.

- Viton Viton seals are known for their excellent resistance to chemicals and high temperatures, making them ideal for harsh environments.

- Polyurethane This material offers good abrasion resistance and flexibility, which is beneficial in applications where movement occurs.

Applications of Dust Seals

Dust seals find applications across a multitude of industries, including

- Automotive In cars and trucks, dust seals protect bearings, drive shafts, and various mechanical parts from dust and dirt, enhancing vehicle longevity and performance.

- Manufacturing In manufacturing plants, dust seals are critical in machinery to ensure smooth operation and prevent contamination from industrial dust.

- Aerospace High-performance aircraft require utmost reliability, and dust seals play a vital role in ensuring the seals on critical components prevent dust infiltration.

- Construction Equipment used in construction, such as excavators and bulldozers, often operates in dusty environments. Dust seals ensure that hydraulic systems and other mechanical components remain clean and functional.

Conclusion

In conclusion, dust seals are integral to maintaining the efficiency and reliability of machinery in various industries. By preventing contamination, reducing maintenance costs, enhancing performance, and ensuring safety, dust seals contribute significantly to the operational integrity of equipment. As industries continue to evolve and face new challenges, the importance of effective sealing solutions like dust seals will only grow, underscoring their role in modern manufacturing and machinery maintenance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories