Dec . 22, 2024 10:03 Back to list

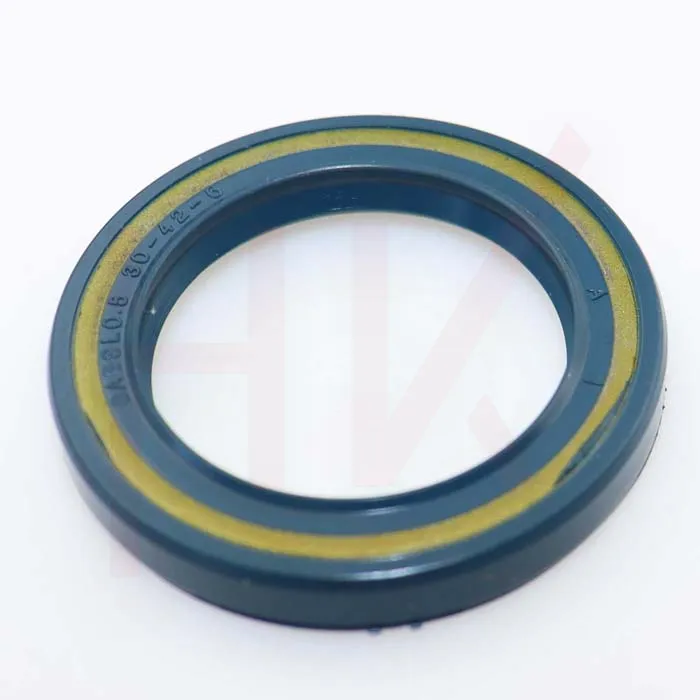

dust proof sealing

The Importance of Dust-Proof Sealing in Modern Applications

In our increasingly technology-driven world, the need for effective dust-proof sealing has never been more critical. Dust can cause significant damage to sensitive equipment, resulting in costly repairs and downtime. Whether in the realms of electronics, automotive, HVAC, or industrial machinery, the role of dust-proof sealing cannot be underestimated. This article delves into what dust-proof sealing is, its applications, and its benefits.

What is Dust-Proof Sealing?

Dust-proof sealing refers to the use of various materials and engineering techniques to create barriers that prevent dust particles from entering a designated area or equipment. The seals are typically made from rubber, foam, silicone, or other synthetic materials that can withstand various environmental conditions. Effective dust-proof seals provide not only protection against dust but also against moisture and other contaminants, enhancing the longevity and reliability of the sealed equipment.

Applications of Dust-Proof Sealing

1. Electronics In the electronics industry, dust-proof seals are paramount for protecting sensitive components such as circuit boards and processors. Dust accumulation can interfere with the operation of electrical connections, leading to short circuits and device failure. Manufacturers often employ dust-proof enclosures and gaskets to ensure that devices remain operational in challenging environments.

2. Automotive The automotive industry utilizes dust-proof sealing in a multitude of ways, from engines to infotainment systems. In vehicles, dirt and dust can jeopardize functionalities and aesthetics. Seals are used around doors, windows, and under the hood to ensure that invasive particles do not compromise the vehicle's performance or passenger comfort.

3. HVAC Systems Dust accumulation within HVAC systems can impair performance and air quality. Dust-proof seals are employed in ductwork, filters, and around mechanical components. These seals help to maintain cleaner air circulation, contributing to healthier indoor environments.

4. Industrial Machinery Heavy machinery in industrial settings is routinely exposed to dust and debris that can disrupt operations. Dust-proof sealing is critical in preserving the integrity of moving parts, electronic sensors, and hydraulic systems. By preventing the ingress of dust, organizations can reduce maintenance costs and prolong equipment life.

dust proof sealing

Benefits of Dust-Proof Sealing

1. Enhanced Equipment Longevity The primary benefit of dust-proof sealing is the extended lifespan of equipment. By preventing dust from infiltrating sensitive areas, the wear and tear on components are significantly reduced, leading to fewer failures and repairs.

2. Improved Performance Dust can interfere with the operation of machines and electronics, leading to inefficiencies and increased energy consumption. Dust-proof sealing helps ensure that equipment operates at optimum efficiency, saving organizations both energy and money.

3. Health and Safety In sectors such as food production or pharmaceuticals, maintaining a dust-free environment is essential for health and safety standards. Dust-proof seals help in adhering to regulations by keeping the working environment clean and free from contaminants.

4. Cost Savings Although investing in quality dust-proof sealing may seem like an added expense, the long-term savings from reduced downtime, lower maintenance costs, and improved efficiency make it a wise investment. Companies that overlook this aspect often face higher operational costs due to equipment failures and inefficiencies.

5. Versatility Dust-proof seals can be custom-made to fit various applications and environments. Whether for use in extreme temperatures, corrosive environments, or outdoor settings, there is a seal available that can meet specific needs.

Conclusion

In conclusion, the significance of dust-proof sealing spans multiple industries and applications. As technology continues to advance and the demand for durability and reliability increases, the importance of effective dust-proof sealing will only grow. Not only does it protect equipment and enhance operational efficiency, but it also contributes to health and safety through cleaner environments. Investing in proper dust-proof sealing solutions is not just a matter of convenience; it is essential for sustaining the performance and longevity of modern-day technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories