Dec . 05, 2024 11:09 Back to list

Effective Solutions for Dust Proof Sealing in Industrial Applications

The Importance of Dust Proof Sealing in Modern Products

In today's technologically advanced world, the performance and longevity of devices and equipment have become crucial factors in consumer choice. One of the significant aspects that contribute to the durability and reliability of these products is dust proof sealing. This article explores the importance of dust proof sealing, its applications, and the technology behind it.

Understanding Dust Proof Sealing

Dust proof sealing refers to the design features and materials used to prevent dust, dirt, and other particulate matter from entering a product. This is especially pertinent for devices that operate in environments prone to contaminants, such as industrial settings, outdoor locations, and even homes. Dust can damage internal components, hamper functionality, and lead to a shortened lifespan of products, making effective sealing paramount.

Applications of Dust Proof Sealing

Dust proof sealing is crucial in various sectors and applications

. Here are some prominent areas where it plays a vital role1. Consumer Electronics Smartphones, tablets, and laptops often incorporate dust sealing to protect sensitive components like circuit boards and batteries. Manufacturers like Apple and Samsung have made significant strides in increasing the dust and water resistance of their devices, achieving ratings such as IP67 and IP68.

2. Industrial Equipment In industries such as manufacturing and construction, equipment is frequently exposed to dust and debris, which can impair machinery operation. Dust proof sealing in mechanical equipment, power tools, and safety gear not only ensures functionality but also enhances worker safety by reducing the risk of malfunctions caused by contaminants.

3. Automotive Industry Cars are equipped with various electronic systems that require protection from dust. Sealing in areas like the engine compartment, dashboard, and electronic control units is essential for maintaining performance and reliability over time.

4. Medical Devices In the healthcare sector, medical instruments and devices need to be kept free from contaminants to ensure patient safety. Dust proof sealing helps maintain a sterile environment, which is especially vital in surgical instruments and diagnostic equipment.

5. Home Appliances From vacuum cleaners to air purifiers, household appliances benefit from effective dust sealing to enhance performance and reduce wear and tear.

dust proof sealing

The Technology Behind Dust Proof Sealing

The effectiveness of dust proof sealing depends largely on the choice of materials and design techniques. Several methods are used to achieve this, including

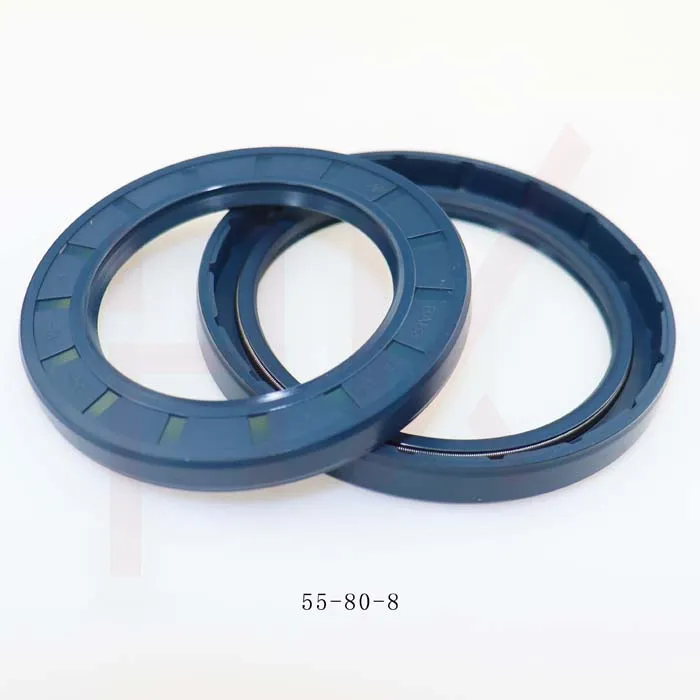

- Gaskets and O-rings These components are often made from rubber or silicone, providing a flexible barrier that can compress and conform to surfaces, preventing the ingress of dust.

- Molded Seals Involving precision molding techniques, these seals are designed to fit exactly into the contours of a device, offering improved reliability compared to traditional gaskets.

- Coatings Some manufacturers utilize advanced coatings that repel dust and dirt, creating a barrier on surfaces that can be easily cleaned.

- Enclosures Fully enclosed designs shield internal components from external elements. Innovative designs that incorporate breathability can also allow for heat dissipation while keeping dust out.

Challenges and Future Innovations

While dust proof sealing is essential, it is not without challenges. Achieving a balance between sealing effectiveness and the need for ventilation or user accessibility can be complex. Additionally, as technology progresses, devices are becoming increasingly compact, making it more challenging to integrate effective sealing solutions.

Looking forward, research and innovation in materials science will likely lead to the development of more sophisticated sealing techniques. Advances in nanotechnology and smart materials could yield even better performance in dust proofing, making devices more resilient and easier to maintain.

Conclusion

Dust proof sealing is a critical aspect of product design that enables devices across various industries to function effectively in challenging environments. As consumer expectations for durability and performance continue to rise, the importance of innovative sealing solutions will only grow. Manufacturers must invest in effective sealing technologies to ensure that their products not only meet but exceed user demands for reliability and performance, paving the way for a future where dust is no longer a threat to our modern conveniences.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories