Dec . 05, 2024 14:33 Back to list

dust lip seal

Understanding Dust Lip Seals Importance and Functionality

In various industrial applications, ensuring the integrity and longevity of machinery is paramount. Among the myriad components that contribute to this goal, one often overlooked yet critical element is the dust lip seal. Dust lip seals play a fundamental role in protecting equipment from contaminants, thereby enhancing operational efficiency and extending the life of machinery. This article will explore the importance, functionality, and applications of dust lip seals in various industries.

What is a Dust Lip Seal?

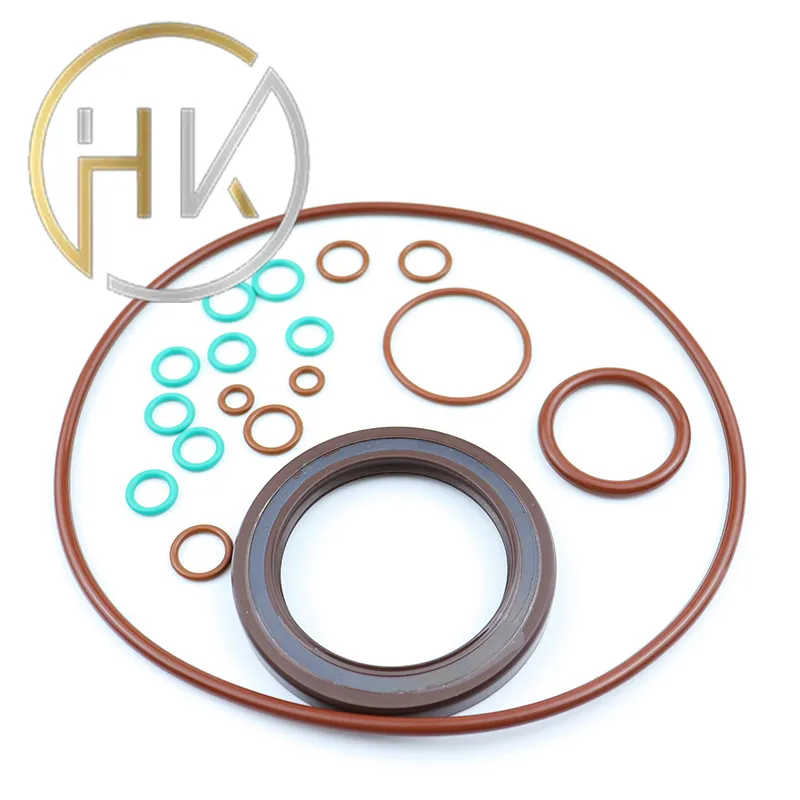

A dust lip seal is a mechanical seal designed to prevent dirt, dust, moisture, and other contaminants from entering sensitive areas of machinery. Typically made from elastomers, such as rubber or polyurethane, these seals feature a flexible lip that comes into contact with a rotating shaft or a static surface, creating a barrier against external elements. Dust lip seals are often found in conjunction with other sealing mechanisms, such as oil seals, to provide comprehensive protection for rotating shafts, hydraulic cylinders, and other applications susceptible to contamination.

Importance of Dust Lip Seals

1. Contamination Prevention The primary function of a dust lip seal is to prevent dust and debris from infiltrating sensitive components. Contaminants can cause abrasive wear on mechanical parts, leading to premature failure. By effectively sealing these areas, dust lip seals help maintain the integrity of machinery.

2. Cost Efficiency The wear and tear caused by contaminants can lead to increased maintenance costs and equipment downtime. Dust lip seals mitigate these issues by protecting critical components, ultimately resulting in significant cost savings over time. Businesses can avoid costly repairs and extend the service life of their machinery.

3. Enhanced Performance When equipment is free from contaminants, it operates more efficiently. Dust lip seals contribute to optimal performance by ensuring that machinery remains clean and free from potential blockages or damage caused by foreign particles. This improved functionality can lead to higher productivity and better outcomes in manufacturing processes.

How Dust Lip Seals Work

Dust lip seals function through the unique design of their sealing lips. When the shaft rotates, the dynamic sealing lip adapts to the surface, creating a tight seal that prevents the ingress of dust and debris. The flexibility of the lip allows for a certain degree of movement while maintaining contact with the shaft, ensuring that the seal remains effective even as the components experience wear and tear over time.

dust lip seal

Moreover, many dust lip seals are designed with an additional lip or barrier that provides an extra layer of protection. This design can help divert contaminants away from the primary sealing surface, further enhancing the longevity and effectiveness of the seal.

Applications of Dust Lip Seals

Dust lip seals are utilized across various industries, including automotive, aerospace, construction, and manufacturing. Some common applications include

- Automotive Industry In vehicles, dust lip seals are used in wheel bearings, transmission systems, and shock absorbers to protect against road dust and moisture, ensuring smooth operation and durability.

- Construction Equipment Heavy machinery used in construction often operates in harsh environments. Dust lip seals are critical for protecting hydraulic cylinders and pivot points from dirt, mud, and debris, enabling reliable performance.

- Aerospace In the aerospace industry, dust lip seals are integral to maintaining the integrity of various components, including landing gear and control systems, where contamination can pose serious safety risks.

- Manufacturing Conveyor systems and industrial machinery frequently employ dust lip seals to ensure that moving parts remain clean and functional, enhancing overall productivity.

Conclusion

In conclusion, dust lip seals are vital components that serve a crucial purpose in protecting machinery from environmental contaminants. Their ability to prevent dust, dirt, and moisture from infiltrating sensitive areas contributes significantly to the longevity and efficiency of various industrial applications. By investing in high-quality dust lip seals, businesses can ensure their equipment operates smoothly, reduce maintenance costs, and ultimately achieve a higher level of productivity. As industries continue to evolve, the importance of recognizing and understanding the role of dust lip seals will undoubtedly remain paramount.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories