Dec . 02, 2024 03:30 Back to list

dust lip seal

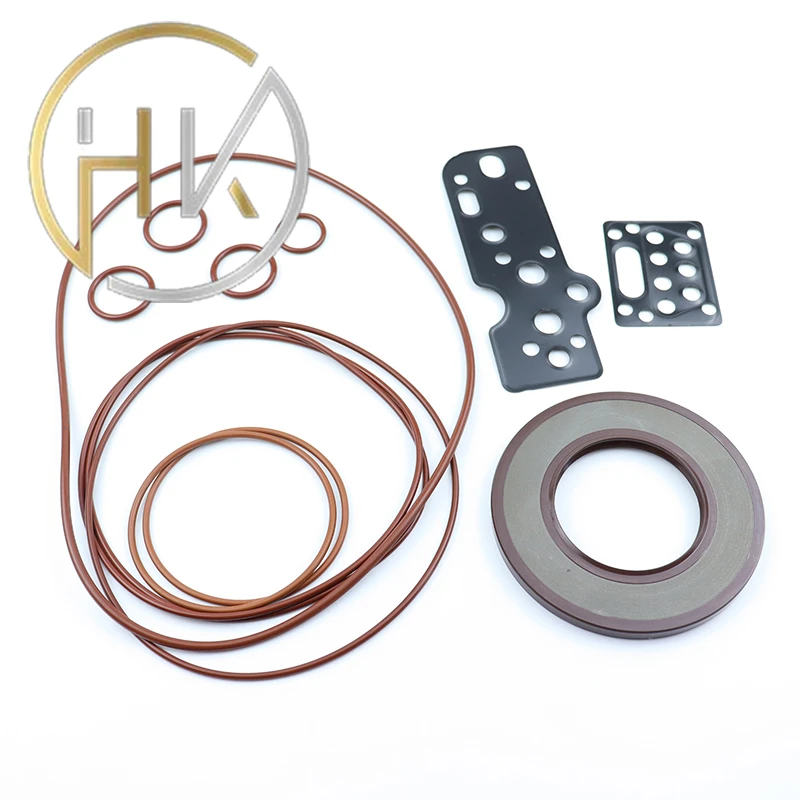

Understanding Dust Lip Seals An Essential Component in Mechanical Systems

In the realm of mechanical engineering, the importance of effective sealing systems cannot be overstated. Among the various types of seals available, dust lip seals play a crucial role in protecting machinery from contaminants and ensuring operational efficiency. This article will explore the construction, function, advantages, and applications of dust lip seals, while highlighting their significance in various industries.

What Are Dust Lip Seals?

Dust lip seals, also known as dust seals, are designed to prevent the ingress of dust, dirt, and other contaminants into machinery. They are typically composed of flexible materials, such as rubber or thermoplastic, which provide a reliable barrier against particulate matter. The seal consists of a primary sealing lip that contacts the shaft or housing surface and a secondary lip that acts as a dust barrier, preventing contaminants from reaching critical internal components.

Construction and Design

The design of dust lip seals often incorporates features that enhance their effectiveness. The primary sealing lip is usually constructed to accommodate rotation and axial movement, allowing the seal to ensure contact with the shaft while adapting to any misalignments. The secondary dust lip extends outward, forming a shield that guards against larger particles and debris. This dual-lip configuration is essential for maintaining the integrity of the seal over time, as it minimizes wear and prolongs the lifespan of the sealing system.

Different materials are utilized in the crafting of dust lip seals, depending on the application's specific requirements. Common materials include nitrile rubber, silicone, and polyurethane, each offering different levels of resistance to temperature fluctuations, chemicals, and abrasion. The choice of material plays a vital role in determining the seal's effectiveness and longevity.

Functionality and Advantages

dust lip seal

The primary function of dust lip seals is to maintain a clean operating environment for machinery. Contaminants can lead to increased wear and tear on components, resulting in equipment failure and costly downtime. Dust lip seals help mitigate these issues by providing a robust barrier, thus ensuring that lubricants remain contained and functioning optimally.

One significant advantage of dust lip seals is their relatively simple design, which allows for easy installation and maintenance. They can be integrated into various machinery without extensive modifications, making them an economical choice for manufacturers and service providers. Moreover, dust lip seals are versatile and can be utilized in a wide range of applications, from automotive engines to industrial machinery.

Applications Across Industries

Dust lip seals are employed across numerous industries, including automotive, construction, aerospace, and manufacturing. In automotive applications, they are commonly found in wheel bearings, suspension systems, and drive shafts, where they protect sensitive components from dirt and moisture. In industrial settings, dust lip seals safeguard gearboxes, hydraulic cylinders, and conveyor systems, ensuring that the equipment operates smoothly and efficiently.

Additionally, the aerospace industry relies on dust lip seals to protect critical systems from extreme environmental conditions. The ability of these seals to withstand varying temperatures and pressures is vital for maintaining the integrity of aerospace components.

Conclusion

In summary, dust lip seals play an integral role in the protection and longevity of mechanical systems. Their ability to prevent the intrusion of dust and other contaminants safeguards critical components, thereby enhancing operational efficiency and reducing maintenance costs. As industries continue to evolve and machinery becomes more complex, the significance of effective sealing solutions, such as dust lip seals, will only increase. For engineers, manufacturers, and maintenance professionals, understanding the functionalities and advantages of dust lip seals is essential in ensuring the reliability and performance of their equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories