Nov . 16, 2024 06:01 Back to list

dust lip seal

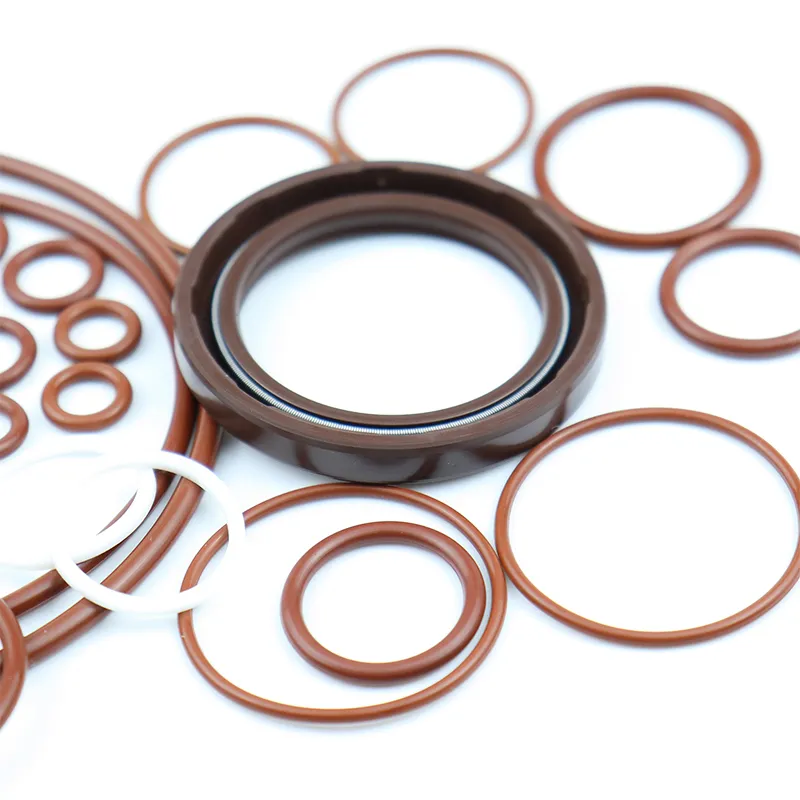

Understanding Dust Lip Seals Their Importance and Applications

In the world of machinery and equipment, effective sealing solutions are crucial for maintaining operational efficiency and prolonging the lifespan of components. Among various sealing technologies, dust lip seals have gained considerable attention due to their unique design and functionality. This article explores the significance of dust lip seals, their working principles, applications, and the benefits they offer across different industries.

What are Dust Lip Seals?

Dust lip seals, often referred to as dust seals or dust shields, are a specific type of sealing device designed to prevent the ingress of dust, dirt, and other contaminants into rotating assemblies. They often accompany other sealing elements, such as oil seals, to provide a robust barrier against not only dust but also moisture and other harmful substances.

Typically made from rubber or polymer materials, dust lip seals feature a flexible lip that makes contact with the shaft or housing. This design allows the lip to deflect contaminants while maintaining a tight seal against external pressures. The effectiveness of these seals lies in their ability to accommodate variations in the shaft's position while still providing excellent sealing performance.

Working Principle

The operation of dust lip seals revolves around their geometry and materials. The flexible lip creates a contact seal during rotation, conforming to the surface of the shaft or housing. This contact is crucial as it prevents dust and debris from penetrating the system.

Dust lip seals also incorporate a specific design that allows them to work efficiently even in challenging environments. For example, the lip’s angle and material hardness can be tailored for different applications—softer materials may be used for more delicate assemblies, while harder compounds might suit rugged conditions. Additionally, some dust seals may feature auxiliary sealing components to enhance their protective capabilities.

Applications of Dust Lip Seals

Dust lip seals find applications in a broad range of industries, including

1. Automotive Industry In vehicles, dust lip seals protect bearings and other critical components from dirt and moisture. They are commonly found in wheel hubs, transmissions, and engine assemblies, ensuring reliable performance and reducing maintenance needs.

2. Industrial Machinery Heavy machinery, such as excavators and bulldozers, operates in environments laden with dust and debris. Dust lip seals in these applications safeguard vital components against dirt, prolonging equipment life and enhancing performance.

dust lip seal

3. Aerospace In aircraft, dust lip seals play a significant role in maintaining the integrity of hydraulic systems and preventing contamination that could lead to critical failures.

4. Electronics In electronics manufacturing, preventing ingress of dust is paramount to maintaining product quality. Dust lip seals are used in various devices to ensure that internal components remain protected during assembly and use.

5. Agricultural Equipment Farm machinery often operates in dust-heavy environments. Dust lip seals help protect key parts from sand and soil, facilitating smoother operations and reducing downtime.

Benefits of Dust Lip Seals

Dust lip seals offer numerous advantages, including

- Enhanced Protection By preventing the ingress of contaminants, dust lip seals extend the life of bearings, shafts, and other components, reducing replacement costs and operational downtime.

- Improved Performance With contaminants kept at bay, the overall efficiency and functionality of machinery and equipment are improved. This leads to better performance in terms of speed and reliability.

- Versatility Dust lip seals can be customized regarding size, material, and design to suit specific industrial needs, making them a versatile solution for numerous applications.

- Cost-Effectiveness Investing in high-quality dust lip seals can result in significant savings by minimizing maintenance needs and preventing costly repairs related to contamination.

Conclusion

In conclusion, dust lip seals are crucial components in various industries, offering effective protection against dust and other contaminants. Their unique design, combined with their adaptability to different applications, ensures that machinery and equipment operate efficiently and reliably. As industries continue to evolve, the importance of robust sealing solutions, such as dust lip seals, will only increase, making them an indispensable part of modern engineering practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories