Nov . 12, 2024 13:00 Back to list

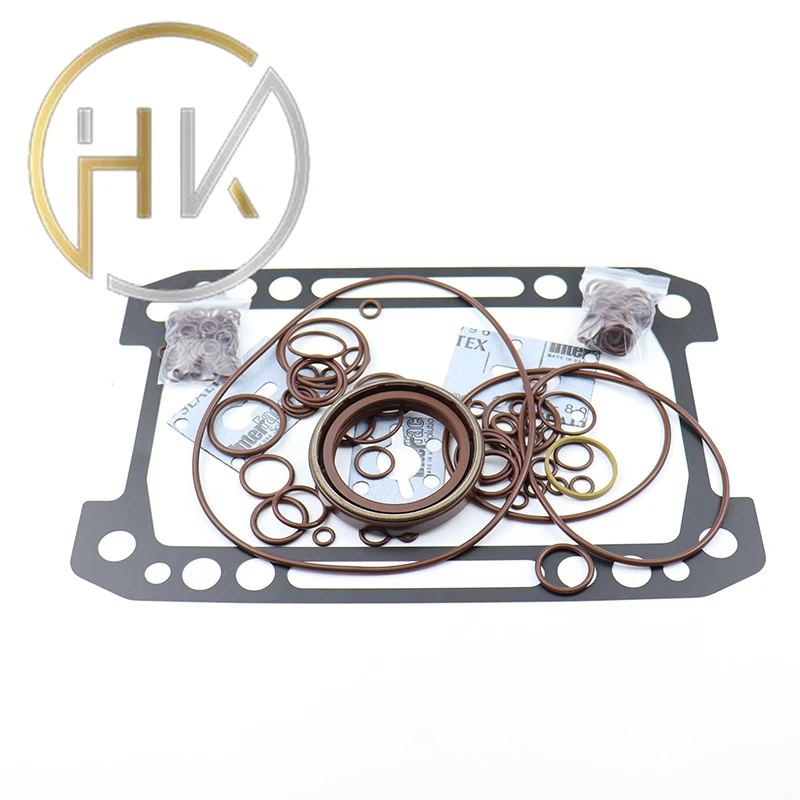

dust lip seal

Understanding Dust Lip Seals Importance, Functionality, and Applications

In various industrial applications, the performance and longevity of machines often depend on their sealing components. One such crucial component is the dust lip seal. These seals play a pivotal role in protecting equipment from dust, dirt, moisture, and other contaminants that can potentially compromise operational efficiency and lead to premature wear of critical components.

What is a Dust Lip Seal?

A dust lip seal, often referred to simply as a lip seal, is a type of mechanical seal that consists of a rubber or elastomeric lip and a metal casing. The design is intended to create a barrier against the ingress of external contaminants while allowing for the necessary movement of machine parts. Dust lip seals are typically utilized in rotating shafts, such as those found in bearings, pumps, and various rotating machinery.

The primary purpose of these seals is to keep the internal components of machinery protected from harmful debris and to retain lubricants within the system. This dual functionality ensures smooth operations and minimal friction, which helps in prolonging the life of the equipment.

How Dust Lip Seals Work

Dust lip seals function through their innovative design that incorporates a flexible lip. When installed, the lip makes contact with the surface of the rotating shaft, creating a seal that prevents the ingress of dust and other particulates. The lip is designed to exert a certain amount of radial force against the shaft to maintain a tight seal, yet it is flexible enough to accommodate slight misalignments or variations in shaft size.

The effectiveness of dust lip seals can be attributed to the materials used in their construction. Typically made from synthetic rubber compounds, these seals can be engineered to withstand various environmental conditions, including temperature fluctuations and exposure to chemicals. The materials are chosen for their durability, flexibility, and ability to resist wear and tear over time.

The Importance of Dust Lip Seals

dust lip seal

1. Contaminant Protection The primary function of dust lip seals is to protect critical components and lubricants from dust and debris, which can lead to wear and tear. Keeping contaminants out is vital in ensuring the longevity of machinery.

2. Lubrication Retention These seals help to retain lubrication within the machinery, ensuring that moving parts operate smoothly and efficiently. This not only enhances performance but also reduces the chances of mechanical failure due to insufficient lubrication.

3. Cost Efficiency By extending the lifespan of the equipment and reducing the need for frequent repairs or replacements, dust lip seals contribute to overall cost savings for businesses. Minimizing downtime and maintenance plays a significant role in improving productivity.

4. Versatility Dust lip seals are designed to suit various applications, from automotive to industrial machinery. Their adaptability makes them a preferred choice in many sectors, including manufacturing, construction, and transportation.

Applications of Dust Lip Seals

The applications for dust lip seals are extensive. Here are a few key areas where they are commonly used

- Automotive In vehicles, dust lip seals are used in wheel bearings, driveshafts, and gearboxes to protect against road debris and moisture. - Industrial Machinery These seals are employed in applications ranging from conveyor systems to heavy machinery, where dust and dirt exposure is prevalent. - Agricultural Equipment Dust lip seals protect the moving parts of tractors and harvesters from soil and other contaminants. - Aerospace In aircraft, dust lip seals are vital for maintaining the integrity of various components in harsh environments.

Conclusion

In summary, dust lip seals are essential components of many mechanical systems, serving critical functions that enhance performance, protect against contaminants, and ensure operational efficiency. Their versatility and effectiveness make them indispensable in a wide range of applications, from everyday automotive uses to complex industrial machinery. Understanding the importance of these seals is crucial for anyone involved in equipment maintenance and design, as their role is fundamental in achieving reliability and durability in machine operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories