Oct . 13, 2024 03:16 Back to list

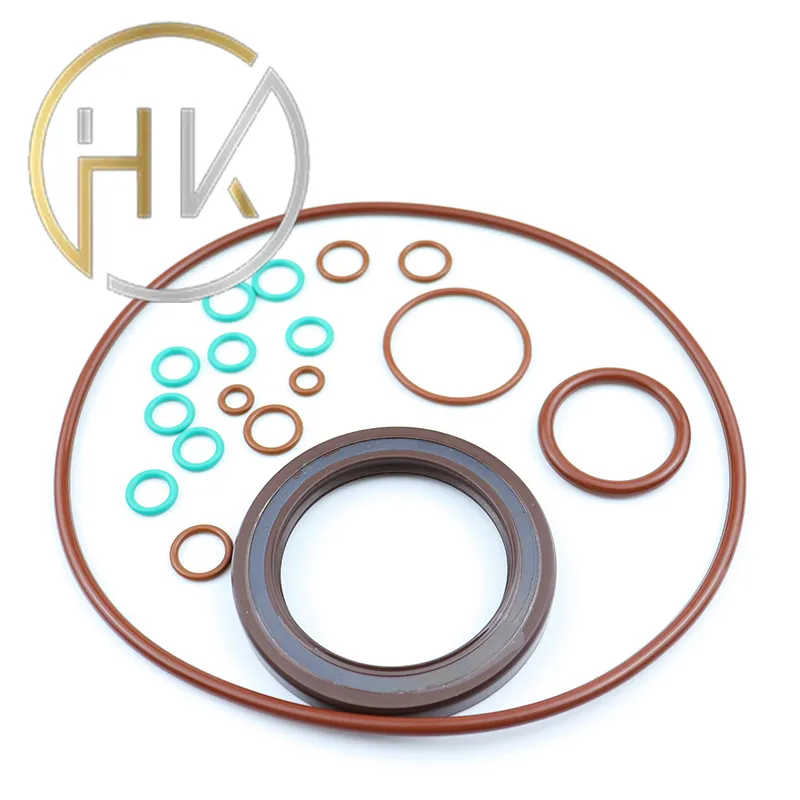

dual loader cylinder seals

Understanding Dual Loader Cylinder Seals A Comprehensive Overview

Dual loader cylinder seals are integral components in various hydraulic and pneumatic systems, playing a vital role in ensuring efficient operation and longevity of equipment. These seals are designed to enhance the sealing capacity of loading cylinders, which are often used in heavy machinery and industrial applications for smooth and reliable operation.

The primary function of dual loader cylinder seals is to prevent fluid leakage between the moving parts of a cylinder. Fluid leakage can lead to decreased efficiency, increased operational costs, and potential damage to machinery. The dual design of these seals allows for enhanced sealing performance, creating a barrier that effectively isolates the fluid from the external environment. This not only improves the sealing integrity but also reduces wear on the cylinder walls, leading to longer service life.

Constructed from advanced materials such as polyurethane, nitrile, or PTFE, dual loader cylinder seals are designed to withstand harsh operating conditions, including extreme temperatures and pressures. The choice of material is critical, as it influences the seal's ability to resist abrasion, chemical exposure, and other potential hazards. By selecting the appropriate material for specific applications, engineers can optimize performance and reliability.

dual loader cylinder seals

The installation of dual loader cylinder seals requires careful consideration to ensure proper alignment and compression. An improperly installed seal can lead to premature failure or inefficient operation. Therefore, it is essential for maintenance personnel to be trained in the correct installation techniques and to inspect seals regularly for signs of wear or damage.

One of the notable advantages of dual loader cylinder seals is their versatility. They can be used in various applications, including construction equipment, agricultural machinery, and manufacturing heavy equipment. This adaptability makes them a preferred choice in industries where hydraulic systems are prevalent.

In conclusion, dual loader cylinder seals are a crucial component in maintaining the functionality and efficiency of hydraulic and pneumatic systems. They offer improved sealing performance, durability, and versatility, making them indispensable in multiple industrial applications. Regular maintenance and proper installation practices can further enhance their lifespan and operational efficiency. Understanding and utilizing these seals effectively can lead to significant improvements in machinery performance and reduction in operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories