Dec . 11, 2024 09:41 Back to list

Understanding Double Lip Seals for Enhanced Performance and Durability in Mechanical Applications

The Double Lip Seal An Essential Component in Sealing Technology

In various industrial applications, the integrity of seals plays a crucial role in ensuring efficient performance and longevity of machinery. Among the diverse range of sealing solutions, the double lip seal stands out for its distinctive design and functionality. This article will explore the characteristics, applications, advantages, and maintenance implications of double lip seals.

Understanding Double Lip Seals

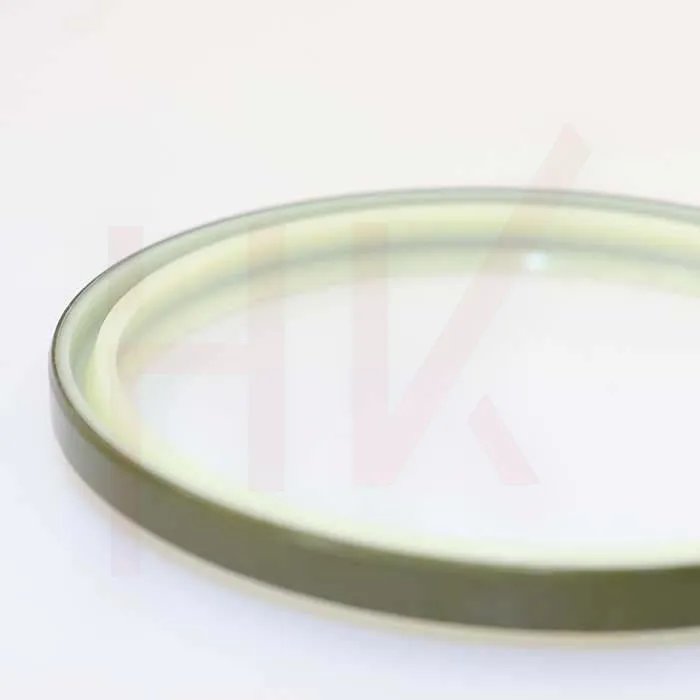

A double lip seal consists of two flexible sealing lips that are designed to work in tandem to provide enhanced sealing capabilities. The structure typically comprises a robust outer casing made from materials such as rubber, polymer, or metal, which houses the two lips. These lips are strategically placed so that they can effectively seal against contaminants and fluids while allowing for flexibility and movement.

The design of a double lip seal offers improved performance over single lip seals. The first lip acts as a primary barrier against dirt, dust, and moisture, while the second lip serves as a secondary barrier, enhancing sealing reliability. This dual-layer configuration helps to significantly reduce the risk of leakage and prolongs the lifespan of the component being sealed.

Applications of Double Lip Seals

Double lip seals are versatile and can be found in a variety of applications across different industries, including

1. Automotive Industry Double lip seals are commonly used in automotive configurations such as wheel hubs, transmission systems, and engine components. Their ability to withstand harsh conditions, coupled with effective sealing against lubricants and contaminants, makes them ideal for automotive uses.

2. Aerospace In the aerospace sector, reliability is paramount. Double lip seals are employed in aircraft engines and landing gear assemblies to maintain pressure and prevent fluid leakage, ensuring safety and operational efficiency.

3. Industrial Machinery Heavy equipment and industrial machinery often rely on double lip seals for their hydraulic and pneumatic systems. These seals protect against contaminants that could disrupt machine performance.

double lip seal

4. Household Appliances Everyday devices, from washing machines to refrigerators, utilize double lip seals to prevent leaks and manage pressure, assuring that appliances function properly and efficiently.

Advantages of Double Lip Seals

Several benefits make double lip seals a preferred choice among engineers and manufacturers

1. Enhanced Sealing Performance The dual-lip configuration provides superior sealing capability, effectively blocking contaminants and maintaining the integrity of the sealed environment.

2. Reduced Risk of Leakage The redundant sealing provided by a double lip system minimizes the chances of leaks, which can be detrimental in various applications, particularly those involving hazardous or high-value fluids.

3. Extended Lifespan With better sealing performance and reduced wear due to the protective nature of two lips, double lip seals tend to have a longer life cycle than single lip seals.

4. Versatile Material Options Double lip seals can be manufactured from various materials, allowing for customization based on the specific requirements of the application, such as temperature resistance and compatibility with different substances.

Maintenance Considerations

While double lip seals are designed for durability, regular maintenance is essential to ensure their optimal performance. Operators should routinely inspect seals for signs of wear, deformation, or contamination. Over time, environmental factors can lead to degradation, so proactive replacement of seals at intervals recommended by manufacturers is advised.

In conclusion, double lip seals are pivotal in sealing technology, providing essential protection and performance across numerous industries. Their unique design, coupled with significant advantages over traditional seals, establishes them as a reliable choice for maintaining operational integrity in various mechanical applications. As technology advances and industries demand more efficient solutions, the significance of components like the double lip seal will only continue to grow.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories