Dec . 15, 2024 21:18 Back to list

double lip oil seal

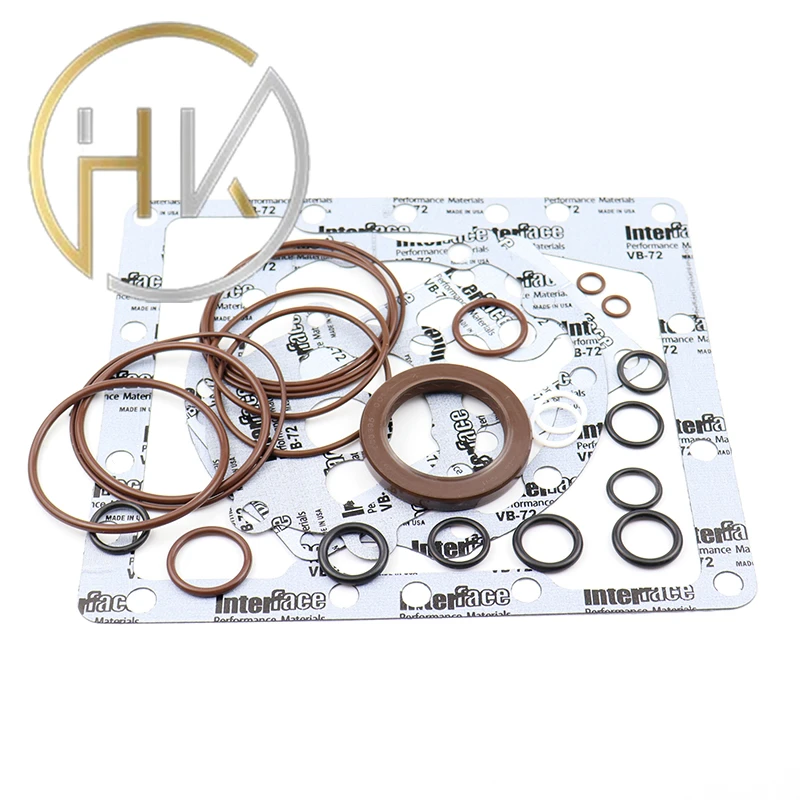

Understanding Double Lip Oil Seals Functionality and Importance

Double lip oil seals, commonly referred to as double lip seals or simply oil seals, are essential components in various machinery and automotive applications. Their primary function is to prevent lubrication oil from leaking out of the system while also keeping contaminants like dirt, dust, and moisture from entering. This dual action is critical for maintaining efficient operation and prolonging the life of machinery.

Construction of Double Lip Oil Seals

A double lip oil seal typically consists of a robust outer casing and two flexible sealing lips made from elastomeric materials such as rubber or synthetic compounds. The outer casing is designed to fit snugly into the housing, providing a secure shield against external elements. The two lips create two barriers, effectively enhancing sealing capability. This design allows for improved lubrication retention and better contaminant exclusion compared to single lip seals.

The materials used in the construction of these seals are carefully selected to withstand various operational challenges. They must resist not only the oil but also temperature fluctuations, chemical exposure, and wear from friction. Advanced materials like nitrile, fluorocarbon, or polyurethane are commonly employed, depending on the specific application requirements.

Applications of Double Lip Oil Seals

Double lip oil seals find their use across a wide range of industries. In automotive applications, they are crucial in engine components, transmission systems, and drive axles. They ensure that the oil used for lubrication remains contained, thereby maintaining optimal performance while protecting engine parts from potential damage due to leakage.

In industrial machinery, double lip oil seals are employed in hydraulic systems, pumps, and gearboxes

. Their ability to prevent contamination is vital, as any ingression of foreign particles can lead to significant operational issues and increased maintenance costs. Moreover, these seals help in conserving energy by reducing friction losses, which can translate into better fuel efficiency and lower operating costs.double lip oil seal

Advantages of Double Lip Oil Seals

The double lip design offers several advantages over traditional single lip seals. One of the primary benefits is their enhanced sealing performance. The two lips work together to create a more effective barrier against oil leaks and contaminants, making them ideal for applications where reliability is paramount.

Additionally, double lip seals provide better adaptability to working conditions. They can accommodate misalignments and shaft deflections more effectively, which can be particularly beneficial in situations where equipment endures vibrations or changes in load. This flexibility ensures a longer lifespan for the seal and reduces the frequency of replacements, thus lowering operational costs.

Maintenance and Replacement

While double lip oil seals are designed for durability, they still require regular inspection and maintenance. Signs of wear, such as visible cracks or deformation, can indicate that a replacement is necessary. It is crucial to address these issues promptly, as failing to do so can lead to oil leaks and catastrophic damage to machinery.

When replacing double lip oil seals, it is vital to ensure the correct size and compatibility with the application. Using an incorrectly sized seal can lead to premature failure, negating the benefits that double lip seals offer.

Conclusion

In conclusion, double lip oil seals are a fundamental component in various mechanical systems, significantly contributing to machinery reliability and longevity. Their advanced design offers a superior sealing solution, making them an indispensable element in automotive and industrial applications alike. Regular maintenance and timely replacement will ensure that these seals continue to perform effectively, safeguarding the integrity of the machinery in which they are installed. Understanding the role and advantages of double lip oil seals can lead to better maintenance practices and improved operational efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories