Dec . 14, 2024 01:50 Back to list

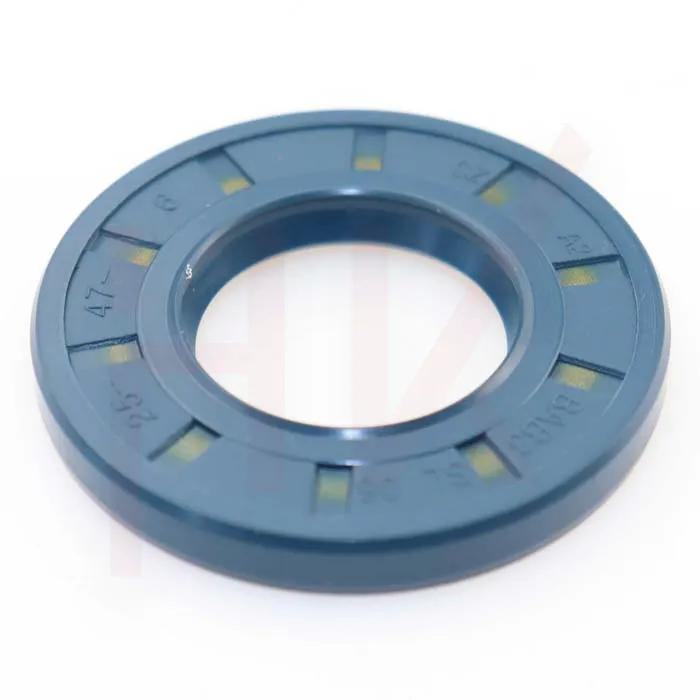

cylinder oil seal

Understanding Cylinder Oil Seals An Essential Component in Mechanical Systems

In mechanical engineering, the efficiency and longevity of machinery largely depend on various components working seamlessly together. Among these critical elements is the cylinder oil seal, a small yet vital component that plays a pivotal role in the operation of countless machines, particularly in engines and hydraulic systems. This article explores the functionality, types, applications, and best practices for maintaining cylinder oil seals.

What is a Cylinder Oil Seal?

A cylinder oil seal, also known as a rotary shaft seal, is designed to prevent the leakage of lubricant—usually oil—from the cylinder of an engine or a hydraulic system. It also safeguards the system against the intrusion of contaminants such as dust, dirt, moisture, or other foreign particles. Operating under variable pressures and temperatures, oil seals help maintain the required lubrication in moving parts, thereby reducing friction and wear, and enhancing the efficiency and reliability of the machinery.

Functionality of Oil Seals

The primary function of a cylinder oil seal is to provide a barrier that keeps oil contained within the cylinder while preventing external contaminants from entering. The seal consists of a flexible lip made of rubber or synthetic materials, which makes contact with the shaft or cylinder wall. As the shaft rotates, the lip forms a tight seal that holds the lubricant in place, ensuring smooth operation.

During operation, the lip of the seal deforms slightly, creating a more effective seal as the pressure changes. This design allows for minimal friction against the rotating shaft while maintaining a robust seal against leaks. The effectiveness of the seal is crucial in preventing oil loss, which can lead to diminished performance and increased wear on components.

Types of Cylinder Oil Seals

Cylinder oil seals come in various types to accommodate different applications and operating conditions. The most common types include

1. U-shaped Seals Ideal for static applications, these seals can contain fluids but are not designed for high-speed rotary use. 2. Single Lip Seals Commonly used in hydraulic cylinders and light-duty applications, these seals feature a single sealing lip for effective containment of oil.

cylinder oil seal

3. Double Lip Seals Equipped with two sealing lips, double lip seals provide enhanced protection against contamination, making them suitable for more demanding applications.

4. Spring-Loaded Seals These seals incorporate a spring mechanism to maintain contact with the shaft, which helps to adapt to wear and tear over time, thereby prolonging the service life of the seal.

Applications of Cylinder Oil Seals

Cylinder oil seals are utilized across a wide range of applications, including

- Automotive Engines They help keep engine oil contained while preventing dust and debris from entering, which is critical for optimal engine performance. - Hydraulic Systems In hydraulic cylinders, oil seals maintain hydraulic pressure and prevent fluid leaks, ensuring efficient operation. - Industrial Machinery Used in various industrial equipment, oil seals help to prevent contamination and oil loss, contributing to the overall efficiency of manufacturing processes.

Maintenance and Best Practices

To ensure the longevity and effectiveness of cylinder oil seals, regular inspection and maintenance are essential. Here are some best practices

- Inspection Check for signs of wear, such as cracks or deformation in the seal material. - Proper Installation Ensure seals are installed correctly to avoid misalignment and undue stress, which can lead to premature failure. - Lubrication Apply light grease to the seal lips during installation to reduce friction and enhance performance. - Monitoring Regularly monitor fluid levels and signs of leakage to address potential issues before they escalate.

Conclusion

Cylinder oil seals are indispensable components in modern machinery, playing a crucial role in maintaining the efficiency and longevity of various systems. Understanding their functionality, types, and maintenance practices is vital for anyone involved in mechanical design or maintenance. By ensuring that cylinder oil seals are properly selected and maintained, operators can significantly enhance the performance and reliability of their equipment, ultimately leading to improved productivity and reduced costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories