Dec . 22, 2024 02:10 Back to list

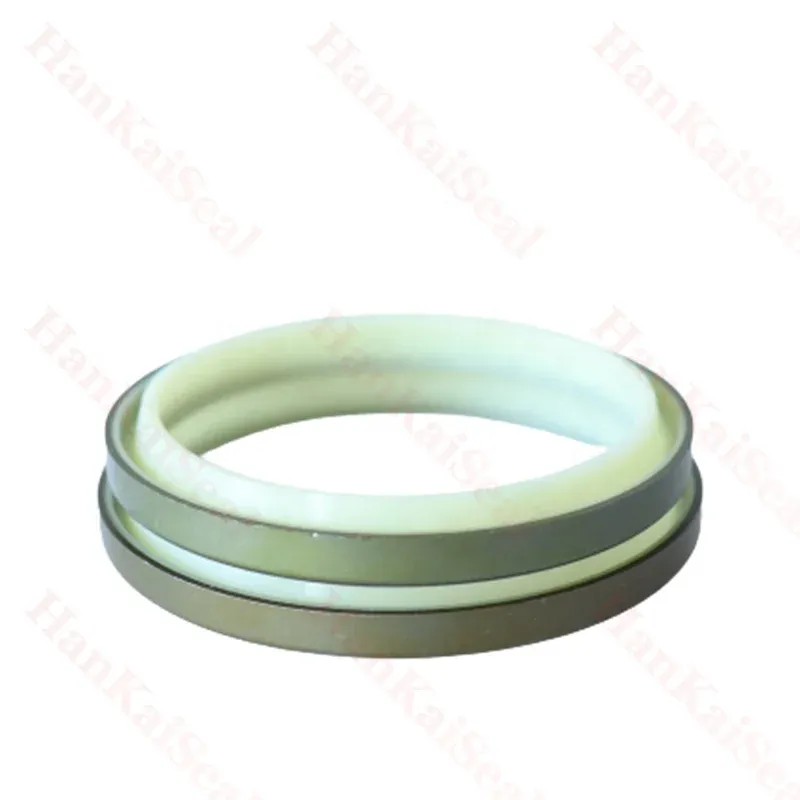

custom oil seals

The Importance of Custom Oil Seals in Modern Machinery

Oil seals are an essential component in a wide range of machinery, ensuring the proper functioning and longevity of various mechanical systems. Among the myriad of seals available in the market, custom oil seals hold a significant advantage for industries that require tailored solutions to meet specific operational requirements. This article delves into the significance of custom oil seals, their benefits, applications, and considerations for businesses in need.

Understanding Oil Seals

Oil seals, also known as lip seals, play a critical role in preventing the leakage of lubricants from machinery while simultaneously protecting against the ingress of contaminants and dirt. They typically consist of a flexible sealing lip, which is pressed against a rotating shaft, and a metal or elastomeric body that holds the lip in place. The performance of oil seals can greatly influence the efficiency of mechanical systems, reducing wear and tear, minimizing friction, and ultimately prolonging the lifespan of the equipment.

The Need for Customization

While standard oil seals are suitable for many applications, there are instances where off-the-shelf solutions fall short. Equipment and machinery come in various shapes and sizes, each with unique operational environments. Custom oil seals offer a solution by tailoring the dimensions, materials, and design to meet specific needs.

For instance, equipment operating under extreme temperatures or corrosive environments may require seals made from specialized materials such as fluorocarbon or silicone rubber, which can withstand harsh conditions. Additionally, the dimensions may need to be altered to accommodate specific shaft sizes or housing configurations that cannot be found in standard seals.

Benefits of Custom Oil Seals

1. Enhanced Performance Custom oil seals can improve the overall performance of machinery by ensuring a precise fit, thereby minimizing leakage and reducing the risk of contamination. This leads to increased efficiency and less energy loss in the system.

2. Reduced Downtime By tailoring the seals to specific applications, businesses can mitigate the risks of premature seal failure. This, in turn, reduces the frequency of maintenance and repair, leading to decreased downtime and higher productivity.

3. Cost-Effectiveness Although custom oil seals might have a higher initial investment than standard options, their durability and superior performance often translate to long-term savings. Reduced maintenance costs and enhanced machinery reliability are significant factors that contribute to the cost-effectiveness of custom solutions.

4. Versatility Custom oil seals can be designed for a wide range of applications, from automotive and aerospace to industrial machinery and agricultural equipment. This versatility makes them a preferred choice for manufacturers looking for adaptable sealing solutions.

Applications of Custom Oil Seals

custom oil seals

Custom oil seals find applications in various industries, demonstrating their importance in modern machinery

. Some common applications include- Automotive Industry In vehicles, custom oil seals are utilized in engines, transmissions, and differentials. They ensure that vital lubricants remain contained, which is essential for optimal performance.

- Aerospace Aircraft systems operate under extreme conditions, making the use of customized seals critical for ensuring safety and reliability.

- Industrial Machinery Manufacturing equipment often requires specific seal designs to operate efficiently. Customized oil seals help in maintaining the integrity of machinery in these demanding environments.

- Agricultural Equipment Custom seals are essential in farm machinery to prevent lubricant loss and ensure that equipment operates smoothly in sometimes harsh outdoor conditions.

Considerations for Custom Oil Seal Procurement

When seeking custom oil seals, businesses must consider several factors

1. Material Selection The choice of material will depend on the operational environment, including temperature extremes and exposure to chemicals.

2. Design Specifications Accurate specifications are crucial for ensuring a proper fit. This includes the shaft diameter, housing dimensions, and the desired sealing characteristics.

3. Supplier Expertise Partnering with a reputable manufacturer that specializes in custom oil seals is vital. Their expertise can aid in selecting the right design and material for the intended application.

Conclusion

Custom oil seals are indispensable components for businesses seeking reliability and performance in their machinery. By offering tailored solutions that address specific operational needs, these seals not only enhance machinery functionality but also drive down long-term costs. As industries continue to evolve, the importance of custom oil seals in maintaining mechanical integrity will only grow, making them a fundamental aspect of modern engineering.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories