Dec . 05, 2024 11:43 Back to list

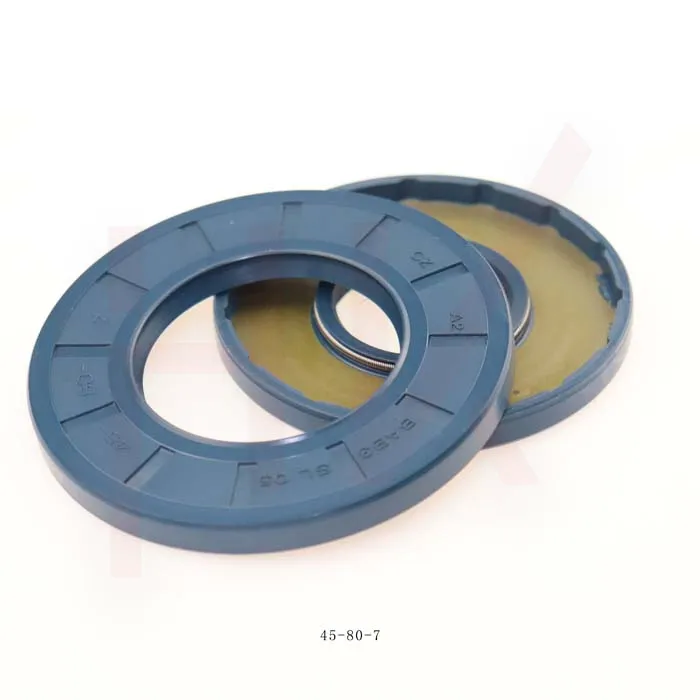

custom oil seals

The Importance of Custom Oil Seals in Modern Engineering

In the ever-evolving world of engineering and manufacturing, the role of custom oil seals cannot be overstated. These vital components are designed to prevent the leakage of fluids and keep contaminants out of mechanical systems, thereby ensuring the efficiency and longevity of machinery. This article delves into the significance of custom oil seals, the materials used in their production, and the diverse applications across various industries.

Understanding Oil Seals

Oil seals, often referred to as sealing rings, are mechanical devices utilized to contain lubricants within machines while preventing the ingress of dirt, dust, and other external contaminants. They are typically made from materials like rubber, silicone, or thermoplastics, which provide flexibility, durability, and resistance to various environmental factors. While standard oil seals are widely available, custom oil seals offer tailored solutions that meet specific operational requirements.

The Need for Customization

In many industrial applications, standard oil seals may not suffice due to unique machinery designs or specific operational conditions. Custom oil seals are crafted to fit particular dimensions, shapes, and performance criteria. They can be designed to withstand extreme temperatures, high pressures, aggressive chemicals, or other demanding environments.

Customization ensures that the oil seals provide an optimal fit, thereby minimizing the risk of fluid leaks and enhancing overall system performance. Moreover, custom solutions can lead to longevity improvements, as appropriately designed seals reduce wear and tear on both the seals themselves and adjacent components.

Materials Used in Custom Oil Seals

The choice of material for manufacturing custom oil seals is crucial, as it directly affects the seal's performance and compatibility with the fluids it is intended to contain

. Common materials include1. Nitrile Rubber (NBR) Excellent for general-purpose sealing applications, NBR offers good resistance to petroleum oils and grease. It is widely used in automotive and industrial machinery.

2. Fluoroelastomer (FKM) Known for its superior resistance to high temperatures and aggressive chemicals, FKM is often used in aerospace and chemical processing industries.

custom oil seals

3. Silicone Flexible and capable of withstanding extreme temperatures, silicone oil seals are ideal for applications that demand high-performance sealing over a wide temperature range.

4. Polyurethane Highly durable and resistant to abrasion, polyurethane seals are commonly utilized in demanding applications, such as heavy machinery and hydraulic systems.

Applications of Custom Oil Seals

The versatility of custom oil seals makes them applicable across a wide range of industries, including

- Automotive Custom oil seals prevent leaks in engines, transmissions, and differentials, ensuring performance and reliability.

- Aerospace High-performance seals in aircraft systems protect against extreme temperatures and pressures, contributing to the safety and efficiency of flight operations.

- Manufacturing Custom seals play a critical role in various machinery, from conveyor systems to pumps, helping maintain operational integrity.

- Oil and Gas In exploration and production, custom oil seals are essential for preventing leaks in drilling equipment and pipelines, thus ensuring safety and environmental protection.

Conclusion

Custom oil seals represent a crucial component in maintaining the efficiency and reliability of machinery across various sectors. Their tailored design and selection of materials lead to enhanced performance, reduced risks of leakage, and prolonged lifespan for mechanical systems. As industries continue to evolve and demand higher standards of performance, the importance of custom oil seals will only grow, solidifying their role as indispensable components in modern engineering. Investing in quality custom oil seals is not merely a decision but a strategic move toward operational excellence and sustainability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories