Sep . 14, 2024 22:22 Back to list

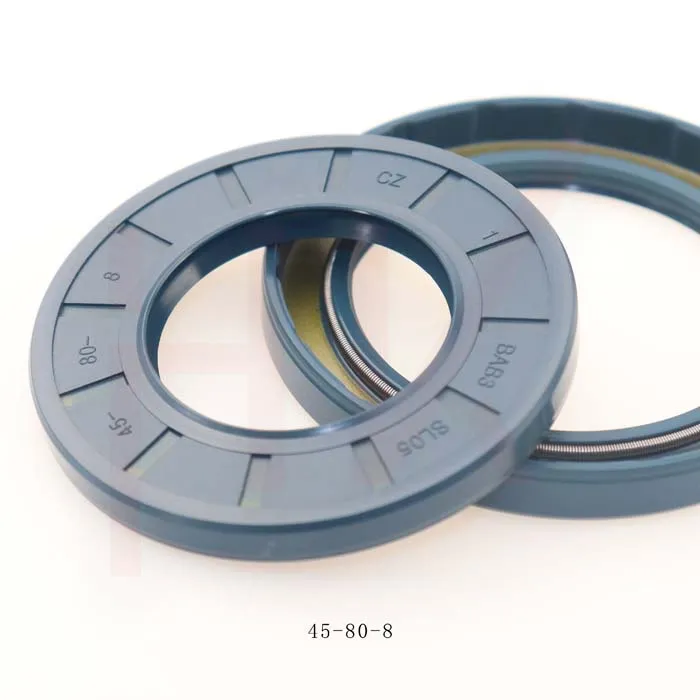

custom oil seals

The Importance of Custom Oil Seals in Modern Engineering

Oil seals, often referred to as lip seals, play a crucial role in various mechanical systems by preventing lubricant leakage and protecting against contaminants. In industries where precision and reliability are paramount, custom oil seals emerge as an essential component tailored to meet specific application requirements. This article explores the significance of custom oil seals, their manufacturing processes, and the factors to consider when selecting them.

Understanding Custom Oil Seals

Custom oil seals are designed to fit specific dimensions and operational conditions of machinery, ensuring optimal performance. Unlike standard oil seals, which may not meet the unique needs of every application, custom seals are engineered for particular tasks. These seals can be manufactured from various materials, including rubber, polyurethane, and silicone, depending on the operating environment, temperature, and pressure requirements.

Manufacturing Process

The manufacturing of custom oil seals involves several key steps. First, engineers conduct in-depth analyses to determine the required specifications, including size, shape, and material properties. This often includes examining factors such as the type of fluid contained, temperature ranges, and exposure to chemicals or environmental conditions.

Once specifications are finalized, prototyping begins. Advanced techniques like 3D printing and CAD (Computer-Aided Design) software play a significant role in creating prototypes that accurately represent the final product. Testing prototypes for durability, flexibility, and temperature resistance is crucial before moving to mass production.

After successful testing, the final design is set for production. Quality control is paramount in this phase, ensuring that each seal meets industry standards and is free from defects. Custom oil seals are then delivered to clients, ready for integration into their systems.

custom oil seals

Key Considerations When Choosing Custom Oil Seals

1. Material Selection The choice of material is critical, as it can greatly influence the seal's performance. Factors such as temperature resistance, chemical compatibility, and wear resistance should guide material selection.

2. Size and Dimensions Accurate measurement is essential. Seals must fit perfectly within the designated space to prevent leakage and ensure functionality.

3. Operating Conditions Consider the environment in which the seal will operate. High temperatures, pressure variations, and exposure to chemicals can all impact the seal's performance.

4. Expected Lifespan Understanding the expected lifespan of the equipment will help determine the type of seal required. Some applications may necessitate seals designed for longer durability.

5. Cost vs. Performance While custom solutions can be more expensive than off-the-shelf options, the potential for reduced downtime and equipment failure can make them a more cost-effective choice in the long run.

Conclusion

Custom oil seals play an indispensable role in ensuring the reliability and efficiency of machinery across various industries. By catering to specific application requirements, they help prevent fluid leakage, protect against contaminants, and enhance overall operational performance. As technology and manufacturing processes continue to evolve, the ability to produce high-quality custom oil seals will only strengthen their significance in modern engineering. Whether in automotive, aerospace, or industrial applications, investing in the right custom oil seal can lead to significant improvements in performance and longevity.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories