Jul . 29, 2024 00:37 Back to list

Comprehensive Seal Kit for 3 Ton Hydraulic Jacks Ensuring Reliable Performance and Durability

Understanding the Importance of a 3-Ton Hydraulic Jack Seal Kit

Hydraulic jacks are essential tools commonly used in various industries, including automotive, construction, and manufacturing, to lift heavy loads safely and efficiently. A 3-ton hydraulic jack is particularly useful for lifting vehicles, heavy machinery, and other substantial objects. However, like any mechanical tool, these jacks can experience wear and tear over time, particularly in their seals. This is where a 3-ton hydraulic jack seal kit becomes invaluable.

The Role of Seals in Hydraulic Jacks

The seal in a hydraulic jack serves a critical function it prevents hydraulic fluid from leaking out of the cylinder while ensuring that the pressure is maintained within the system. This is crucial for the jack's performance, allowing it to lift loads effectively and safely. If the seals wear down or become damaged—often due to exposure to extreme temperatures, contaminants, or simply the passage of time—the jack can lose hydraulic fluid, leading to reduced lifting capacity or even complete failure.

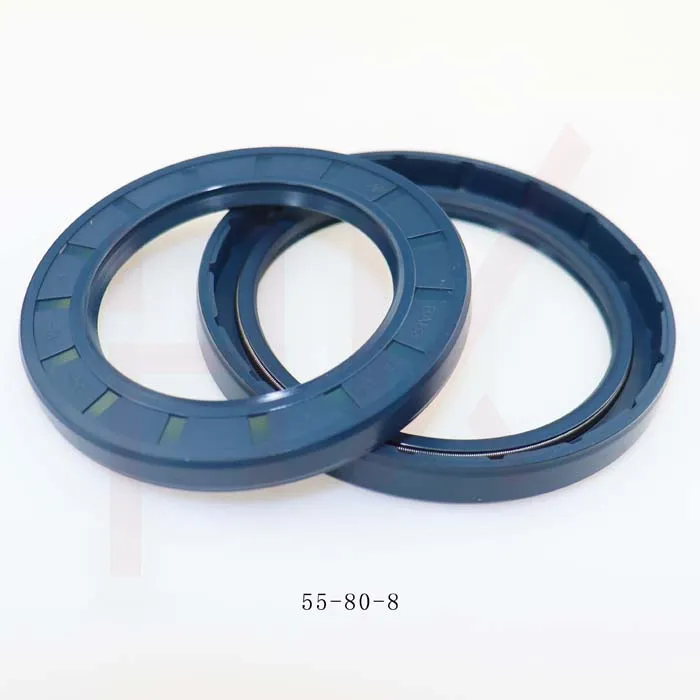

A 3-ton hydraulic jack seal kit typically contains all the necessary components to replace the worn seals in your hydraulic jack. This might include O-rings, backup rings, and various other seals that are specifically designed to fit the unique design of a 3-ton jack.

Benefits of Using a Seal Kit

1. Cost-Effective Maintenance Purchasing a seal kit is significantly cheaper than replacing the entire hydraulic jack. By investing in a seal kit, users can extend the lifespan of their equipment and avoid the cost associated with premature replacement.

2. Improved Safety Worn seals can lead to hydraulic fluid leaks, which can be hazardous. Maintaining proper seal integrity ensures that your hydraulic jack operates safely and effectively, reducing the risk of accidents in the workshop or job site.

3. Enhanced Performance By replacing worn seals with those from a seal kit, users can restore the original lifting power of their hydraulic jacks. This ensures that the jack can lift its rated capacity without issues.

3 ton hydraulic jack seal kit

4. Easy Installation Most seal kits are designed for straightforward installation, even for those who may not be highly skilled in mechanical work. Many kits come with instructions, making it accessible for DIY enthusiasts and professionals alike.

How to Select the Right Seal Kit

When looking for a 3-ton hydraulic jack seal kit, it’s crucial to ensure that the kit is compatible with your specific jack model. Factors to consider include

- Compatibility Always check the model and brand of your hydraulic jack to ensure you select a seal kit designed for it.

- Quality of Materials Look for kits made from high-quality materials that can withstand hydraulic fluid types and operating conditions.

- Reviews and Recommendations Research reviews from other users to gauge the reliability and effectiveness of a seal kit. This can provide invaluable insight into long-term performance.

Conclusion

Maintaining a 3-ton hydraulic jack is essential for ensuring safe and efficient operation. A hydraulic jack seal kit serves as a crucial investment for extending the life of the jack, improving its performance, and ensuring safety during lifting operations. By understanding the importance of seals in hydraulic systems and promptly addressing any wear and tear, users can maximize the effectiveness of their equipment. Whether you're a professional mechanic, a construction worker, or a DIY enthusiast, a good quality seal kit is an essential addition to your toolkit.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories