Jul . 29, 2024 21:46 Back to list

Comprehensive Guide to Choosing the Right Pump Seal Kit for Your Needs and Applications

Understanding Pump Seal Kits Essential Components for Pump Maintenance

In the realm of industrial machinery, pumps play a vital role in transporting fluids across various applications. To ensure the smooth operation of pumps, one must pay close attention to their maintenance and repair—one critical aspect of which involves the use of pump seal kits. This article delves into what pump seal kits are, their components, benefits, and the importance of regular maintenance.

What is a Pump Seal Kit?

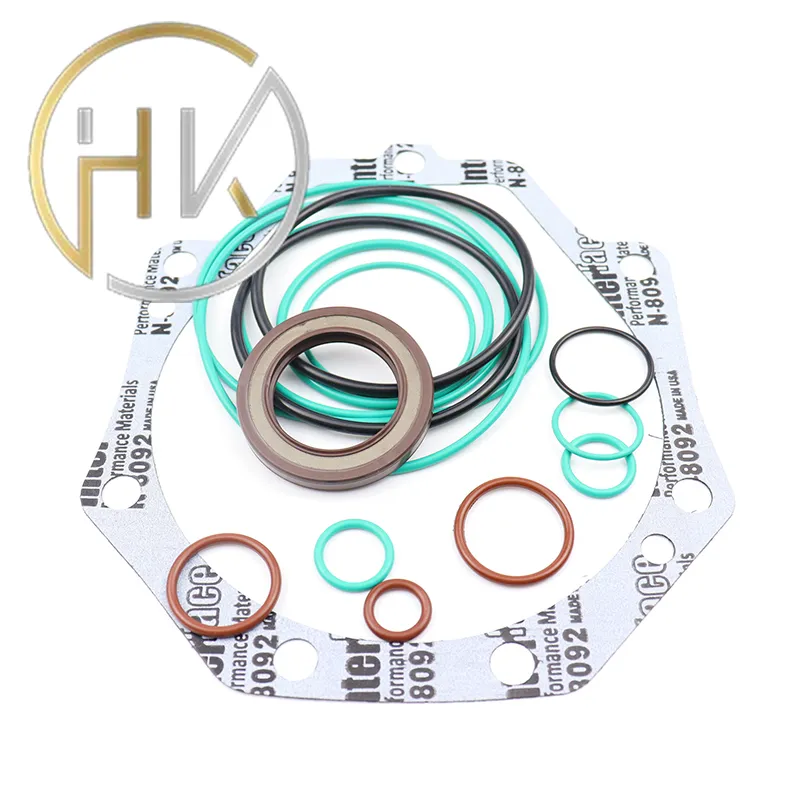

A pump seal kit is a collection of components designed to replace worn or damaged seals within a pump. Seals are crucial for preventing leaks and ensuring the efficient operation of the pump. The seal kit typically includes various types of seals—such as rotary seals, mechanical seals, and O-rings—as well as necessary accessories like lubricants and installation tools. Each kit is tailored to specific pump models and applications, ensuring a perfect fit for optimal performance.

Components of a Pump Seal Kit

1. Rotary Seals These seals help to maintain a fluid barrier between the pump's rotating shaft and housing. They are essential in preventing leakage of the pumped fluid, particularly in applications involving high speeds and pressures.

2. Mechanical Seals Often used in centrifugal pumps, mechanical seals consist of two main parts—a stationary part and a rotating part. These seals create a tight seal that minimizes the risk of fluid leakage through the shaft.

3. O-Rings These circular seals are indispensable in several applications, serving to fill the gaps between two parts and preventing fluid escape. Their design allows them to withstand varying levels of pressure and temperature.

4. Lubricants Many seal kits include lubricants that facilitate smooth installation and prolong the lifespan of seals by reducing friction and wear.

5. Installation Tools Some kits even come with specialized tools to aid in the proper replacement of seals, ensuring that the installation process is efficient and effective.

pump seal kit

Benefits of Using Pump Seal Kits

Utilizing pump seal kits presents numerous advantages

- Cost Efficiency Regularly replacing seals with a seal kit can prevent more significant issues that might require costly repairs or even pump replacement. Preventive maintenance is often more economical than reactive measures.

- Enhanced Performance Fresh seals allow for optimal fluid containment and flow, ensuring that the pump operates at maximum efficiency.

- Simplicity Many seal kits come with detailed instructions, making the replacement process straightforward. This accessibility empowers maintenance staff to perform repairs with minimal downtime.

- Improved Reliability Regular maintenance using seal kits enhances the reliability of the pumps, reducing the likelihood of unexpected failures that can disrupt operations.

Importance of Regular Maintenance

Neglecting the maintenance of pumps can lead to severe consequences, such as decreased efficiency, increased energy consumption, and, ultimately, system failures. Regular inspection and replacement of seals using pump seal kits play a critical role in the overall health of pumping systems. It is advisable to adhere to a routine maintenance schedule, monitoring the condition of seals and addressing issues before they escalate.

In conclusion, pump seal kits are integral to the successful operation and longevity of pumps across various applications. By facilitating easy repair and maintenance, these kits contribute to the reliability and efficiency of pump systems. Investing in quality seal kits and adhering to regular maintenance schedules can significantly enhance operational performance, ultimately resulting in cost savings and reduced downtime. Whether in industrial settings, agricultural applications, or municipal water systems, understanding and utilizing pump seal kits is essential for optimal pump management.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories