Aug . 08, 2024 09:05 Back to list

Comprehensive Guide to Choosing the Right Pump Seal Kit for Your Needs and Applications

Understanding Pump Seal Kits Essential Components for Efficient Pump Operation

In various industrial applications, pumps serve as critical components that facilitate the movement of liquids and gases. From water treatment facilities to petrochemical refineries, the efficiency and reliability of these pumps are paramount. One crucial aspect that ensures optimal performance and longevity of pumps is the use of pump seal kits. This article delves into what pump seal kits are, their components, and the significance of regular maintenance in keeping pumps running smoothly.

What is a Pump Seal Kit?

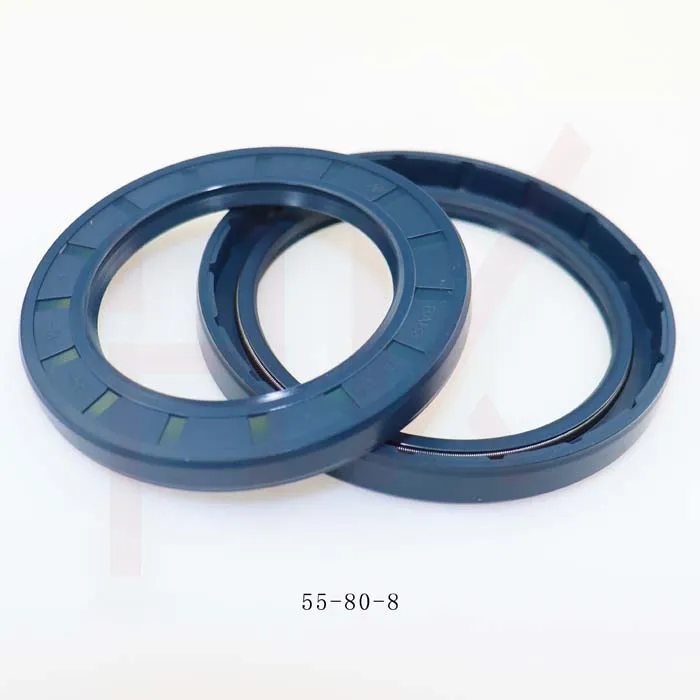

A pump seal kit is a collection of parts designed to prevent the leakage of fluids from the pump, ensuring that the environment surrounding the pump remains uncontaminated and safe. Seal kits typically include various components such as O-rings, gaskets, seal rings, and maybe mechanical seals, depending on the complexity of the pump design. Each component plays a specific role in maintaining a tight seal between different parts of the pump, thus preventing leaks and ensuring efficient operation.

Components of a Pump Seal Kit

1. O-Rings These are elastomeric rings that provide a reliable seal between moving and stationary parts. They are critical in preventing fluid leakage and can endure high pressures and temperatures.

2. Gaskets Usually made from softer materials, gaskets fill the gaps between flanges or other joint surfaces within the pump. They help to absorb vibrations and provide a secure seal to prevent leakage.

3. Seal Rings These may include both static and dynamic seals that provide contact points for sealing under pressure. Seal rings must be carefully selected based on the type of pump and the fluids being pumped.

4. Mechanical Seals In more complex pumps, mechanical seals are used to maintain the fluid within the pump and prevent it from escaping. These seals function through a combination of rotating and stationary components that create a barrier against leaks.

Importance of Pump Seal Kits

The significance of using pump seal kits cannot be overstated. A well-maintained seal kit ensures

- Leak Prevention One of the most critical functions of seal kits is to prevent leaks. Even minor leaks can lead to substantial losses of fluid, a decrease in pump performance, and more importantly, environmental hazards.

pump seal kit

- Cost Efficiency Regularly replacing worn-out components within seal kits can lead to reduced maintenance costs and downtime. Preventive maintenance is far less expensive than emergency repairs resulting from pump failures.

- Enhanced Pump Lifespan By safeguarding against leaks and wear, seal kits contribute to the overall longevity of the pump. This proactive approach means pumps can operate efficiently for extended periods, maximizing investment.

- Operational Safety In industries where hazardous materials are handled, pumps equipped with effective seal kits are crucial for ensuring the safety of workers and the surrounding environment.

Maintenance Tips for Pump Seal Kits

To maximize the effectiveness of pump seal kits, regular inspections and maintenance are crucial. Here are a few best practices

- Routine Checks Periodically inspect the seal components for signs of wear and tear, especially in applications with high pressures or abrasive fluids.

- Proper Installation Ensure that seals are installed correctly and uniformly. Misalignment during installation can lead to premature failure.

- Replacement Schedule Establish a maintenance schedule that includes regular replacement of seal kits based on manufacturer recommendations and usage conditions.

- Monitor Performance Keeping an eye on pump performance can help detect early signs of leaks or inefficiencies, allowing for prompt intervention.

Conclusion

Pump seal kits are fundamental to the efficient operation of pumps in various industries. By understanding their components and the importance of regular maintenance, operators can ensure that their pumps remain reliable, cost-effective, and safe for the environment. Investing in high-quality seal kits and adhering to a strict maintenance routine can significantly enhance pump performance and longevity, thereby optimizing operational effectiveness in any industry.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories